Guidelines for Marking

11 4 809240 Operator Manual Powermax45 XP

Process gas: air versus argon

With this system and torch, you can use air or argon for marking applications.

How the system handles postflow for marking

Postflow is gas that flows from the torch in order to cool the consumables after the plasma arc

extinguishes. When you use air (or nitrogen) for marking applications, the duration of postflow is

10 seconds. The system recognizes when argon is being used and decreases postflow from

10 seconds to 3 seconds in order to minimize gas usage. To achieve 3-second postflow:

The system must be set to Gouge/Marking mode.

The output current must be set to 10 – 25 A.

The plasma arc must be sustained for a minimum of 0.5 seconds.

There are 2 scenarios in which postflow is 10 seconds even when argon is used because the

plasma arc is not sustained long enough to produce 3-second postflow:

When the torch fires without transferring the pilot arc to the workpiece

In some dimpling applications where the plasma arc is sustained for less than 0.5 seconds

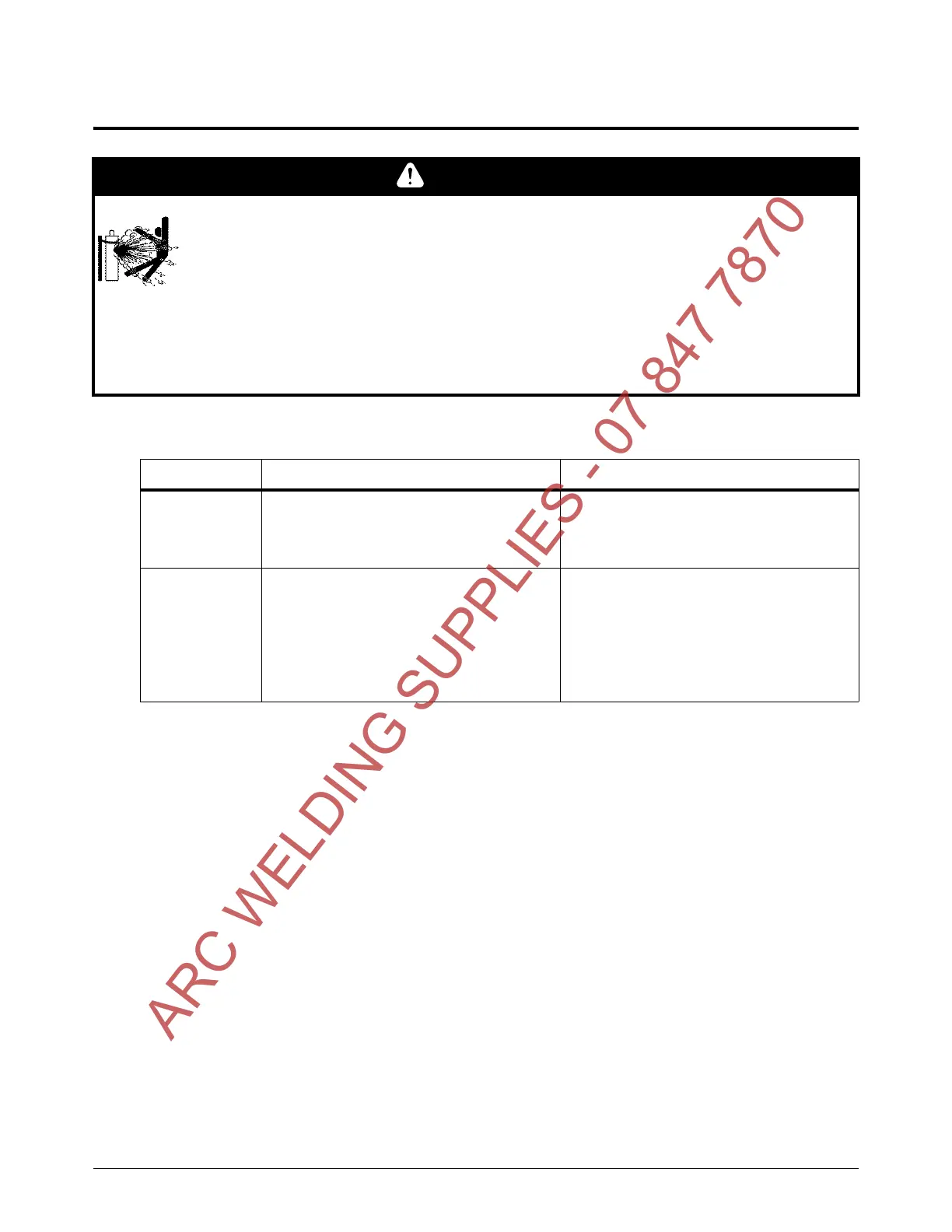

