Set Up the Machine Torch

92 809240 Operator Manual Powermax45 XP

Assemble the machine torch

If you disassembled the torch to route it through the cutting table’s track or other mounting system,

use the following procedure to reassemble the torch.

While disconnecting and reconnecting the torch parts, do not twist the

torch or the lead. Maintain the same orientation between the torch head

and torch lead. Twisting the torch head in relation to the torch lead can

cause damage to the torch wires.

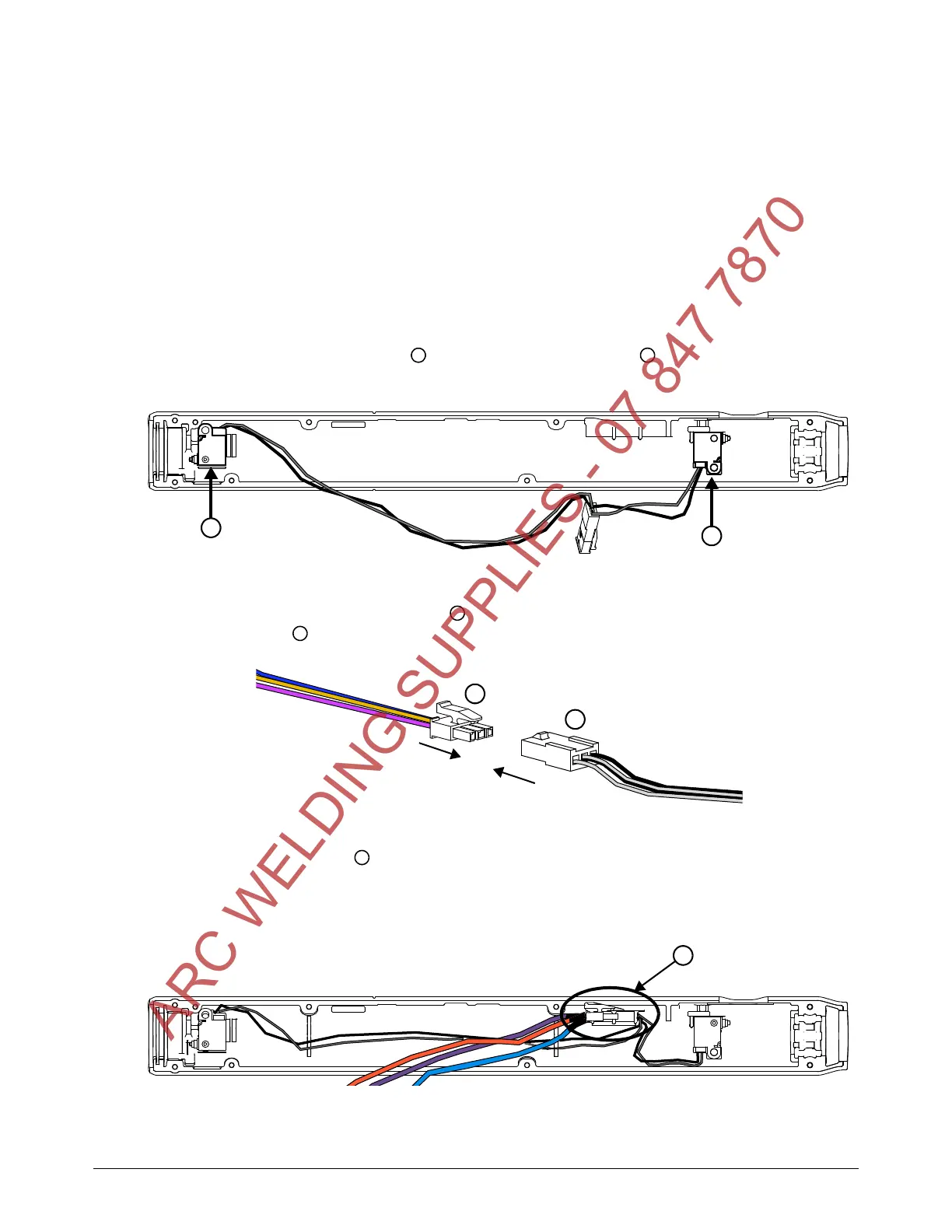

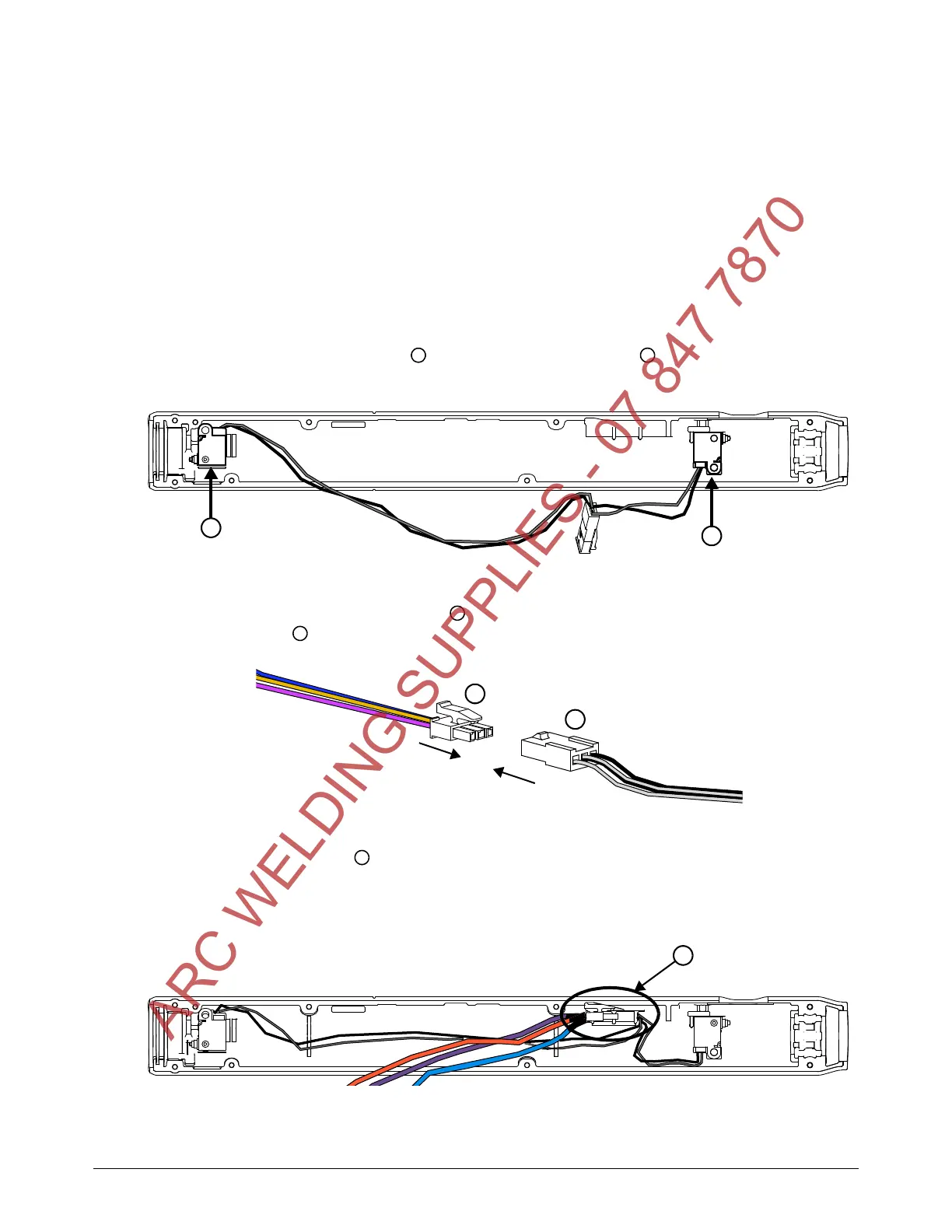

1. Place the right torch shell on a flat surface.

2. Make sure the cap-sensor switch and the torch-disable switch sit in the right torch shell as

shown. Mounting posts in the torch shell hold each switch in place.

3. Connect the wires from the torch body to the wires from the cap-sensor switch/torch-disable

switch assembly .

4. Place the wire connector on the mounting shelf in the right torch shell as shown.

Route the blue and black wires from the cap-sensor switch and the torch-disable switch outside

of and below the mounting shelf. This helps to prevent the wires from getting pinched and

damaged when the torch is fully assembled.

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...