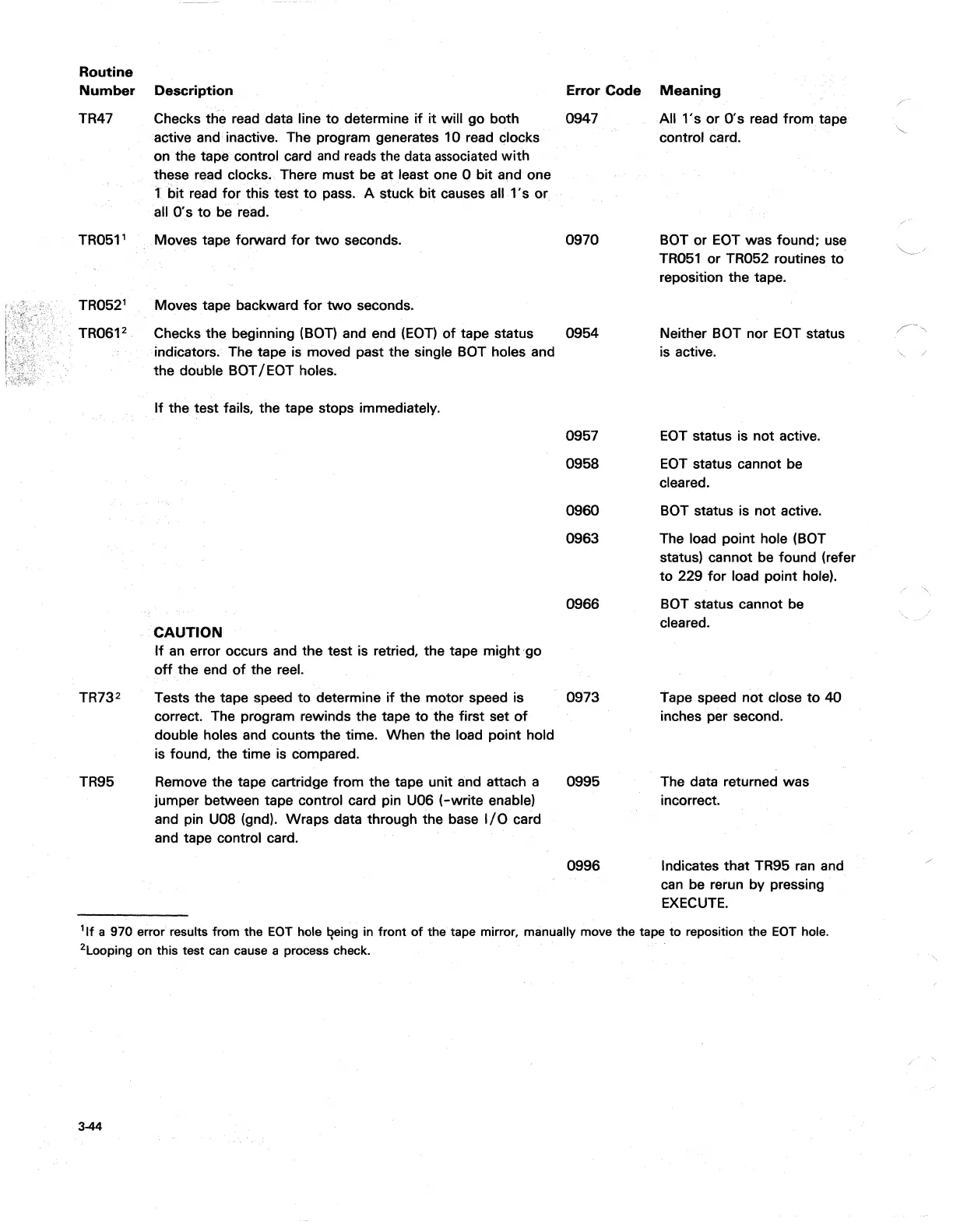

Routine

Number Description

E"or

Code

Meaning

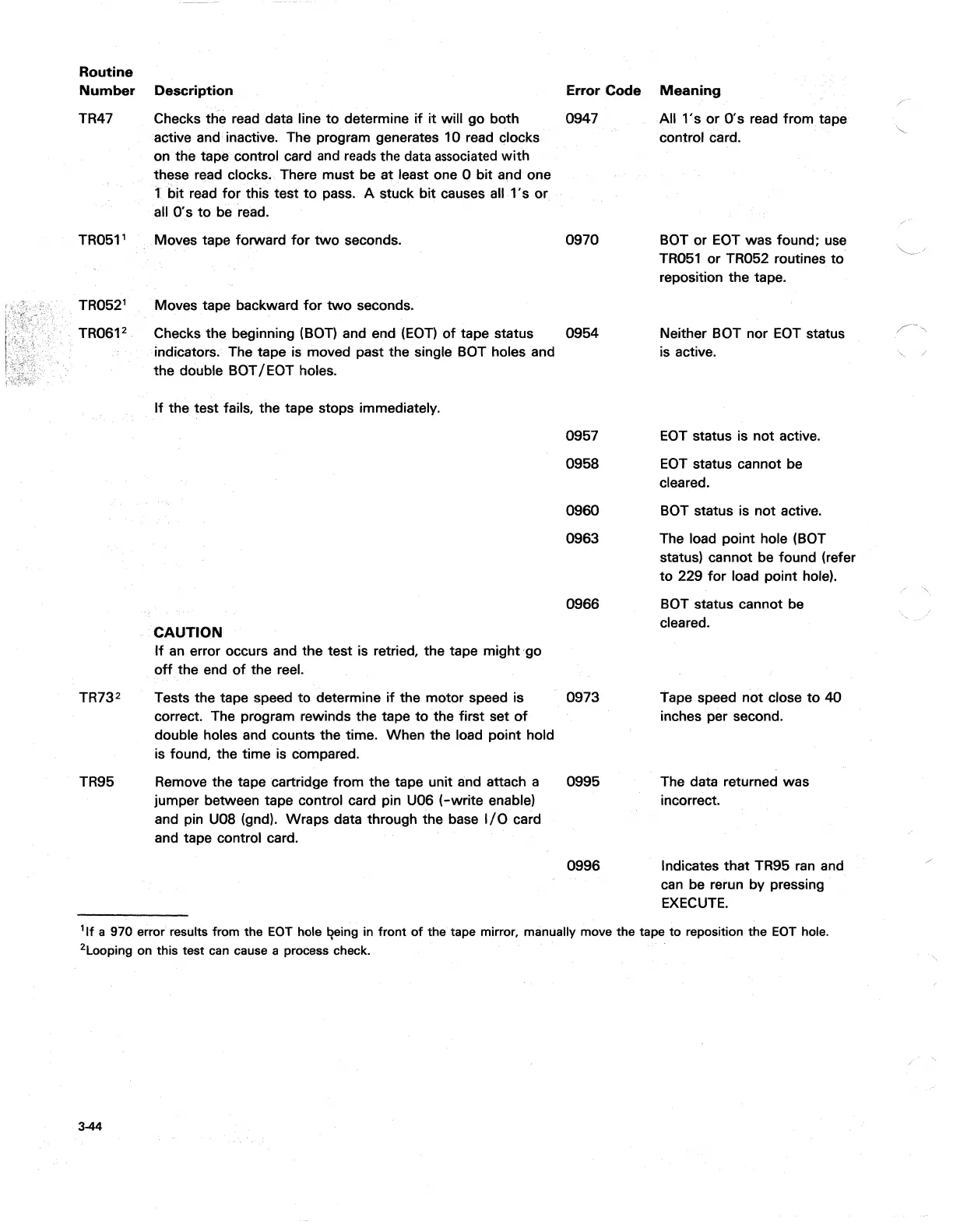

TR47 Checks the read data line

to

determine

if

it

will go both 0947 All 1's or

O's

read from tape

-active and inactive. The program generates 10 read clocks control card.

on the tape cOhtrol card

and

reads

the data

associated

with

th~se

read clocks

..

There must be

at

least one 0 bit and one

t bit read

for

this test

to

pass. A stuck

bit

causes

all1's

or.

all

O's

to

be

'read.

TR051

1

Moves tape forward

for

two

seconds. 0970 BOT or

EaT

was found;

use

TR051 or TR052 routines

to

reposition the tape.

TR052

1

Moves tape backward

for

two

seconds.

TR06P,

Checks the beginning (BOT) and end

(EOn

of

tape status

0954 Neither BOT nor

EaT

status

indicators. The tape is moved past the single BOT holes and is active.

the double

BOT/EaT

holes.

If

the test fails, the tape stops immediately.

0957

EaT

status is

not

active.

0958

EaT

status cannot be

cleared.

0960 BOT status is

not

active.

0963

The load point hole (BOT

status) cannot be found (refer

to

229

for

load point hole).

0966

BOT status cannot be

CAUTION

cleared.

If

an

error occurs and the test is retried, the tape might 'go

off

the end

of

the reel.

TR73

2

Tests the tape speed

to

determine

if

the motor speed is 0973 Tape speed

not

close

to

40

correct. The program rewinds the tape

to

the first set

of

inches per second.

double holes and counts the time. When the load point hold

is found, the time is compared.

TR95 Remove the tape cartridge from the tape unit and attach a

0995 The data returned was

jumper between tape control card pin U06

(-write

enable) incorrect.

and pin U08 (gnd). Wraps data through the base

I/O

card

and tape control card.

0996

Indicates

that

TR95

ran

and

can

be rerun by pressing

EXECUTE.

'If

a

970

error

results

from

the

EOT

hole

t?eing

in

front of

the

tape

mirror,

manually

move

the

tape

to reposition

the

EOT

hole.

2Looping

on

this test

can

cause

a

process

check.

3-44

/--

"'--

"'--_/

~~"

'.

/

-"

,

Loading...

Loading...