Cut Charts and Marking Charts

Powermax45 XP Operator Manual 809240 131

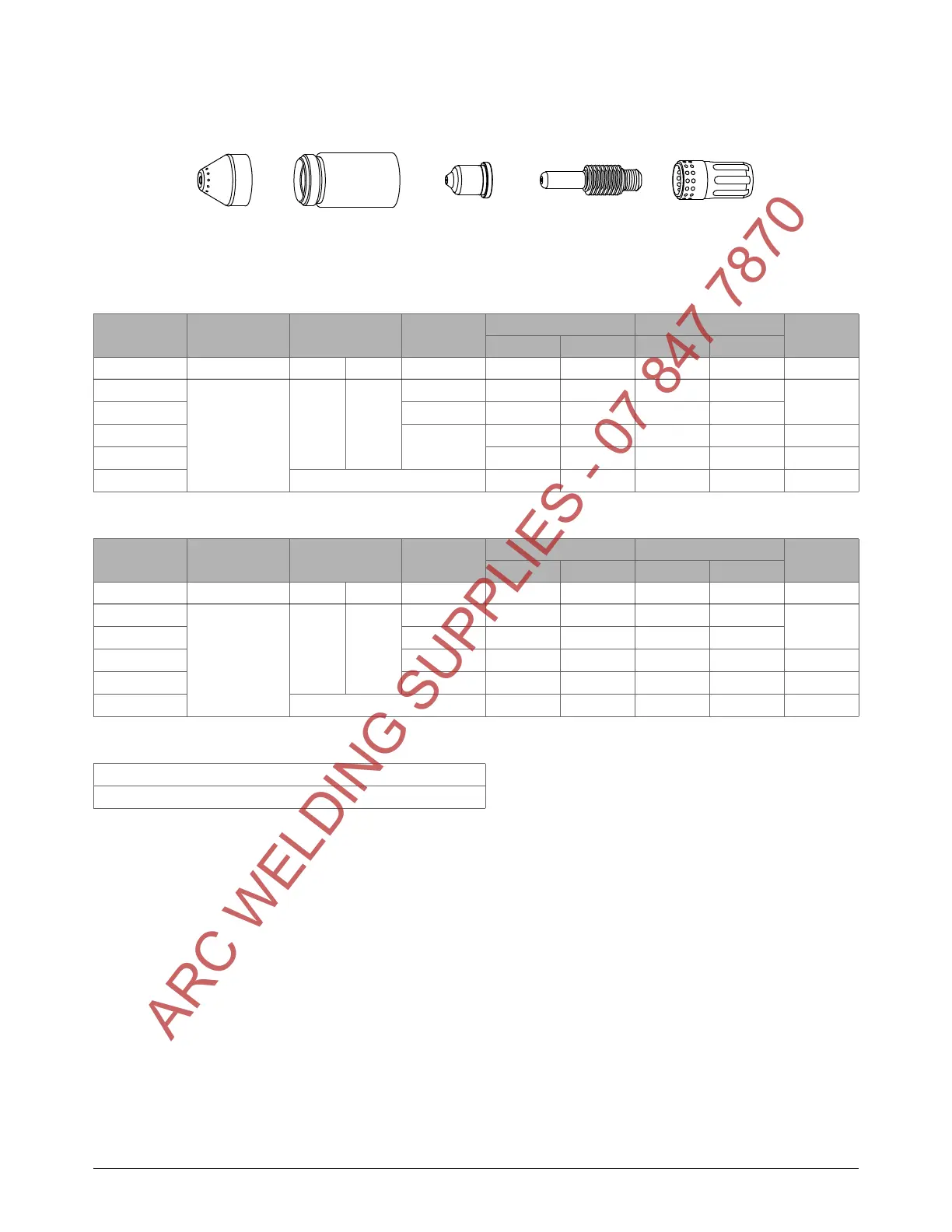

Stainless Steel – 45 A – F5 – Shielded

F5 is not recommended for thicknesses less than 3 mm (10 GA).

