Installation and Setup

Powermax45 XP Operator Manual 809240 37

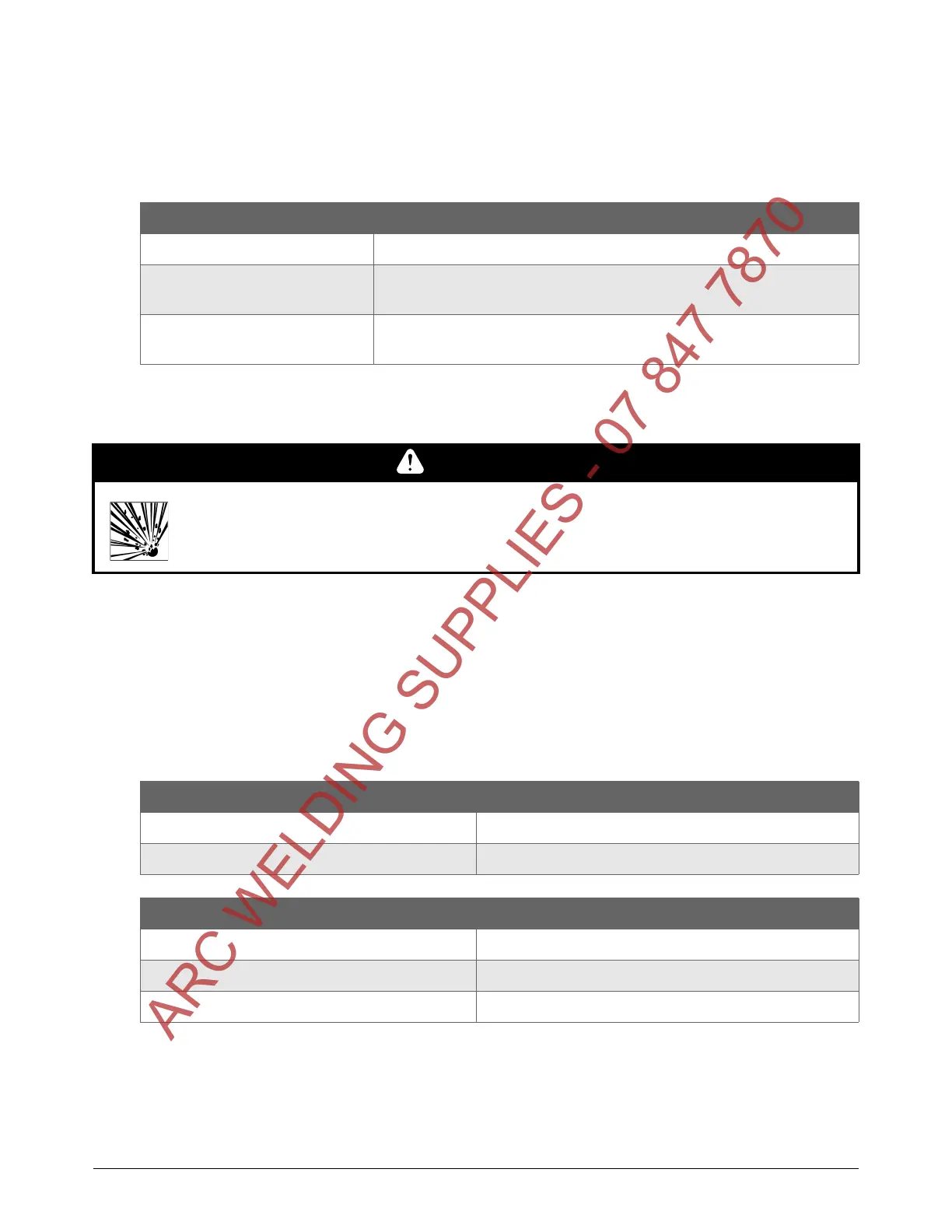

Gas flow rates

Refer to the cut charts starting on page 121 for flow rates specific to each cutting process

specified (based on the type of metal, the type of gas, and the output current).

Minimum inlet pressure (while gas is flowing)

The following pressure specifications apply for air, nitrogen, F5, and argon. Never exceed an inlet

gas supply pressure of 9.3 bar (135 psi).

You may need to adjust these pressures based on the equipment and conditions specific to your

environment. For example, additional gas filtration installed between the gas supply and the plasma

power supply may increase the required minimum inlet pressure. Consult the filter manufacturer.

