Gouge with the Hand Torch and Machine Torch

Powermax45 XP Operator Manual 809240 79

6. Make sure you have gouged

completely through the top layer. Pull

the metal plates apart.

7. Use the same gouging process to

remove the spot weld that remains on

the bottom plate.

To avoid damaging the

bottom plate, you may want

to turn down the output

current to 10 A. Increase the

current if needed based on

the thickness of the metal.

Hold the torch at a 40° – 45°

angle. Slightly adjust the

angle of the torch as needed based on the thickness of the metal.

Stretch the arc to approximately 10 – 11 mm (3/8 – 1/2 inch) as you gouge.

Use very short strokes in a back-and-forth weaving motion until you have removed the

spot weld.

Some scraping or grinding may be required to completely remove all

remnants of the spot weld from the bottom plate.

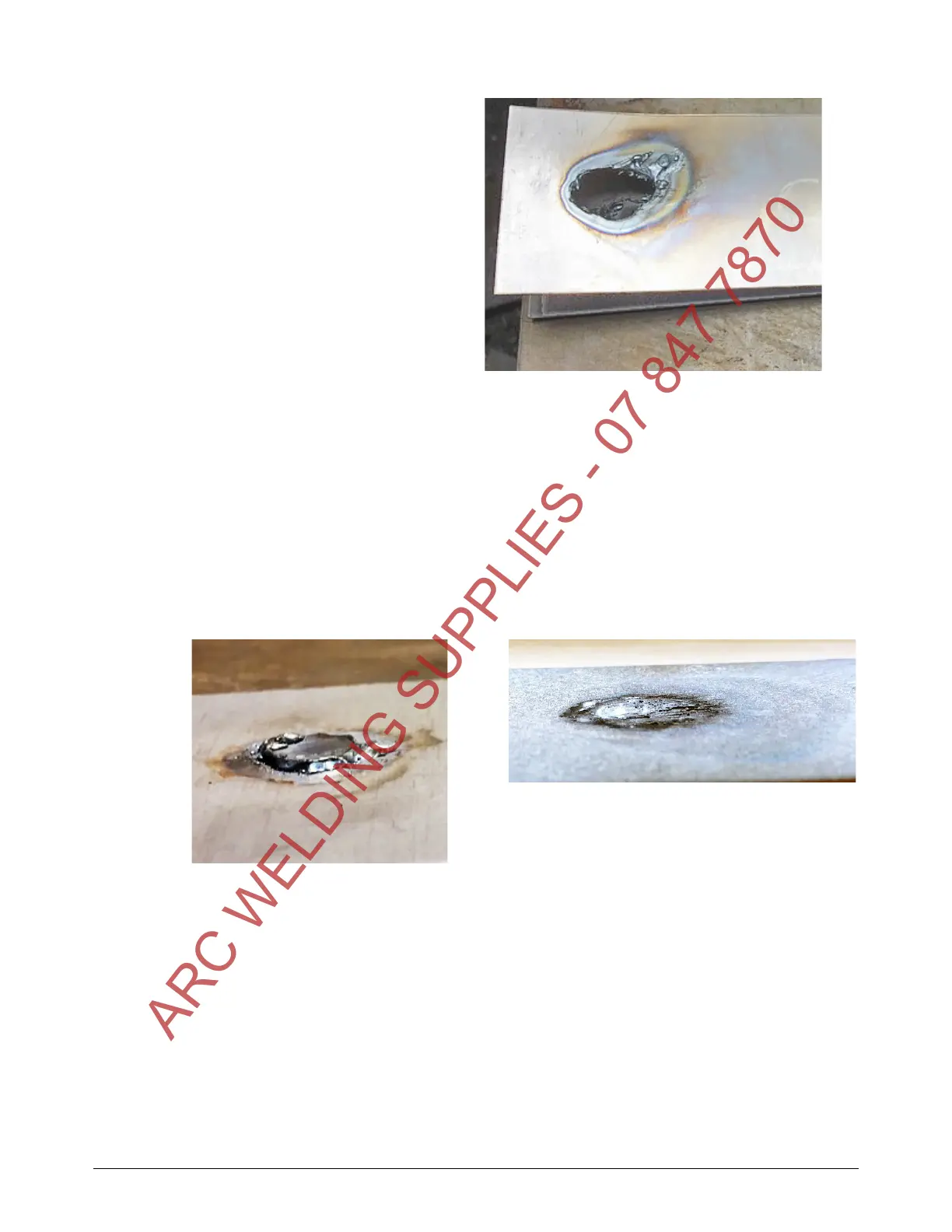

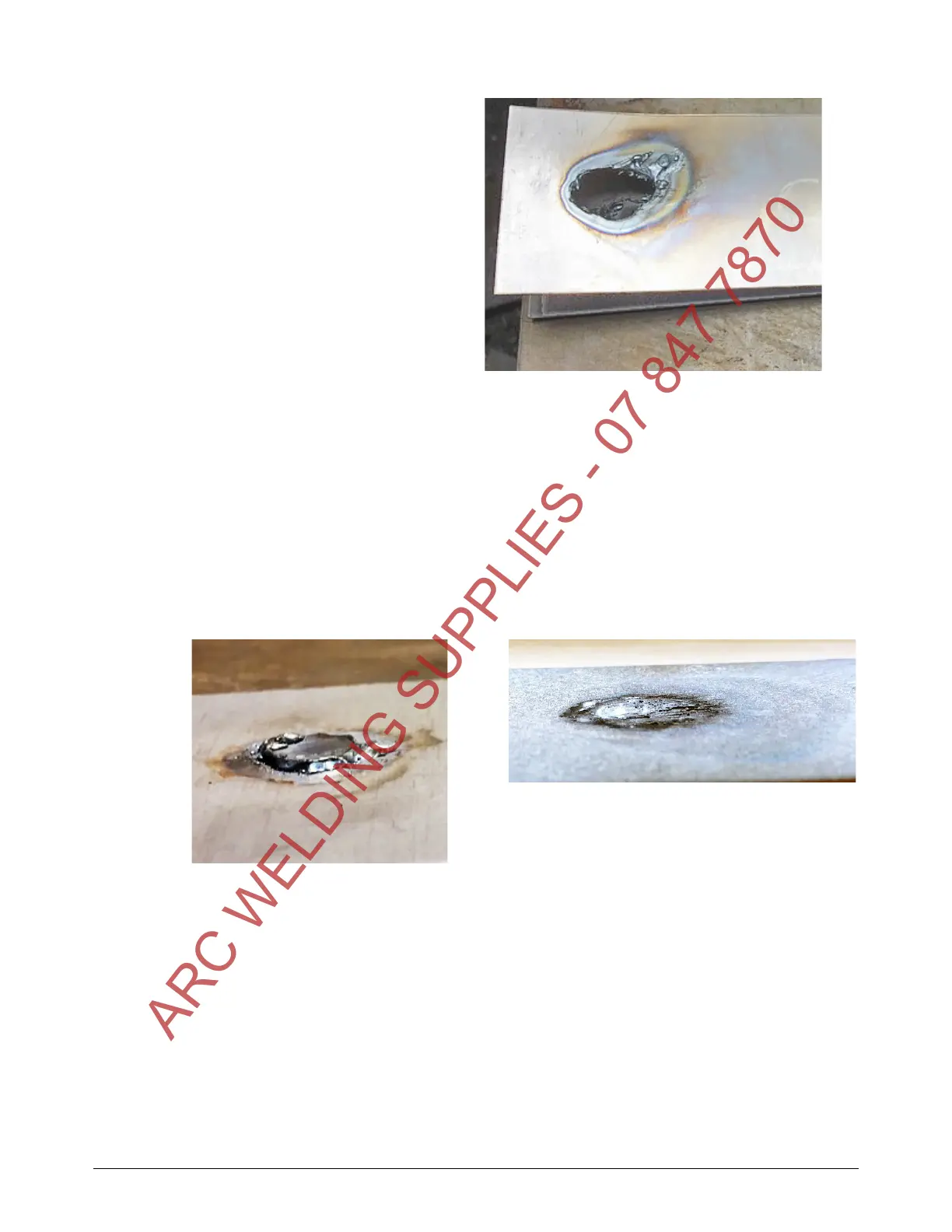

Spot weld on bottom plate Spot weld removed

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...