Cut Charts and Marking Charts

Powermax45 XP Operator Manual 809240 127

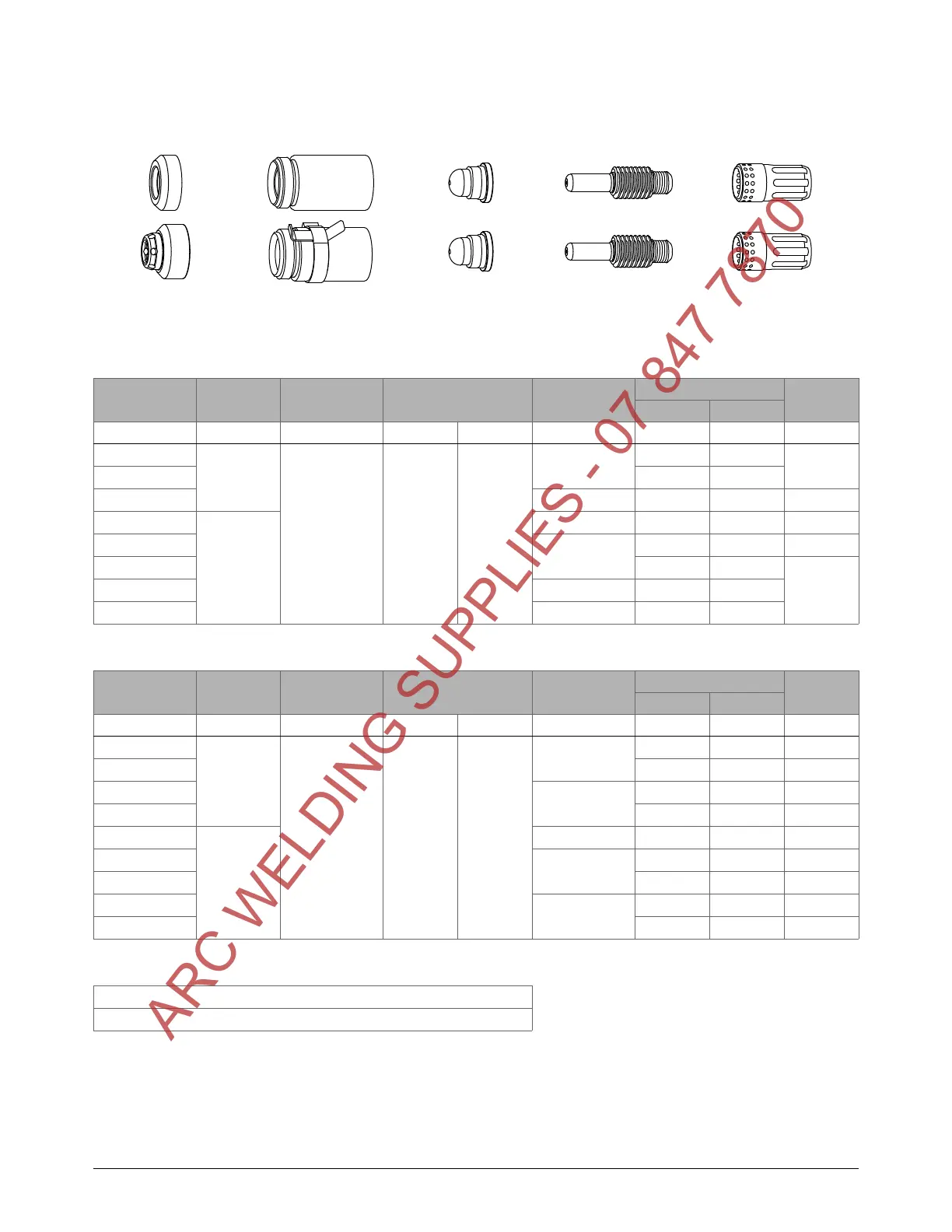

Mild Steel – FineCut – Air – Shielded and Unshielded

Metric

Material Thickness Current

Torch-to-Work

Distance

Initial Pierce Height Pierce Delay Time

Recommended

Kerf Width

Cut Speed Voltage

mm A mm mm % seconds mm/min volts mm

0.5

40

1.5 3.8 250

0.0

8250 78

0.7

0.6 8250 78

0.8 0.1 8250 78 0.6

1

45

0.2 8250 78 0.7

1.5

0.4

6400 78 1.2

2 5250 82

1.330.5275083

4 0.6 1900 84

English

Material Thickness Current

Torch-to-Work

Distance

Initial Pierce Height Pierce Delay Time

Best Quality Settings

Kerf Width

Cut Speed Voltage

inches A inches inches % seconds in/min volts inches

26 GA

40

0.06 0.15 250

0.0

325 78 0.025

24 GA 325 78 0.029

22 GA

0.1

325 78 0.024

20 GA 325 78 0.020

18 GA

45

0.2 325 78 0.043

16 GA

0.4

250 78 0.046

14 GA 220 82 0.049

12 GA

0.5

120 83 0.052

10 GA 95 84 0.051

Gas flow rate – slpm / scfh

155 / 330 Hot (cutflow)

215 / 460 Cold (postflow)

220955 (deflector)

220948 (shield)

220854

220953 (ohmic)

220930 220857220842

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...