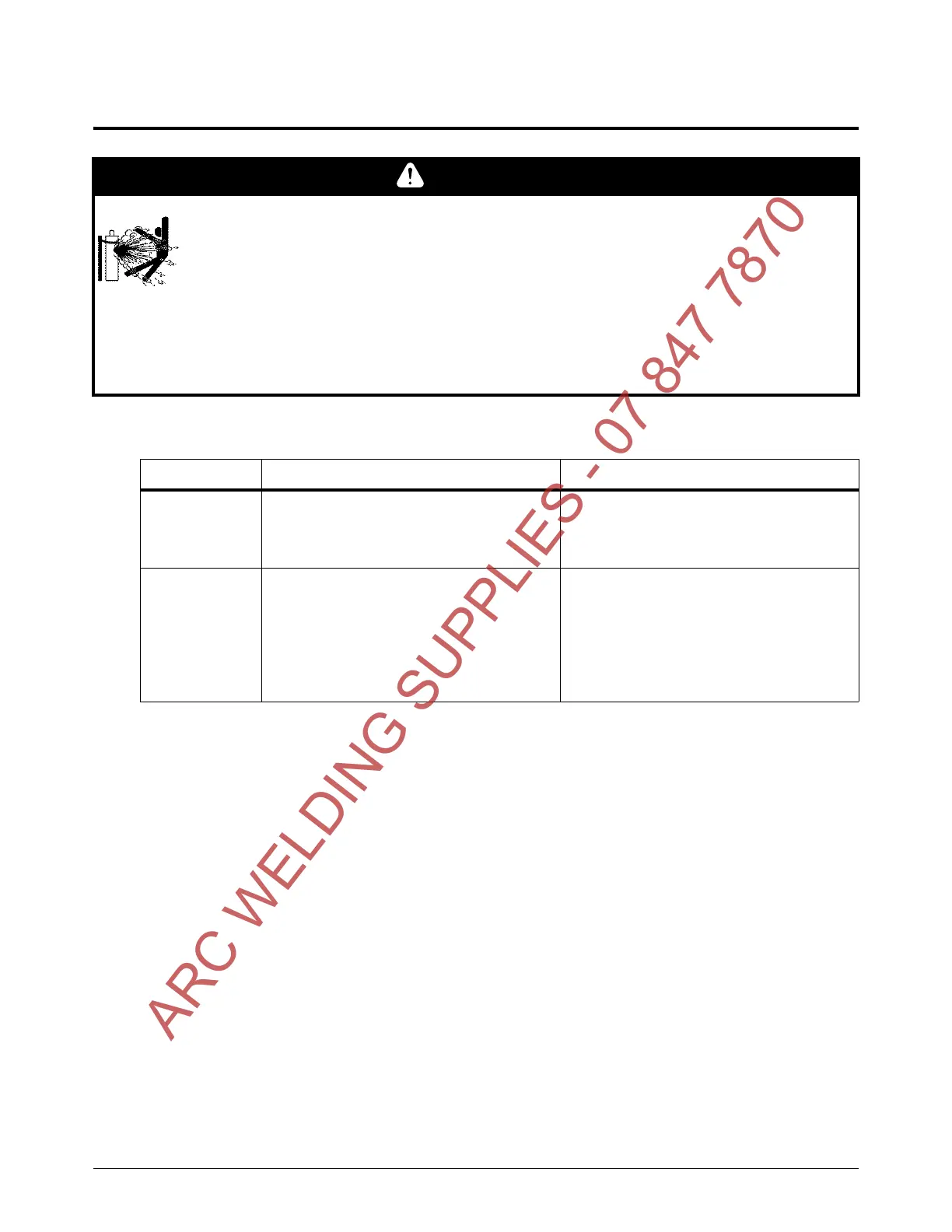

WARNING

GAS CYLINDERS CAN EXPLODE IF DAMAGED

Gas cylinders contain gas under high pressure. If damaged, a cylinder can explode.

For high pressure regulators, adhere to the manufacturer’s guidelines for safe

installation, operation, and maintenance.

Before plasma cutting with compressed gas, read the safety instructions in the

Safety and Compliance Manual (80669C). Failure to follow safety instructions can

result in personal injury or in damage to equipment.

Air Argon

Advantages

•Low cost

• Excellent all around process

• Little or no top-side slag on mild steel

• Low heat input lessens chance of

material deformation

• Excellent high contrast for light scoring

Disadvantages

• High heat input, especially on thin

metal; may cause material deformation

• Mark edges may appear jagged on

aluminum

• More dross and wider marks than with

argon

• More expensive than air (see How the

system handles postflow for marking

below)

• Heavy scoring leaves top-side slag on

steel

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...