Routine Maintenance

154 809240 Operator Manual Powermax45 XP

Inspect the consumables

The best way to judge the condition of used consumables is to regularly check the cut edge quality

of the metal. When the cut quality begins to deteriorate, inspect the consumables.

Many common cut issues can be resolved by installing new consumables in the torch. See page 46.

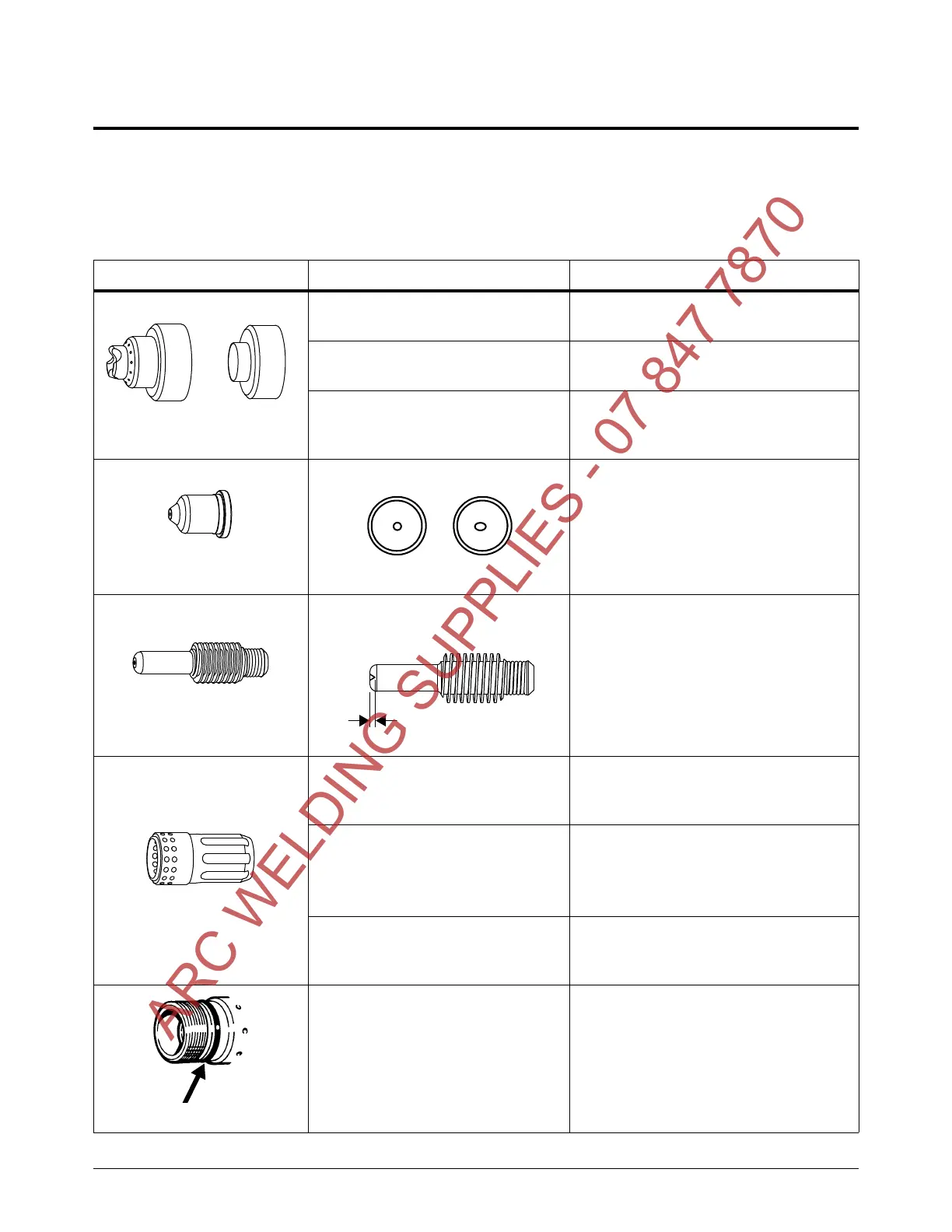

Part Inspect Action

Shield

Deflector

Shield: The center hole for

roundness.

Shield: Replace the shield if the center

hole is no longer round.

Deflector: The edges of the center

hole for damage or noticeable wear.

Deflector: Replace the deflector is the

center hole is worn or damaged.

The gap between the nozzle and the

shield or deflector for accumulated

debris.

Remove the shield or deflector and clean

away any debris.

Nozzle

The center hole for roundness. Replace the nozzle if the center hole is

not round.

Replace the nozzle and the electrode

together.

Electrode

The center surface for wear, and

verify the pit depth.

Replace the electrode if the surface is

severely worn or the pit depth is greater

than 1.6 mm (1/16 inch) deep.