Metric

Material

Thickness

Torch-to-Work

Distance

Initial Pierce Height

Pierce

Delay Time

Best Quality Settings Production Settings

Kerf Width

Cut Speed Voltage Cut Speed Voltage

mm mm mm % seconds mm/min volts mm/min volts mm

4

1.5

3.8 250

0.5 1550 139 2820 136

1.7

6 0.6 910 146 1380 140

8

0.8

630 150 860 144 2.1

10 435 153 525 147 2.3

12 Edge Start 340 156 440 150 2.5

English

Material

Thickness

Torch-to-Work

Distance

Initial Pierce Height

Pierce

Delay Time

Best Quality Settings Production Settings

Kerf Width

Cut Speed Voltage Cut Speed Voltage

inches inches inches % seconds in/min volts in/min volts inches

10 GA

0.06

0.15 250

0.4 70 137 119 135

0.069

3/16 0.5 49 142 80 138

1/4 0.6 32 147 47 141 0.082

3/8 0.8 18 152 22 146 0.090

1/2 Edge Start 12 157 16 151 0.098

Gas flow rate – slpm / scfh

149 / 315 Hot (cutflow)

184 / 390 Cold (postflow)

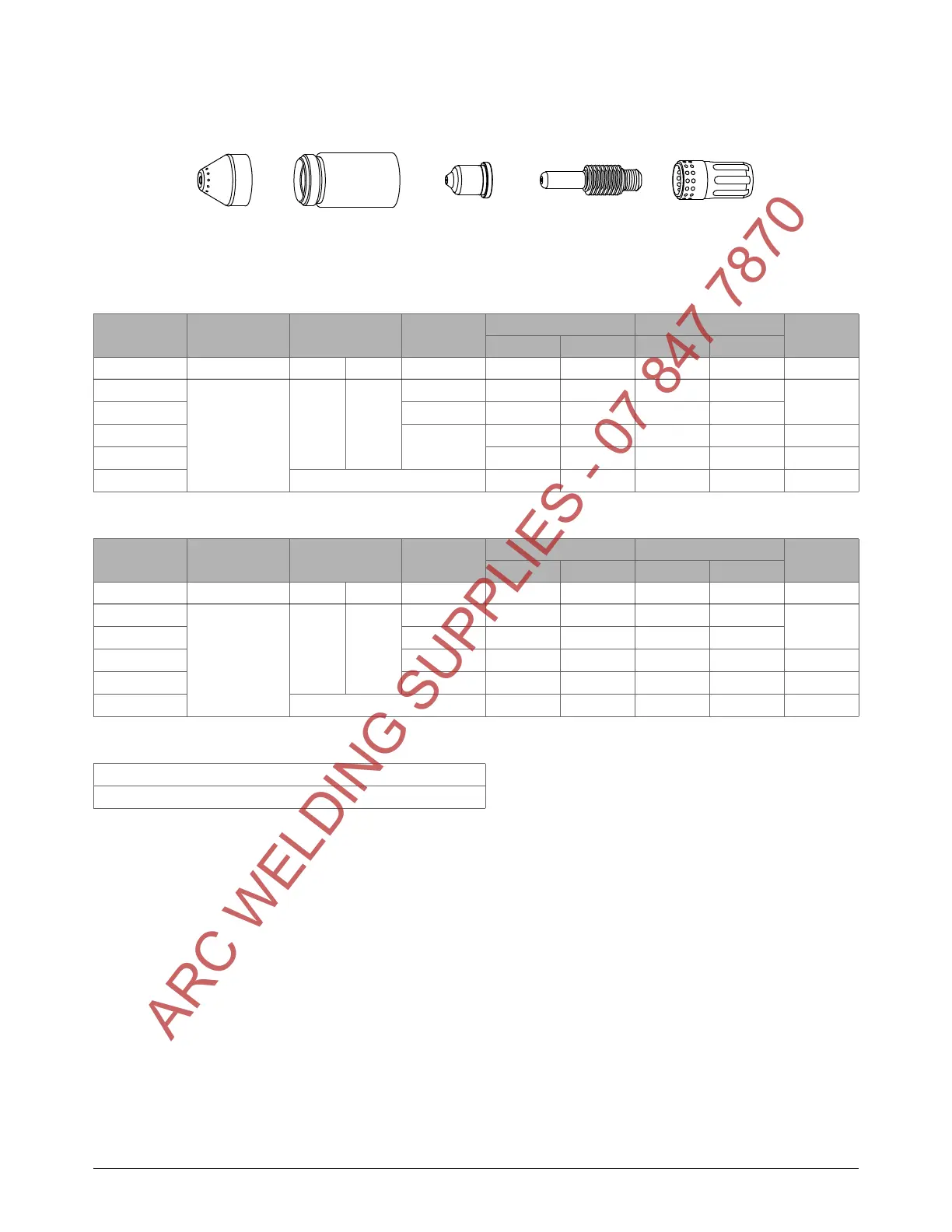

220817 220854

(220953 for

ohmic sensing)

220941 220857220842

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...