Gouge with the Hand Torch and Machine Torch

74 809240 Operator Manual Powermax45 XP

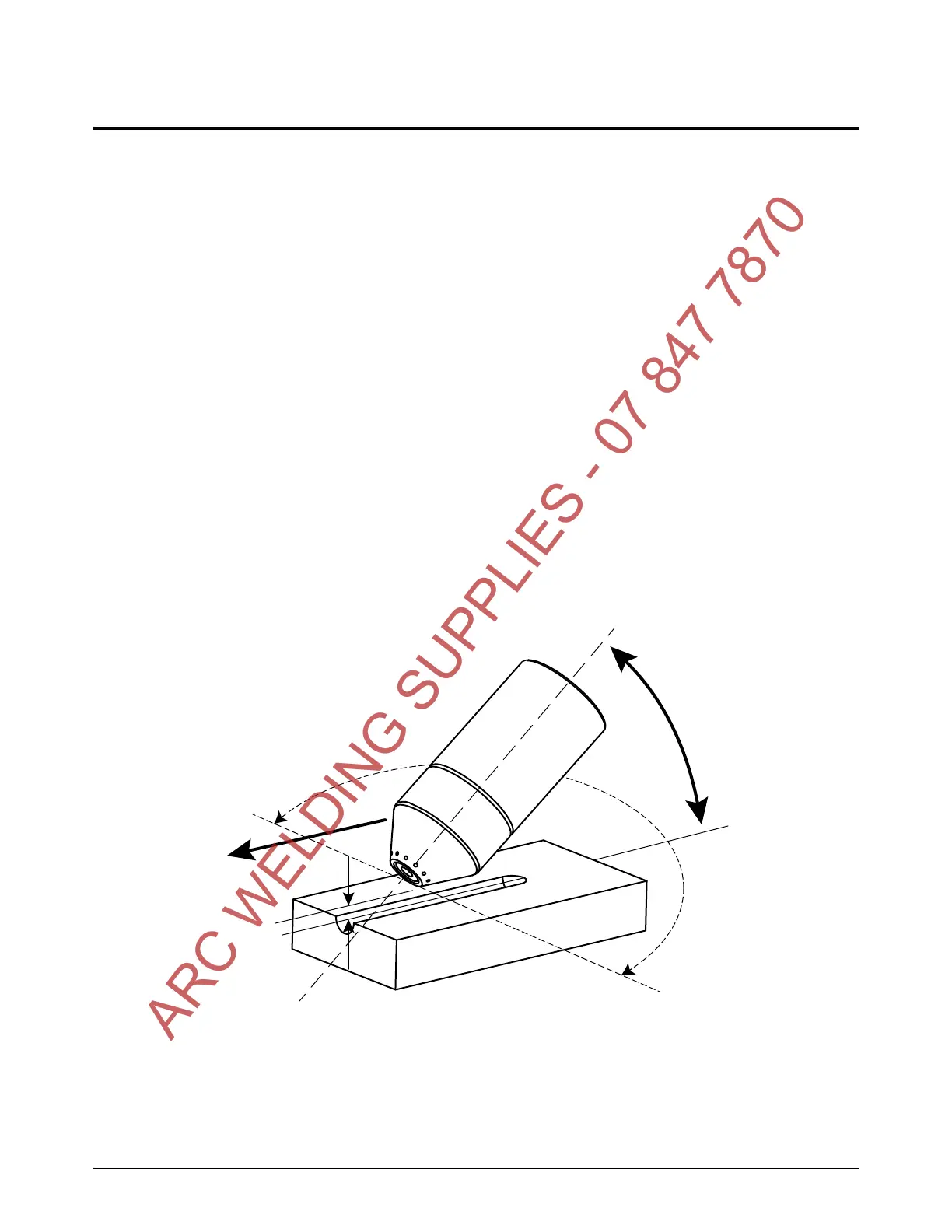

How to control the gouge profile

The following factors affect the width and the depth of the gouge profile. Adjust these elements to

achieve the gouge you need.

Output current of the plasma power supply – Turn down the amperage on the front panel

to make the gouge narrower and more shallow.

If you are using the Maximum Control gouging consumables, keep the amperage

between 26 – 45 A.

If you are using the Precision gouging consumables, keep the amperage between

10 – 25 A.

Angle of the torch to the workpiece – Position the torch in a more upright position to

make the gouge narrower and deeper. Tilt down the torch so that it is closer to the

workpiece to make the gouge wider and more shallow.

Rotation of the torch – Rotate the torch relative to the torch center line to make the gouge

flatter and steeper on one side.

Torch-to-work standoff – Move the torch further away from the workpiece to make the

gouge wider and more shallow. Move the torch closer to the workpiece to make the gouge

narrower and deeper.

Speed of the torch over the workpiece – Slow down to make the gouge wider and

deeper. Speed up to make the gouge narrower and more shallow.

Standoff

Angle

Rotation of torch (relative

to torch center line)

Torch center line

Speed

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...