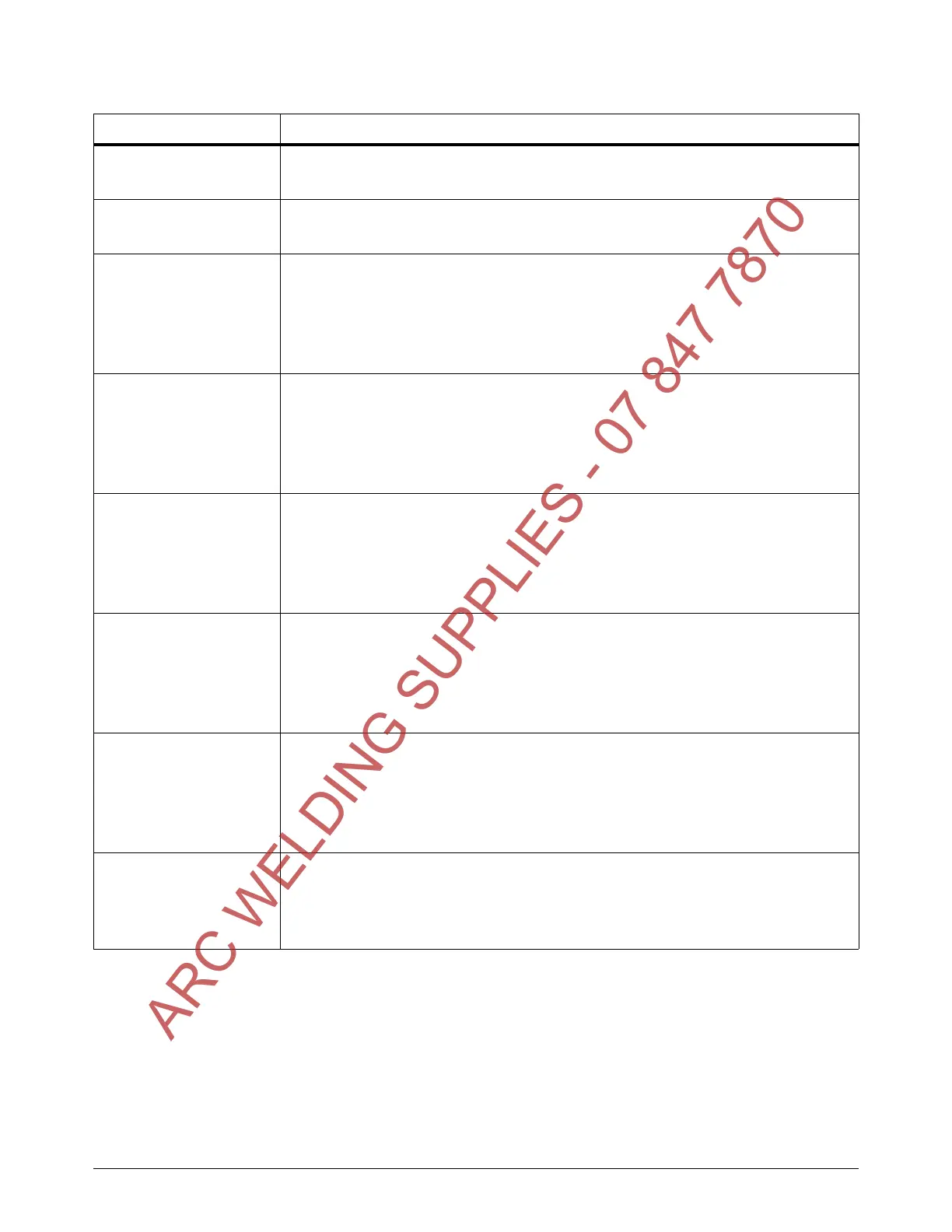

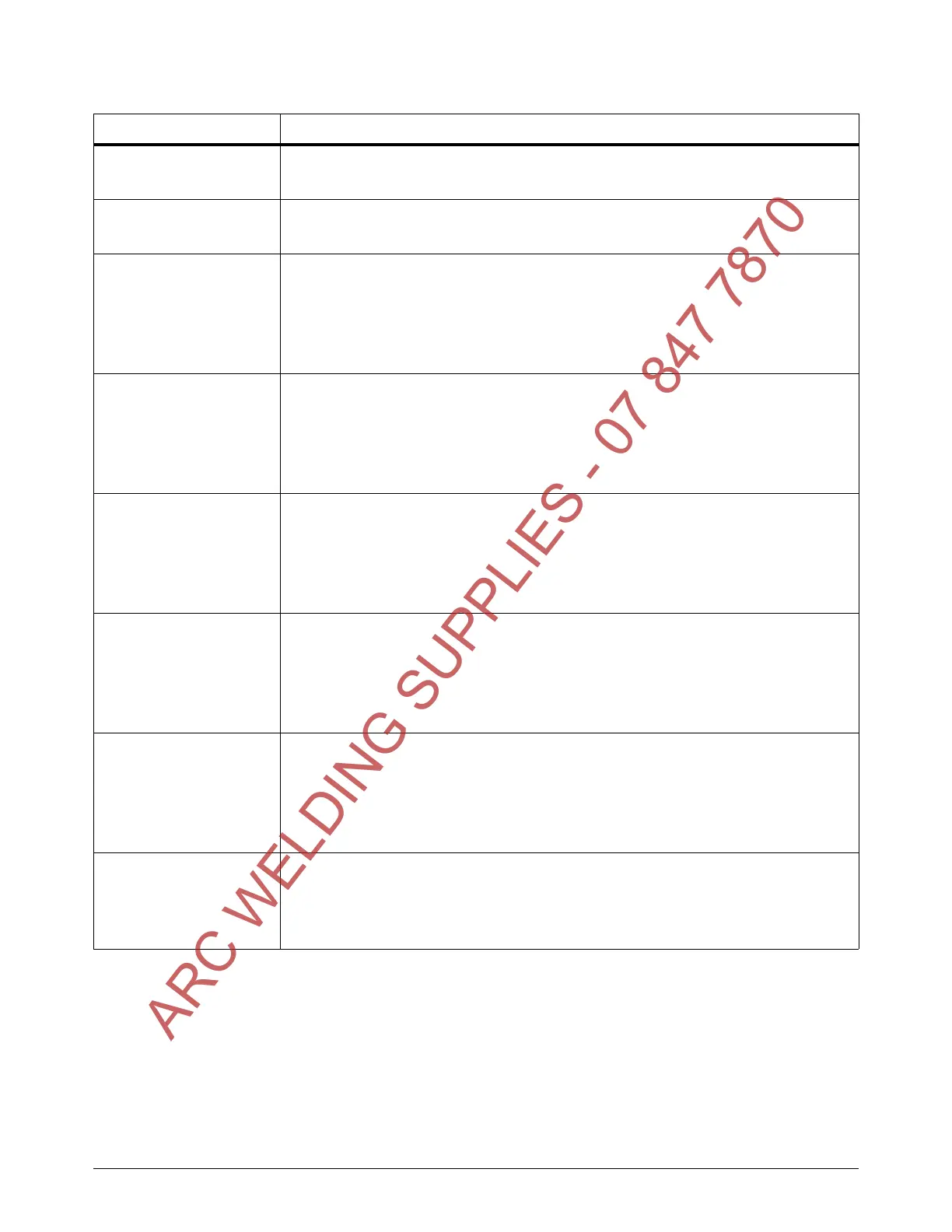

Gouge with the Hand Torch and Machine Torch

Powermax45 XP Operator Manual 809240 85

Problem Solution

The arc goes out during

gouging.

• Decrease the arc stretch (standoff).

• Increase the angle of the torch to the workpiece.

The torch tip bumps into

slag.

• Increase the arc stretch (standoff).

• Keep the torch tip pointed in the direction of the gouge you want to create.

The gouge is too deep. • Decrease the angle of the torch to the workpiece.

• Increase the arc stretch (standoff).

• Increase the gouging speed.

• Decrease the output current. Do not set the output current below 26 A if you are

using the Maximum Control gouging consumables.

The gouge is too shallow. • Increase the angle of the torch to the workpiece.

• Decrease the arc stretch (standoff).

• Decrease the gouging speed.

• Increase the output current. Do not set the output current above 25 A if you are

using the Precision gouging consumables.

The gouge is too wide. • Increase the angle of the torch to the workpiece.

• Decrease the arc stretch (standoff).

• Increase the gouging speed.

• Decrease the output current. Do not set the output current below 26 A if you are

using the Maximum Control gouging consumables.

The gouge is too narrow. • Decrease the angle of the torch to the workpiece.

• Increase the arc stretch (standoff).

• Decrease the gouging speed.

• Increase output current. Do not set the output current above 25 A if you are using

the Precision gouging consumables.

When removing a spot

weld, the arc pierces the

bottom metal plate.

• Decrease the output current (amperage).

• Make sure the Precision gouging consumables are installed.

• Maintain a steady gouging speed and gouge only until the bottom metal plate is

visible.

• Increase the arc stretch to approximately 10 – 11 mm (3/8 – 1/2 inch).

The spot weld is not

visible while gouging.

• Stretch the arc to approximately 10 – 11 mm (3/8 – 1/2 inch) for better visibility

of the spot weld.

• Make sure the Precision gouging consumables are installed.

• Make sure the output current is not set above 25 A.

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...