Cutting

Process Gas flow rate

Cutting 188.8 slpm (400 scfh) at a minimum 5.9 bar (85 psi)

Maximum control gouging

(26 – 45 A)

165.2 slpm (350 scfh) at a minimum 4.1 bar (60 psi)

Precision gouging / marking

(10 – 25 A)

165.2 slpm (350 scfh) at a minimum 3.8 bar (55 psi)

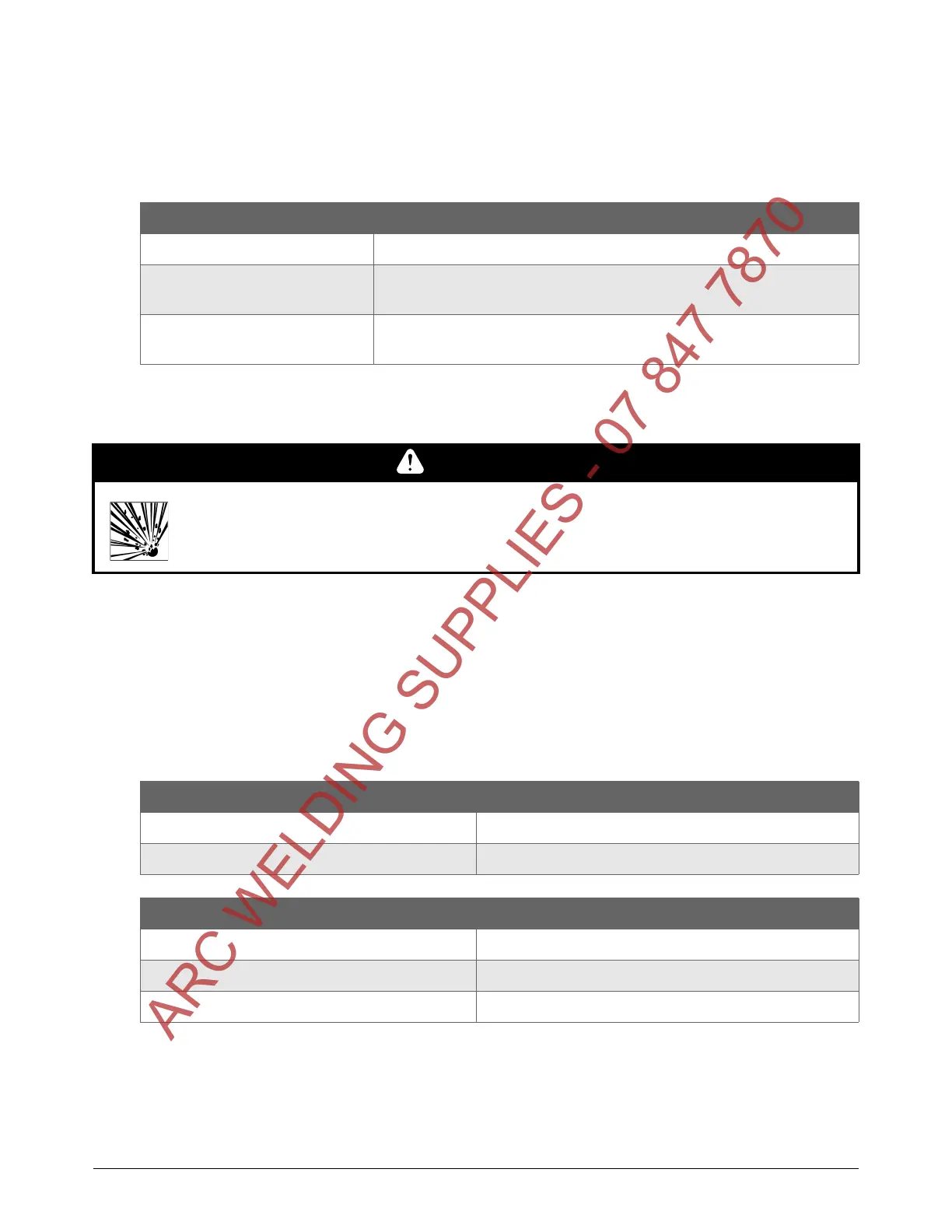

WARNING

The filter bowl in the power supply may explode if the gas pressure exceeds 9.3 bar

(135 psi).

Torch lead length – hand torches Minimum inlet pressure

6.1m (20feet) 5.5bar (80psi)

15 m (50 feet) 5.9bar (80psi)

Torch lead length – machine torches Minimum inlet pressure

7.6m(25feet) 5.5bar (80psi)

11 m (35 feet) 5.5bar (80psi)

15 m (50 feet) 5.9 bar (85 psi)

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...