Multitron - Incubation Shaker

Options

Page 38 of 146 25 February 2019

4.2 Direct Steam Humidification

Part of the medium can evaporate, in particular in case of small

volumes of work (e.g. when using microtitre and deep well plates)

and long cultivation processes. To reduce evaporation, the equip-

ment can be fitted with a direct steam humidification. This regu-

lates the humidity in the incubation chamber to a defined setpoint

and thus ensures a consistent culture volume.

4.2.1 Setup and Function

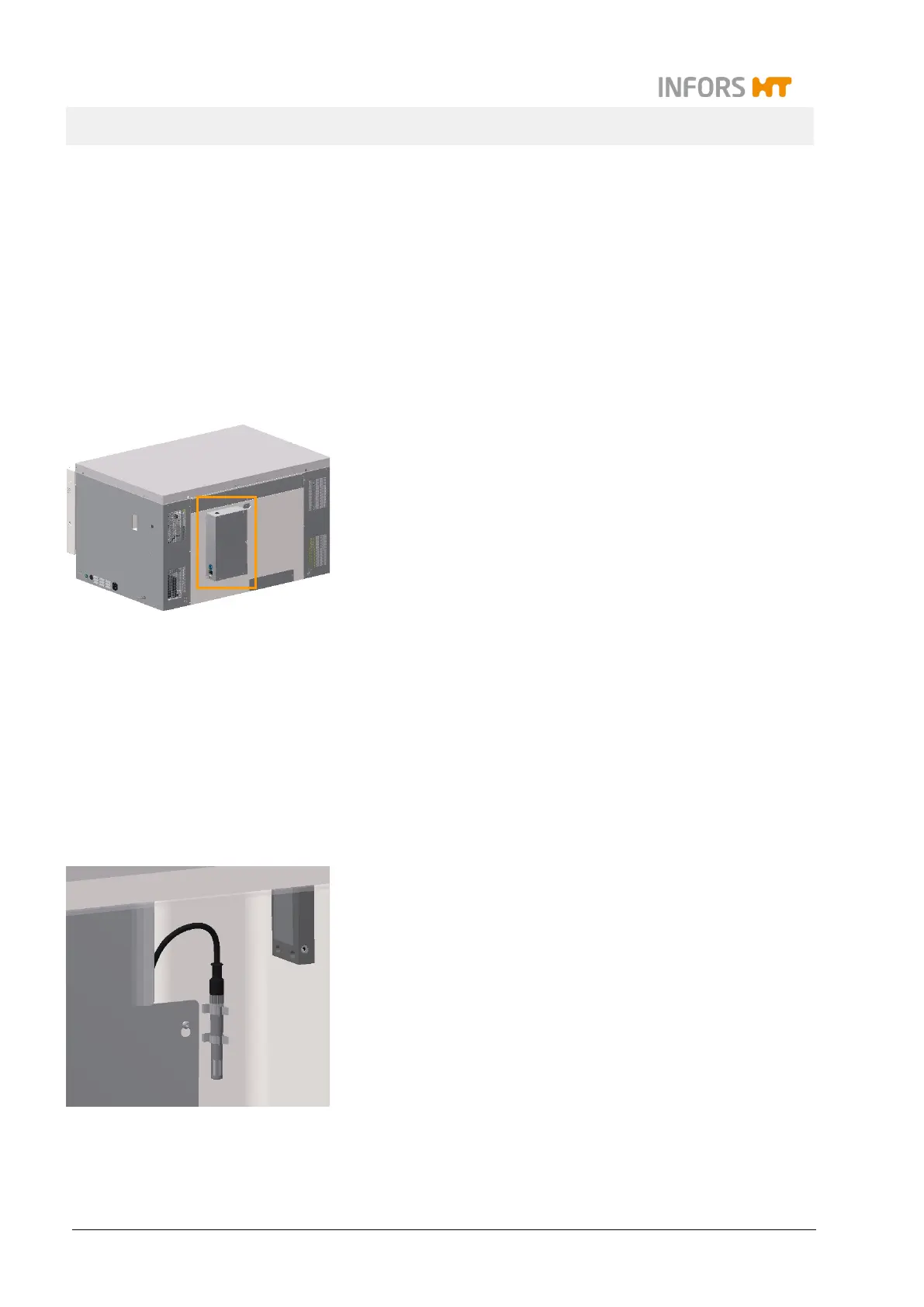

The direct steam humidification is mounted on the rear of the cas-

ing.

