Installation and Setup

Powermax45 XP Operator Manual 809240 35

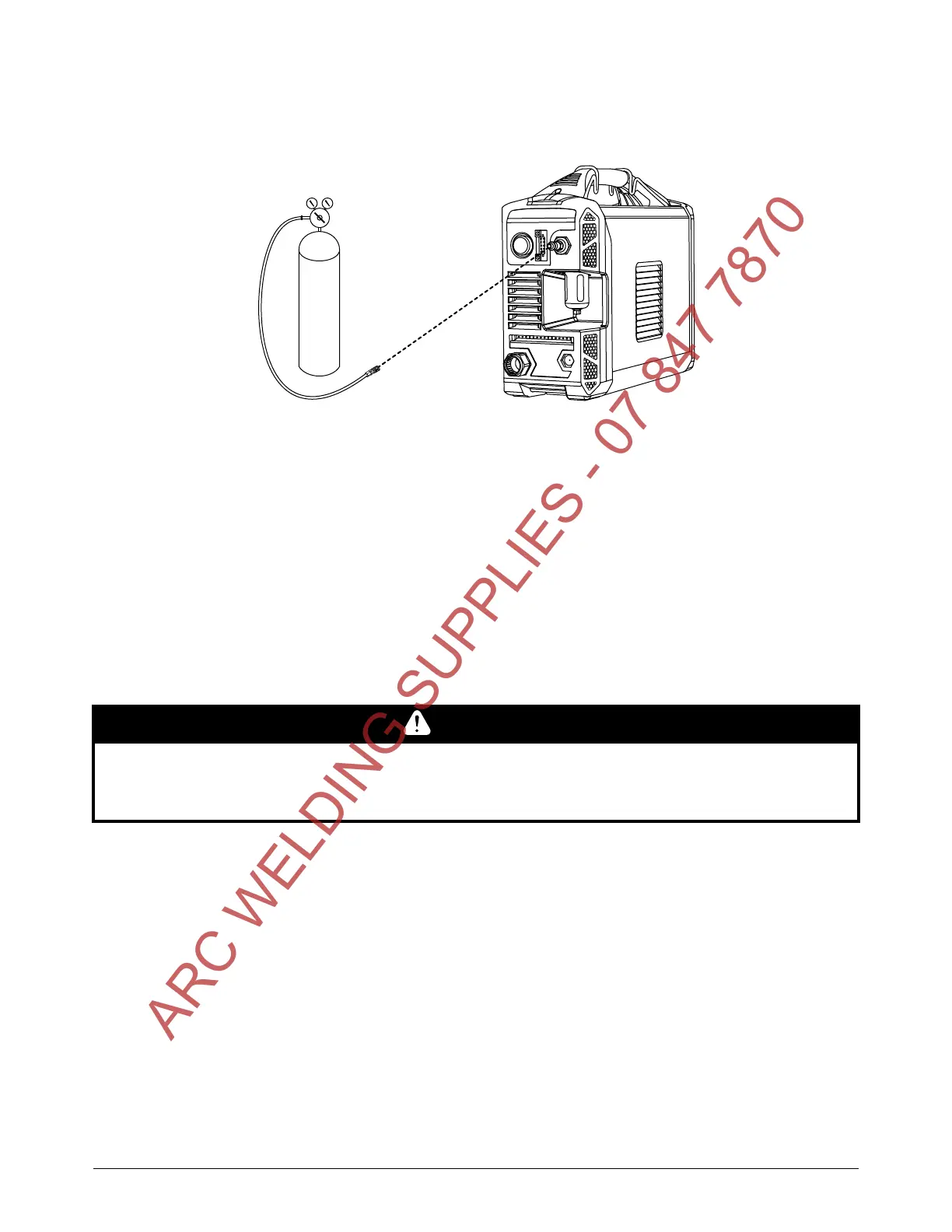

Gas supply source

Use shop-compressed gas or cylinder-compressed gas.

Use a high-pressure regulator on either type of gas supply. The regulator must be

capable of delivering gas to the air inlet on the power supply at the flow rate and

pressure specified above.

Use only clean, moisture-free gas.

Oil, water, vapor, and other contaminants in the gas supply can damage internal

components over time.

Poor gas supply quality results in:

Reduced cut quality and cut speeds

Reduced cut thickness capability

Reduced consumable life

CAUTION

Synthetic lubricants containing esters that are used in some air compressors will damage

polycarbonates used in the air filter bowl.

Recommended gas supply pressure: 5.5 – 6.9 bar (80 – 100 psi)

Maximum gas supply pressure: 9.3 bar (135 psi)

Recommended flow rate and pressure: 189 slpm at 5.9 bar (400 scfh at 85 psi)

Minimum flow rate: 165.2 slpm (350 scfh)

Maximum particle size: 0.1 micron at maximum concentration of 0.1 mg/m3*

Maximum water vapor dewpoint: -40°C (-40°F)

Maximum oil concentration: 0.1 mg/m3 (for aerosol, liquid, and vapor)

* Per ISO8573-1:2010, Class 1.2.2. That is, it should have a maximum number of solid particulate per meter cubed

of 20,000 for particle sizes in the range of 0.1 – 0.5 microns, a maximum of 400 for particle sizes in the range of

0.5 – 1 microns, and a maximum of 10 for particle sizes in the range of 1 – 5 microns.

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...