Cut with the Machine Torch

Powermax45 XP Operator Manual 809240 111

Cut stainless steel with F5

You can use F5 gas to cut stainless steel with Duramax Lock torches on the Powermax45 XP. When

used with a Powermax system, F5 is recommended only for cutting stainless steel to achieve to the

advantages in cut quality listed below.

See page 131 for a cut chart on cutting stainless steel with F5.

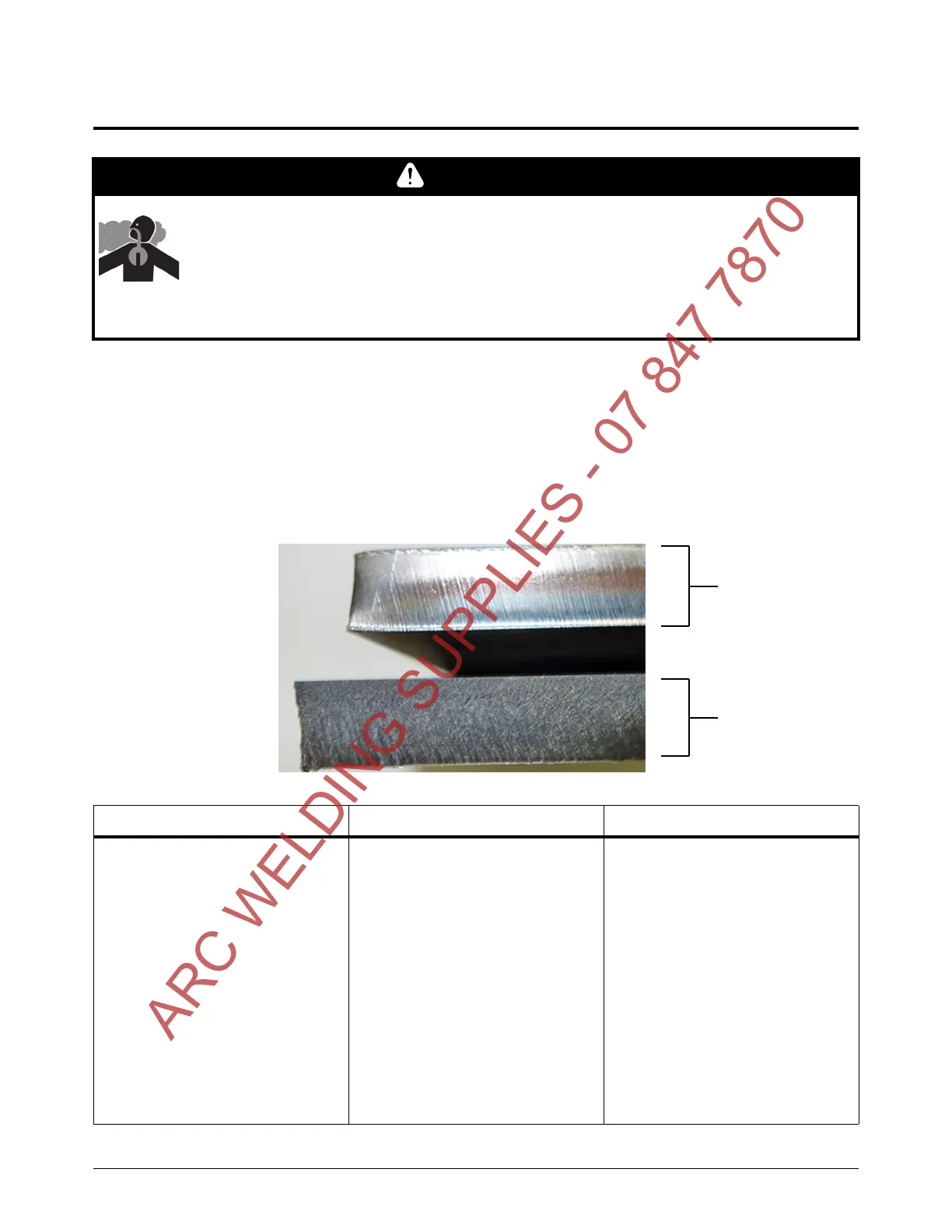

Plasma cutting with F5 produces smooth, shiny cuts with silver edges that are close to the base

color of the metal. F5 avoids the rough, dark finish that typically results with air plasma cutting.

WARNING

TOXIC FUMES CAN CAUSE INJURY OR DEATH

Some metals, including stainless steel, may release toxic fumes when cut. Make sure

your work site has adequate ventilation to ensure that the air quality level meets all

local and national standards and regulations. Refer to the Safety and Compliance

Manual (80669C) for more information.

F5: Advantages F5: Disadvantages F5: Similarities to air

• Smooth, shiny cut edge

• Silver cut edge, similar to the

base color of the metal – does

not leave the rough, dark

surface that air produces

• No oxidation of the cut

surface – the cut steel

maintains its corrosion

resistance

• Ability to use the same

Duramax Lock consumables as

for standard cutting and

gouging with air (includes

CopperPlus™ electrodes)

• Advantages limited to stainless

steel

•Slower cut speeds

• F5 gas is more expensive than

compressed air

• Not recommended for

thicknesses less than 3 mm or

10 gauge (GA) or for use with

FineCut

®

consumables

• Slightly degraded cut quality on

bevel cuts

• Approximately the same

amount of dross. With F5 and

with air, stainless steel dross is

dark in color and can be

challenging to remove.

• Approximately the same gas

pressure requirements

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...