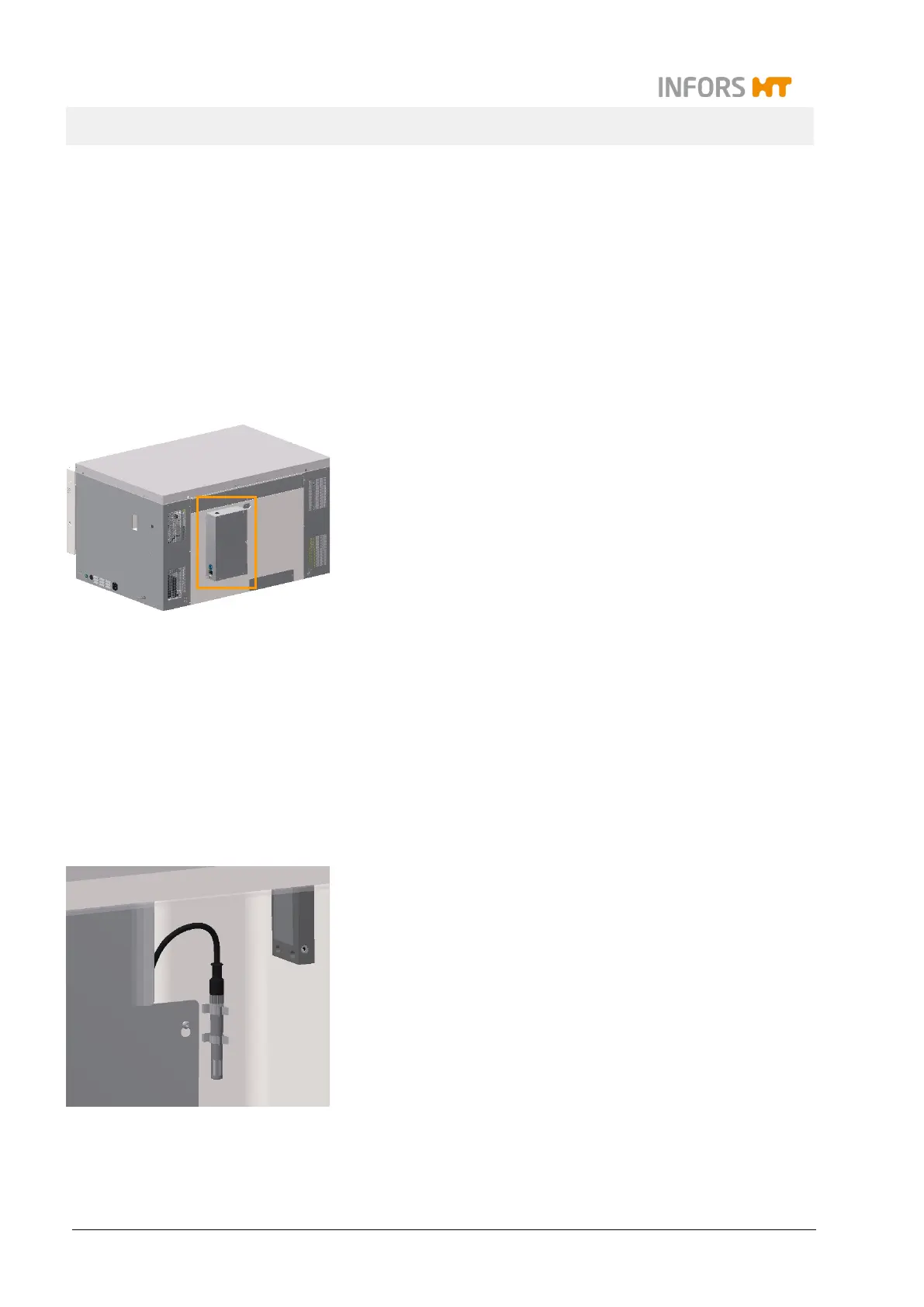

A controlled pump feeds water dropwise into an evaporator cham-

ber via a feed hose. The water evaporates and is then fed into the

incubation chamber.

There are two possibilities to supply the water:

Unpressurised from a water tank

From a pressurised pipe with inlet pressure of max. 0.3 bar

To prevent condensation inside the equipment, the equipment fea-

tures several heating elements (door heating, door seal heating

and floor heating). These are activated automatically, as soon as

the direct steam humidification is switched on.

For an equipment without cooling on top, the equipment is addi-

tionally equipped with a cover (H = 40 mm) to reduce conde

on the ceiling.

The humidity in the incubation chamber is measured and regulated

using a humidity sensor. This is located in the rear wall of the incu-

bation chamber.

Loading...

Loading...