Replace the nozzle and the electrode

together.

Swirl ring

The surface inside the swirl ring for

damage or wear and the gas holes

for blockages.

Replace the swirl ring if the surface is

damaged or worn or any of the gas holes

are blocked.

The O-ring inside the swirl ring for

damage or wear.

If the O-ring in the swirl ring is cracked,

worn, or damaged, replace the swirl ring.

Do not apply grease or other lubricants

to the O-ring in the swirl ring.

The length of the swirl ring. If the length of the 220857 or 220947

swirl ring is less than 30.5 mm

(1.2 inches), replace it.

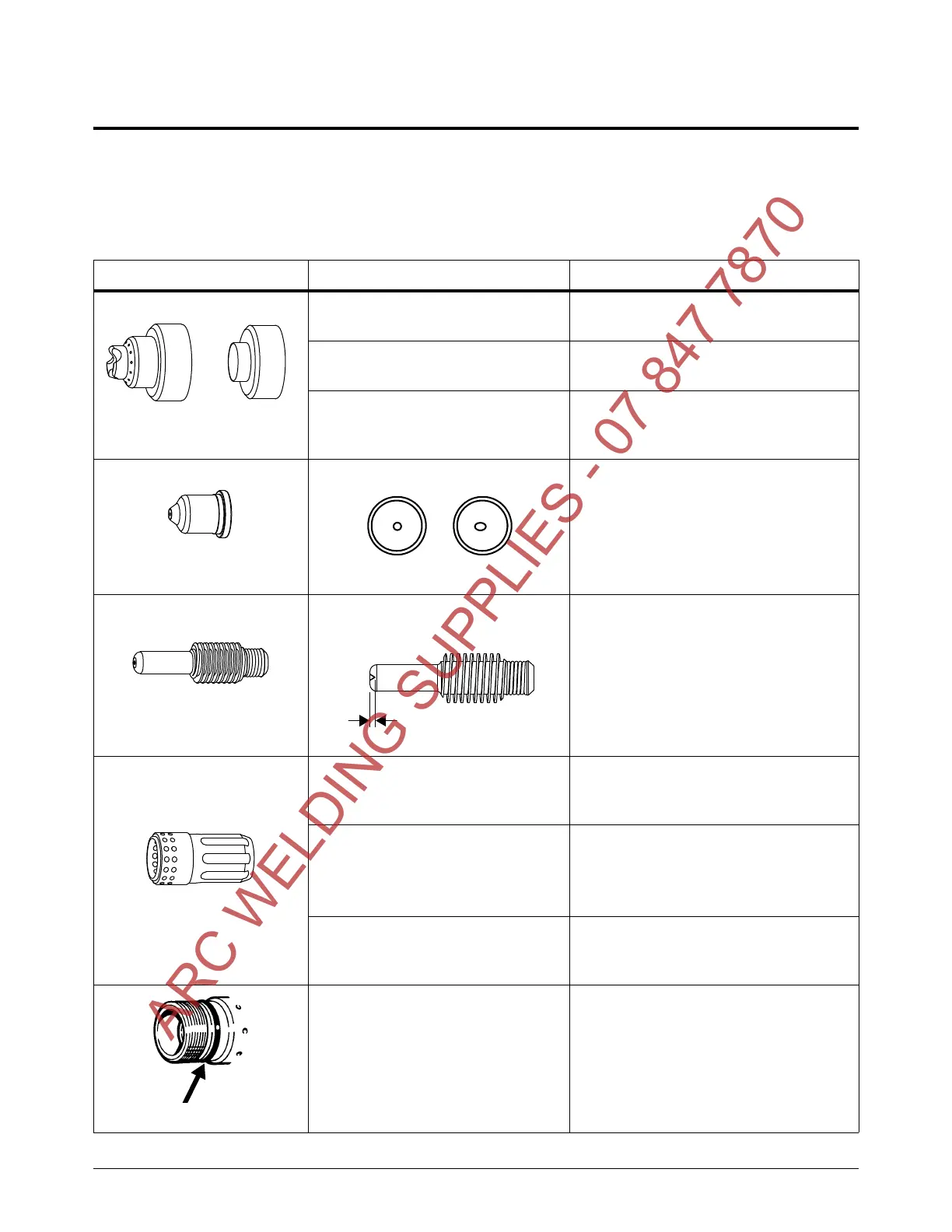

Torch O -ri ng

The surface for damage, wear, or a

lack of lubrication.

If the torch O-ring is dry, apply a thin film

of silicone lubricant on the O-ring and

the threads. The O-ring should look

shiny, but there should not be any excess

or built-up lubricant.

If the O-ring is cracked or worn, replace

it.

Maximum 1.6 mm

(1/16 inch)

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...