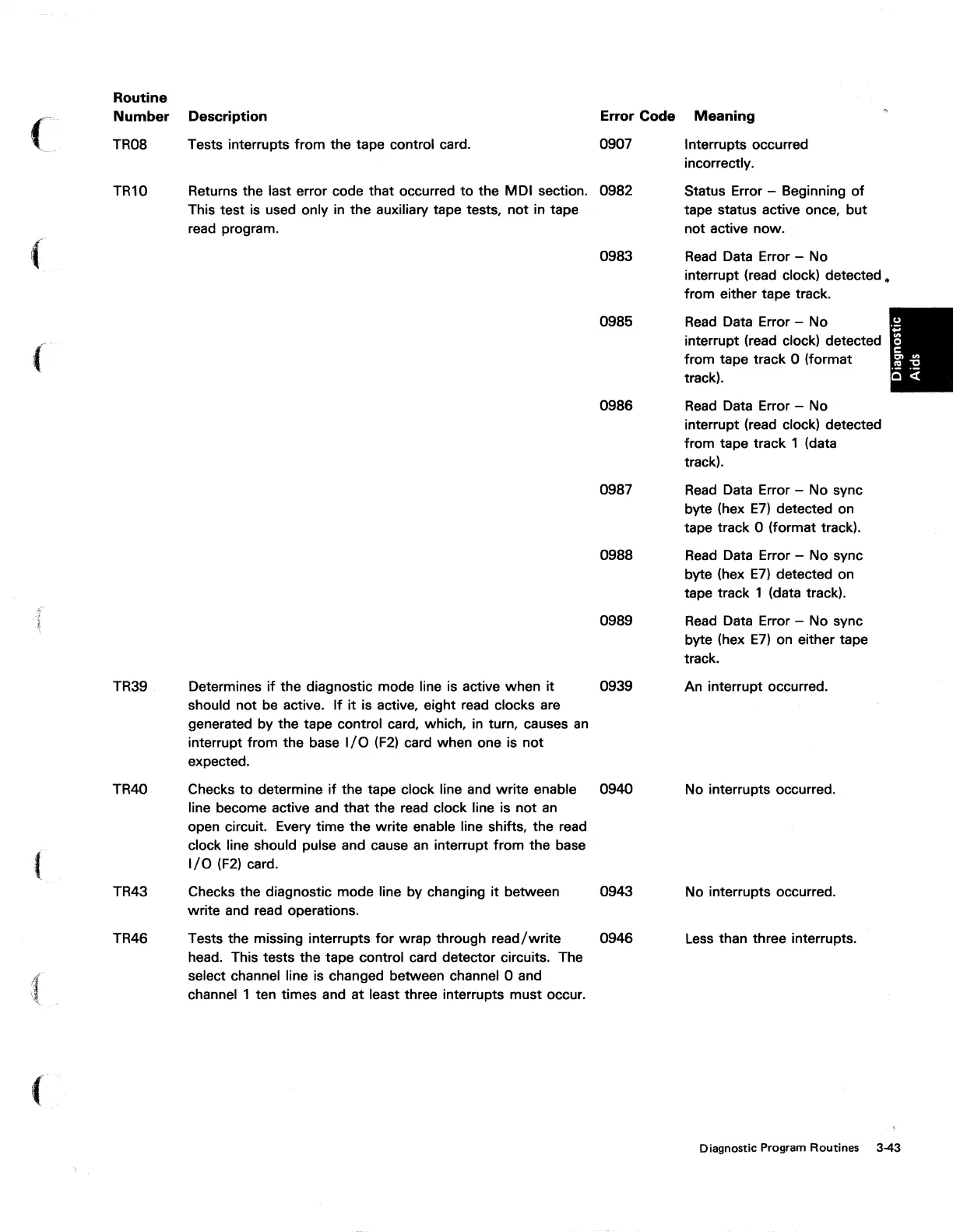

Routine

(~

Number

Description

Error

Code

Meaning

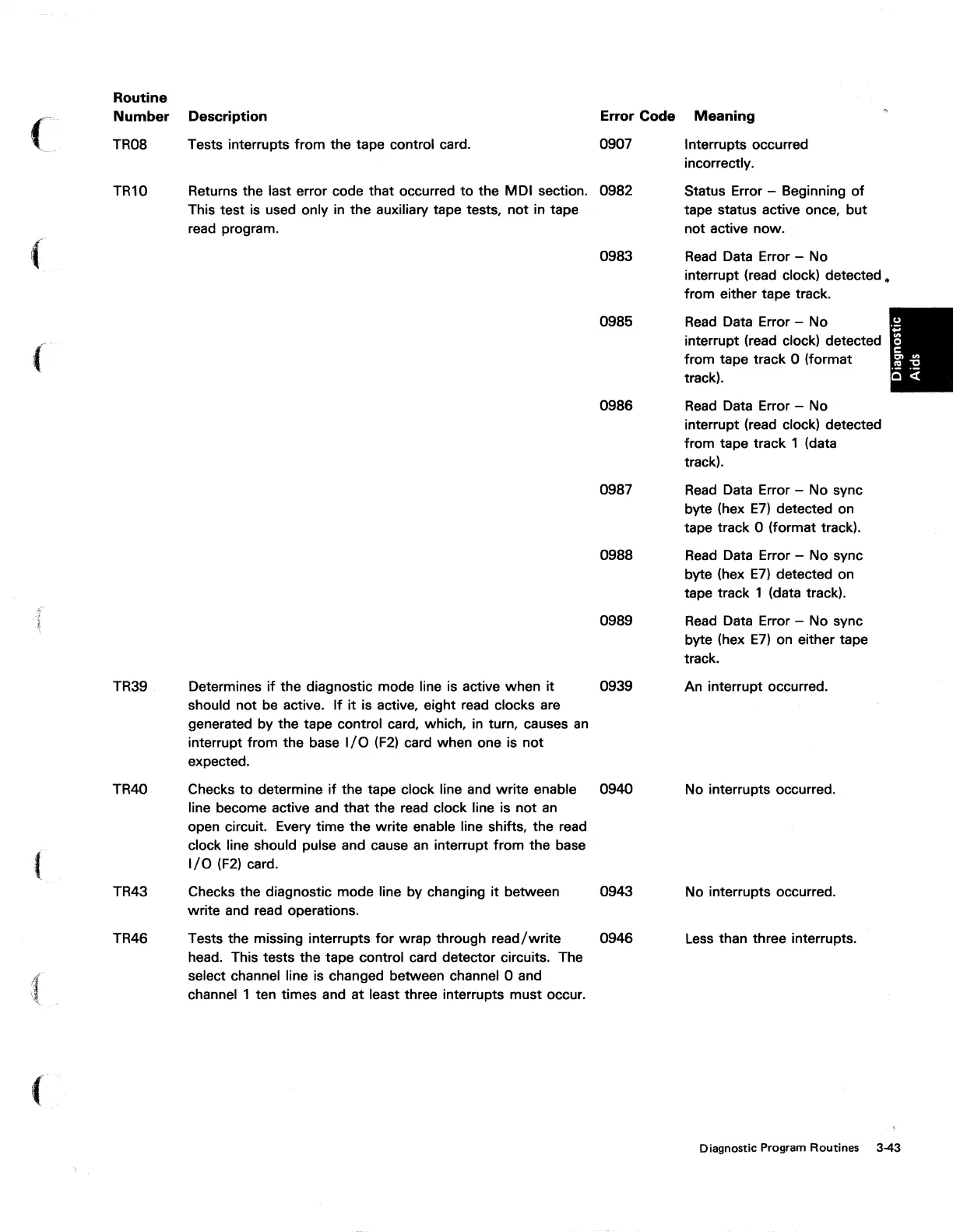

TR08

Tests interrupts

from

the tape control card. 0907

Interrupts occurred

incorrectly.

TR10 Returns the last error code that occurred

to

the

MOl

section.

0982

Status Error - Beginning

of

This test

is

used only

in

the auxiliary tape tests, not in tape tape status active once,

but

read program. not active now.

0983

Read

Data Error - No

interrupt (read clock)

detected.

from either tape track.

0985

Read

Data Error - No

(

interrupt (read clock) detected

from tape track 0 (format

track).

0986

Read

Data Error - No

interrupt (read clock) detected

from tape track 1 (data

track).

0987

Read

Data Error - No sync

byte (hex

E7)

detected on

tape track 0 (format track).

0988

Read

Data Error - No sync

byte (hex

E7)

detected on

tape track 1 (data track).

r

"

0989

Read

Dsta Error - No sync

byte (hex

E7)

on either tape

track.

TR39 Determines

if

the diagnostic mode line

is

active when it 0939

An interrupt occurred.

should not

be

active.

If

it

is active, eight read clocks are

generated by the tape control card, which,

in

turn, causes

an

interrupt from the base

I/O

(F2)

card when one is

not

expected.

TR40 Checks

to

determine

if

the tape clock line and write enable 0940 No interrupts occurred.

line become active and

that

the read clock line is not

an

open circuit. Every time the write enable line shifts, the read

(

clock line should pulse and cause

an

interrupt from the base

I/O

(F2)

card.

TR43

Checks the diagnostic mode line by changing it between 0943

No interrupts occurred.

write and read operations.

TR46 Tests the missing interrupts

for

wrap through

read/write

0946

Less

than three interrupts.

head. This tests the tape control card detector circuits. The

(

select channel line

is

changed between channel 0 and

channel 1 ten times and

at

least three interrupts must occur.

(

Diagnostic Program

Routines

343

Loading...

Loading...