Configure Controls for Mechanized Cutting

100 809240 Operator Manual Powermax45 XP

Installation of the machine interface cable

Installation of the machine interface cable must be performed by a qualified service technician. To

install a machine interface cable:

1. Turn O F F (O) the power and disconnect the power cord.

2. Remove the machine interface receptacle’s cover from the rear of the power supply.

3. Connect the Hypertherm machine interface cable to the power supply.

4. If you are using a cable with a D-sub connector on the other end:

a. Plug it into the appropriate pin connector on the torch height controller or CNC.

b. Secure it with the screws on the D-sub connector.

If you are using a cable with wires and spade connectors on the other end:

a. Terminate the machine interface cable inside the electrical enclosure of the torch height

controller or CNC controller. This prevents unauthorized access to the connections after

installation.

b. Verify that the connections are correct and that all live parts are enclosed and protected

before operating the equipment.

The integration of Hypertherm equipment and customer-supplied

equipment including interconnecting cords and cables, if not listed and

certified as a system, is subject to inspection by local authorities at the

final installation site.

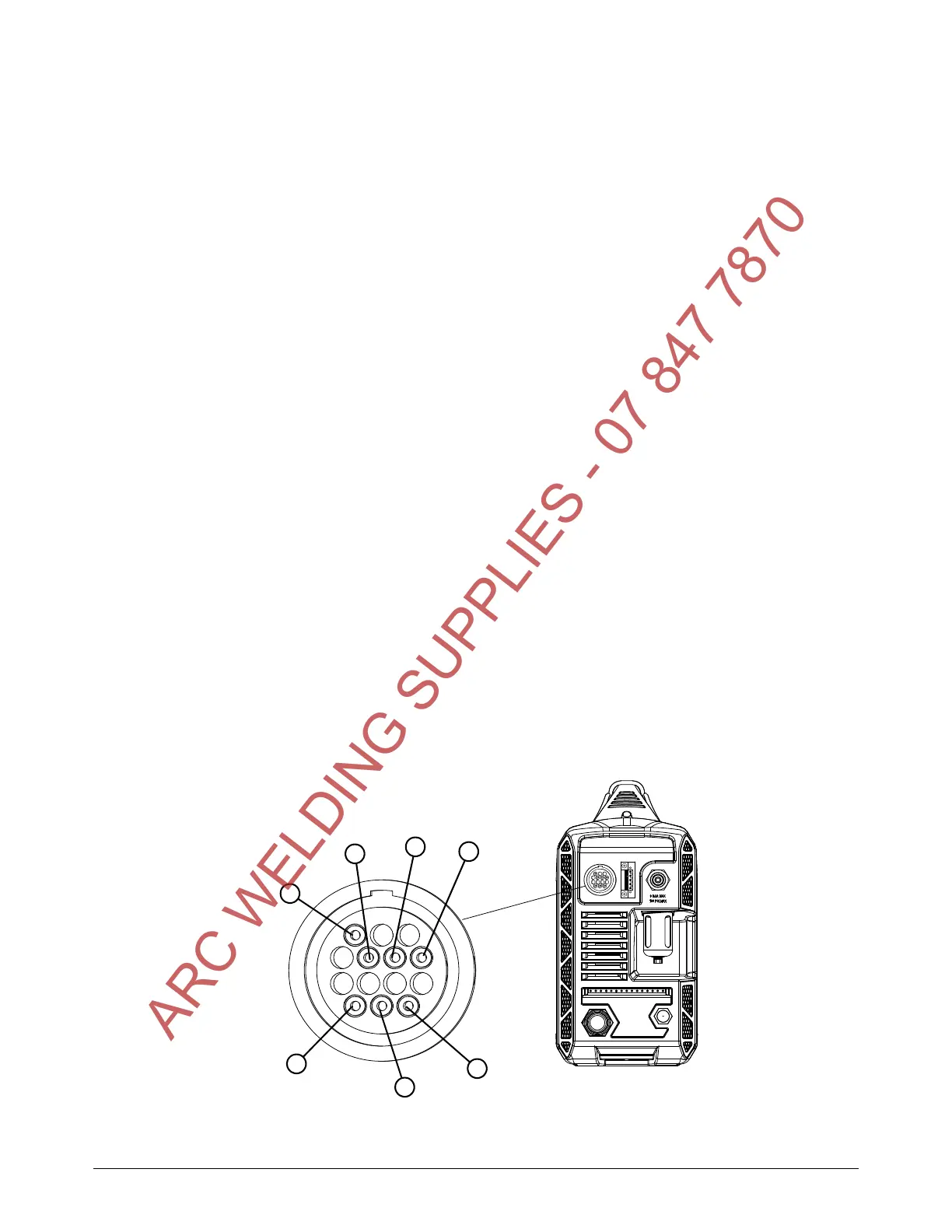

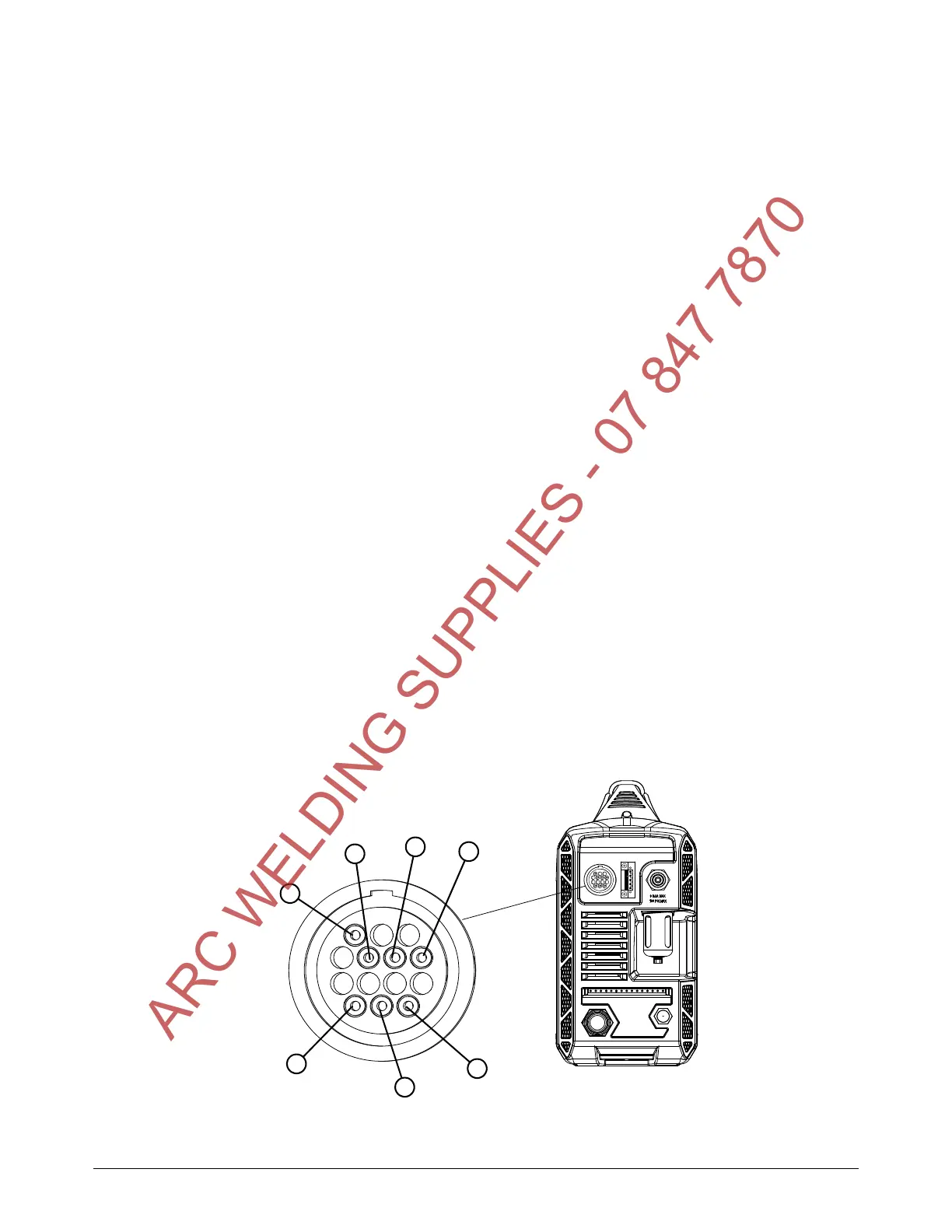

Machine interface pinout

The following figure shows the connector sockets for each type of signal available through the

machine interface cable.

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...