Cut Charts and Marking Charts

Powermax45 XP Operator Manual 809240 133

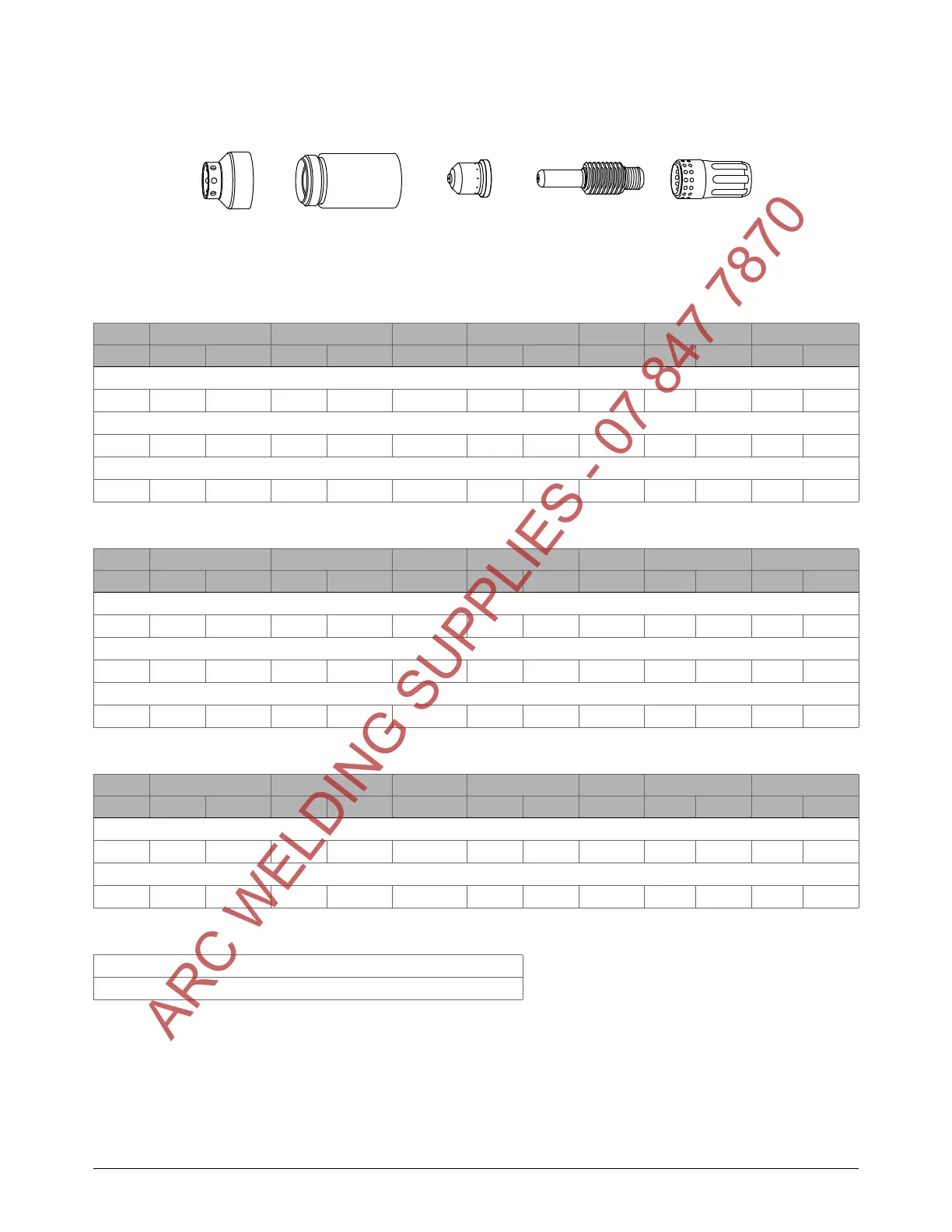

Marking and Dimpling – Argon – Shielded

Mild steel

Current Torch-to-Work Distance Initial Marking Height Delay Time Marking Speed Arc Voltage Width Depth

A mm in mm in seconds mm/min in/min volts mm in mm in

Light marking

10 2.0 0.08 2.0 0.08 0 3175 125 44 1.22 0.048 <0.02 <0.001

Heavy marking

15 1.5 0.06 1.5 0.06 0 3175 125 44 1.22 0.048 <0.02 <0.001

Dimpling

20 3.2 0.125 — — 0.2 — — — 0.99 0.039 <0.02 <0.001

Stainless steel

Current Torch-to-Work Distance Initial Marking Height Delay Time Marking Speed Arc Voltage Width Depth

A mm in mm in seconds mm/min in/min volts mm in mm in

Light marking

12 2.5 0.1 2.5 0.1 0 3175 125 46 1.40 0.055 <0.02 <0.001

Heavy marking

15 2.5 0.1 2.5 0.1 0 2540 100 46 2.16 0.085 0.02 0.001

Dimpling

10 3.2 0.125 — — 0.2 — — — 0.94 0.037 0.18 0.007

Aluminum

Current Torch-to-Work Distance Initial Marking Height Delay Time Marking Speed Arc Voltage Width Depth

A mm in mm in seconds mm/min in/min volts mm in mm in

Marking

16 0.5 0.02 0.5 0.02 0 4445 175 42 0.63 0.025 <0.02 <0.001

Dimpling

20 0.5 0.02 — — 0.4 — — — 0.66 0.026 0.04 0.0015

Gas flow rate – slpm / scfh

120 / 255 Hot (cutflow)

123 / 260 Cold (postflow)

420542 220854

(220953 for

ohmic sensing)

420415 220857220842

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...