Cut with the Machine Torch

Powermax45 XP Operator Manual 809240 107

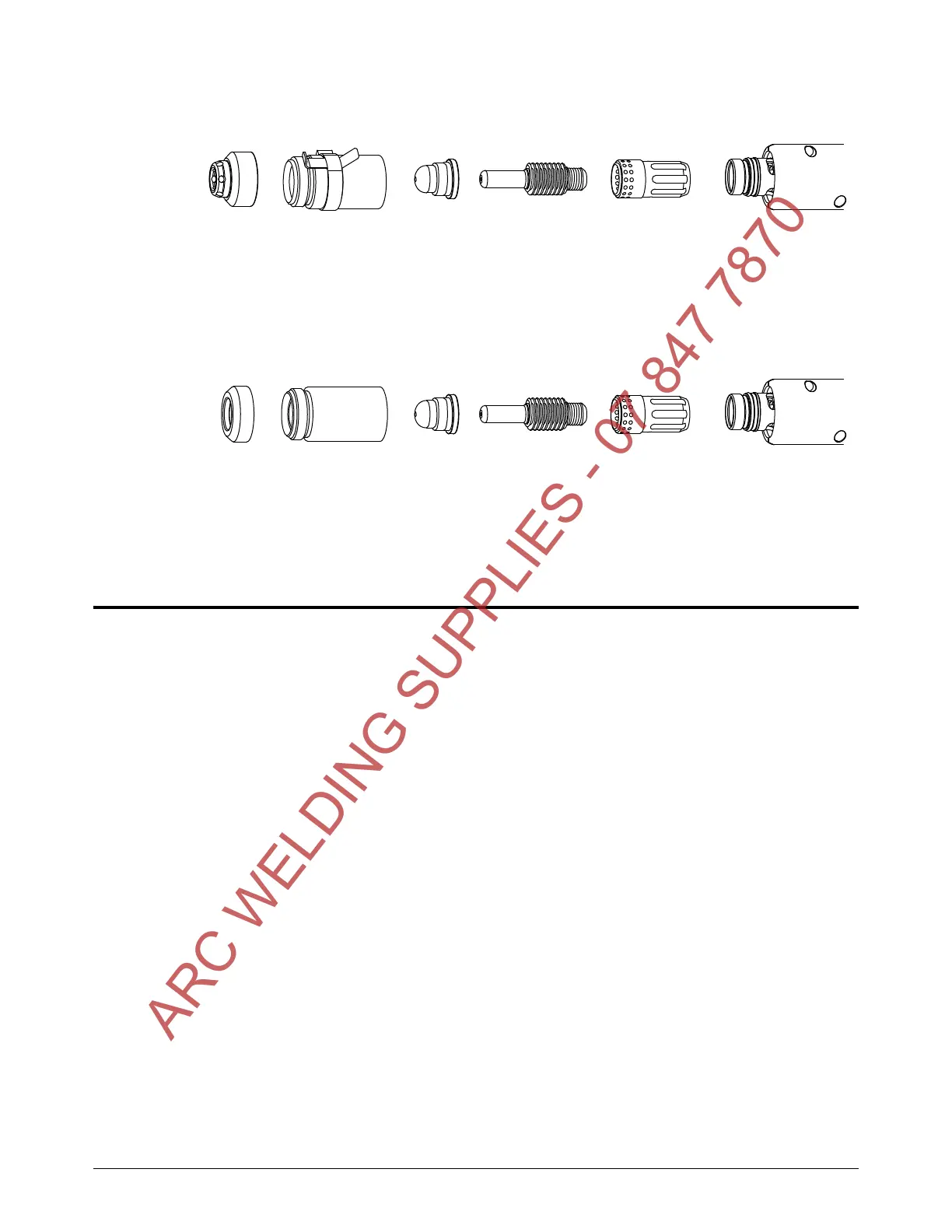

FineCut shielded consumables with ohmic retaining cap

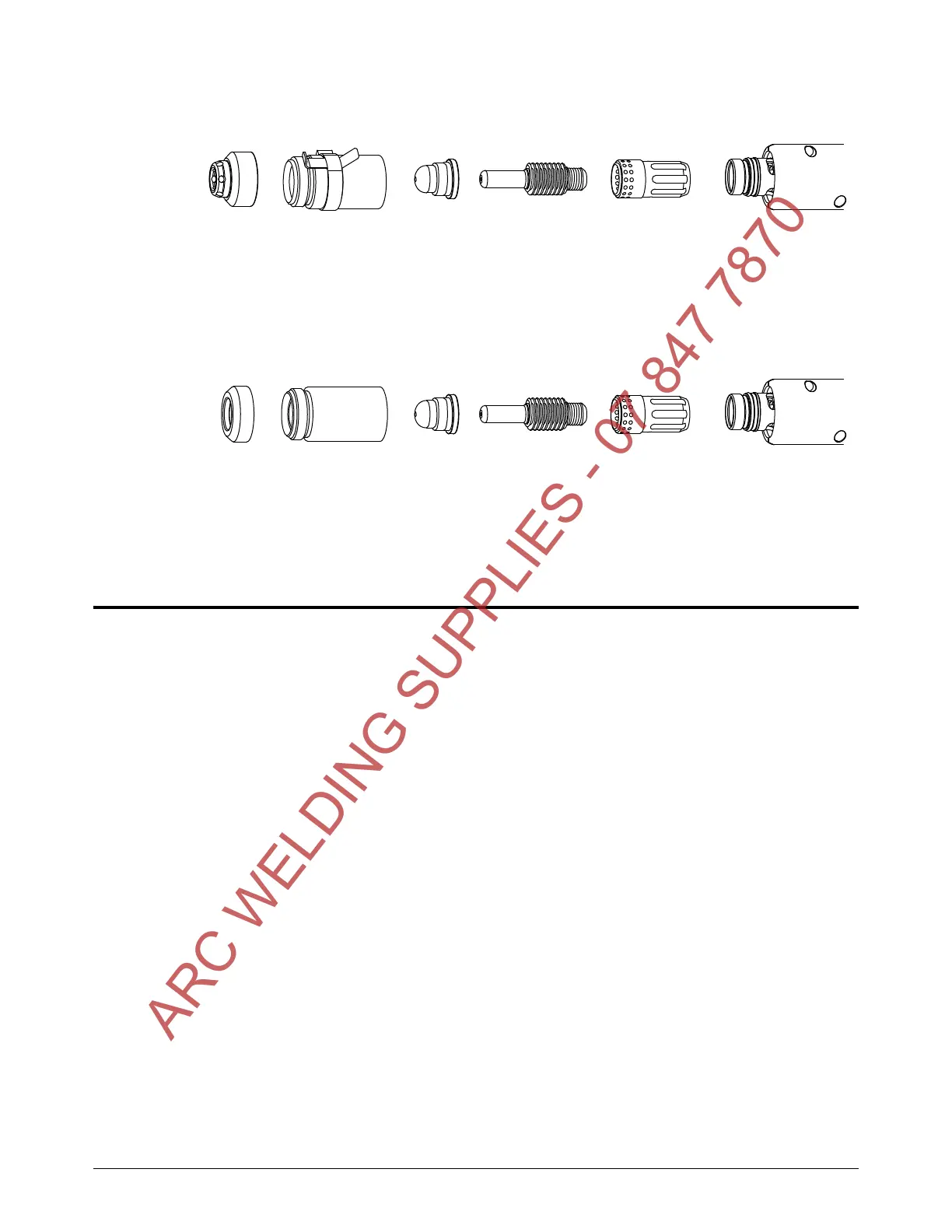

FineCut unshielded consumables

Consumable life

Many factors influence how often you need to change the consumables on your machine torch:

Poor gas supply quality

It is extremely important to maintain a clean, dry gas line. The presence of oil, water,

vapors, and other contaminants in the gas supply can degrade cut quality and

consumable life. See page 35 and page 39.

Cutting and gouging technique

Whenever possible, start cuts from the edge of the workpiece. This helps to extend the

life of the shield and the nozzle.

Maintain a proper pierce height. Refer to the cut charts starting on page 121.

Maintain a proper torch-to-work distance (standoff) when gouging. See page 80.

Shielded versus non-shielded consumables

Non-shielded consumables use a deflector instead of a shield. Non-shielded

consumables generally have a shorter life than shielded consumables.

Thickness of metal being cut

In general, the thicker the metal being cut, the more quickly the consumables become

worn. For best results, do not exceed the thickness specifications for this system. See

page 22.

See page 154 for guidelines on when to replace worn consumables.

220948

Shield

220953

Ohmic retaining

cap

220930

Nozzle

220857

Swirl ring

220842

Electrode

220955

Deflector

220854

Retaining cap

220930

Nozzle

220857

Swirl ring

220842

Electrode

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...