Guidelines for Marking

120 809240 Operator Manual Powermax45 XP

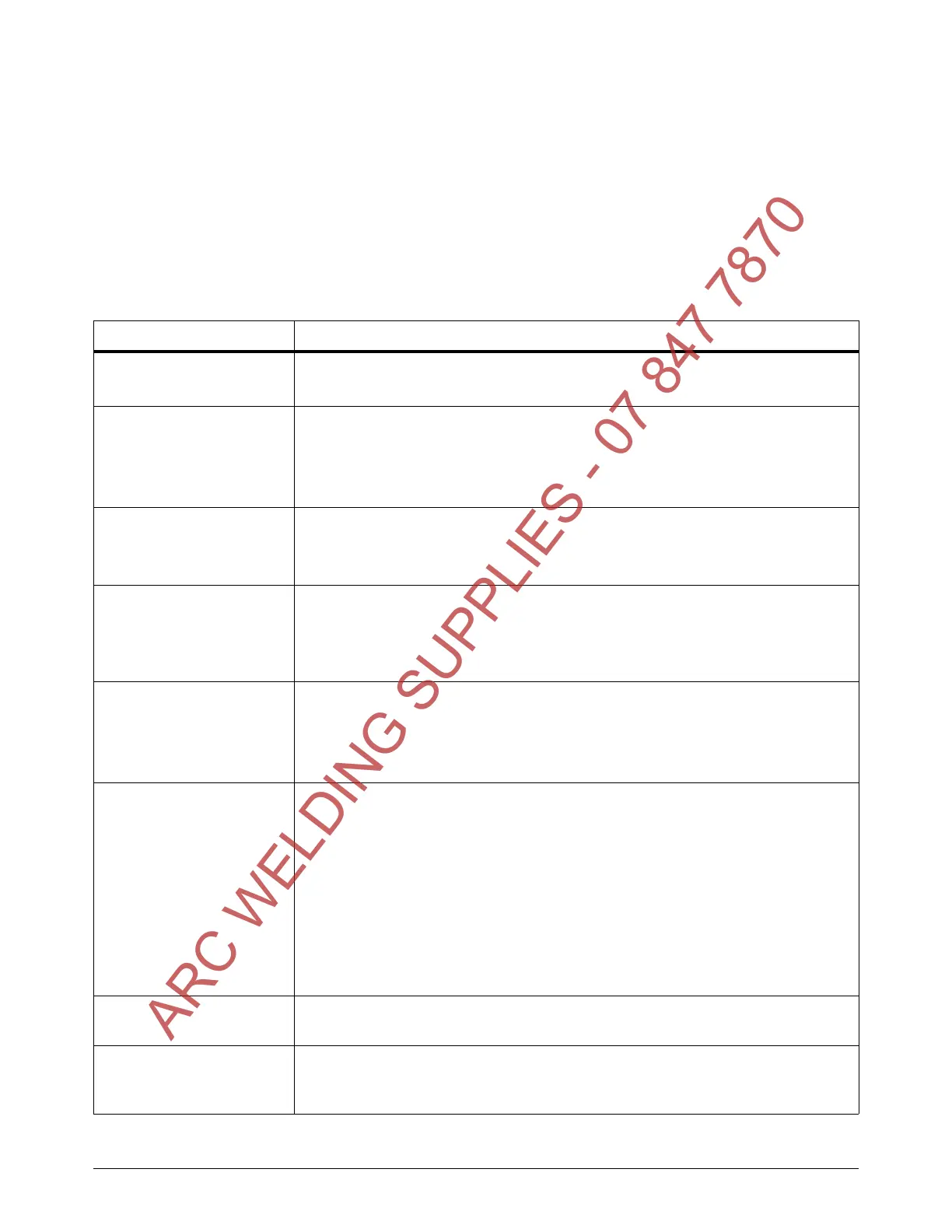

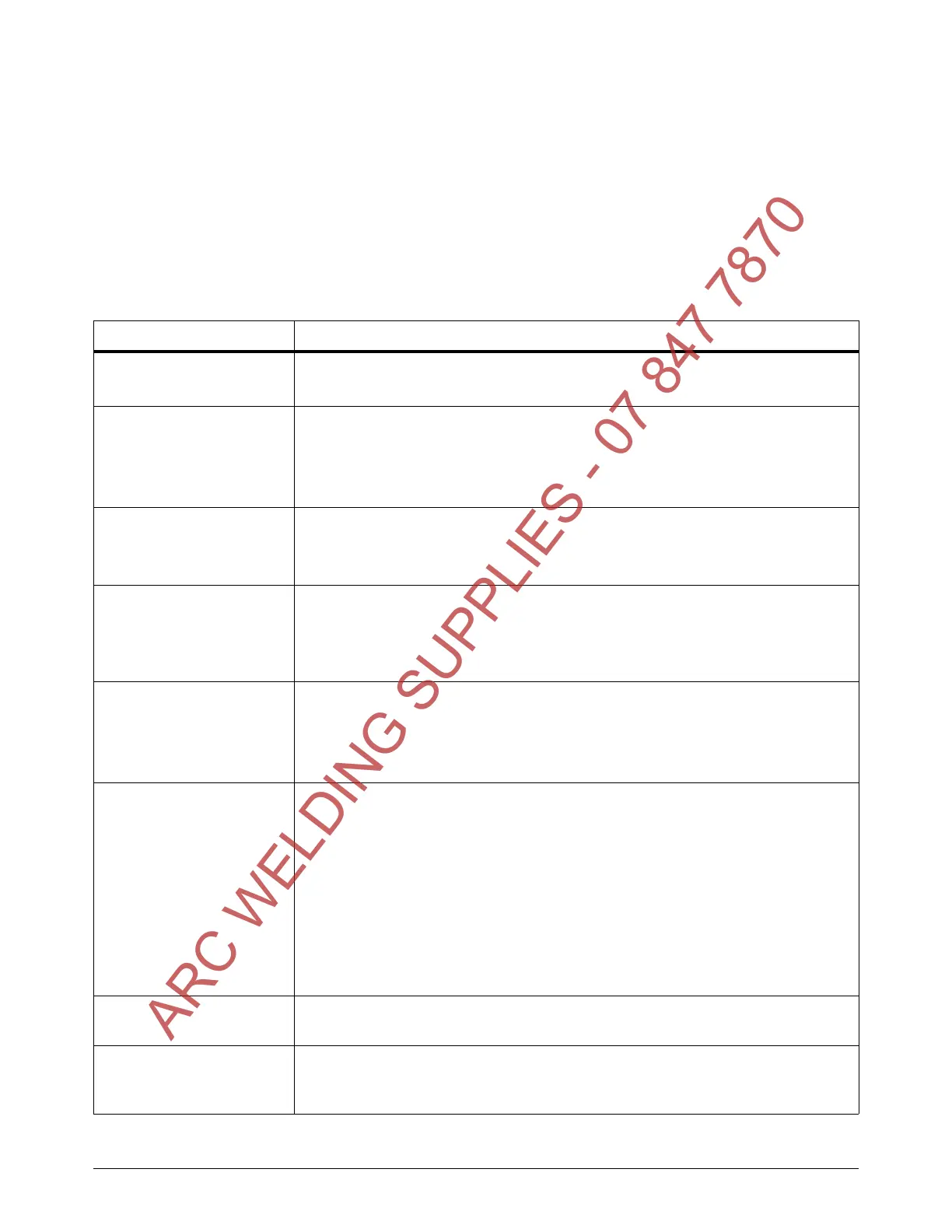

Common marking problems and solutions

For marking applications, always make sure:

The Marking consumables are installed.

The power supply is set to Gouge/Marking mode, and the output current is set between

10 – 25 A.

Many common marking issues can be resolved by installing new consumables in the torch. Do not

use worn or damaged consumables. See page 154.

Problem Solution

The arc goes out during

marking.

• Make sure that the torch-to-work distance (standoff) is not too high.

• Change worn or damaged consumables. See page 154.

The dimple diameter is

wrong.

• For a larger diameter dimple, increase the output current.

• For a smaller diameter dimple, decrease the output current.

• Adjust the torch-to-work distance (standoff).

• Change worn or damaged consumables. See page 154.

The dimple depth is wrong. • For a deeper dimple, increase the dwell time.

• For a shallower dimple, decrease the dwell time (if possible).

• Adjust the torch-to-work distance (standoff).

The mark is too wide or too

deep.

• Decrease the output current.

• Increase the marking speed.

• Inspect the consumables, especially the center hole of the nozzle. Change

worn or damaged consumables. See page 154.

The mark is too narrow or

too shallow.

• Change worn or damaged consumables. See page 154.

• Increase the output current.

• Decrease the marking speed.

• Decrease the torch height.

The beginning of the mark

is too large.

• If the delay time between when the CNC receives the machine motion signal

and when the machine motion actually occurs is significant, piercing may

occur. If possible, decrease the delay time to 0 (zero).

• Check the table parameters, especially the acceleration parameter. It may need

to be increased.

• Decrease the output current to reduce the size of the dimple at the beginning

of the mark. The marking speed may also need to be adjusted for the lower

output current.

• Check the torch-to-work distance (standoff) to make sure there is a good, fast

transfer of the plasma arc to the workpiece.

The end of the mark is too

large.

• Check the cutting table parameters. If possible, increase the deceleration

parameter.

The mark becomes too

deep and too wide during

cornering.

• You may need to try a different method for cornering. See page 119.

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...