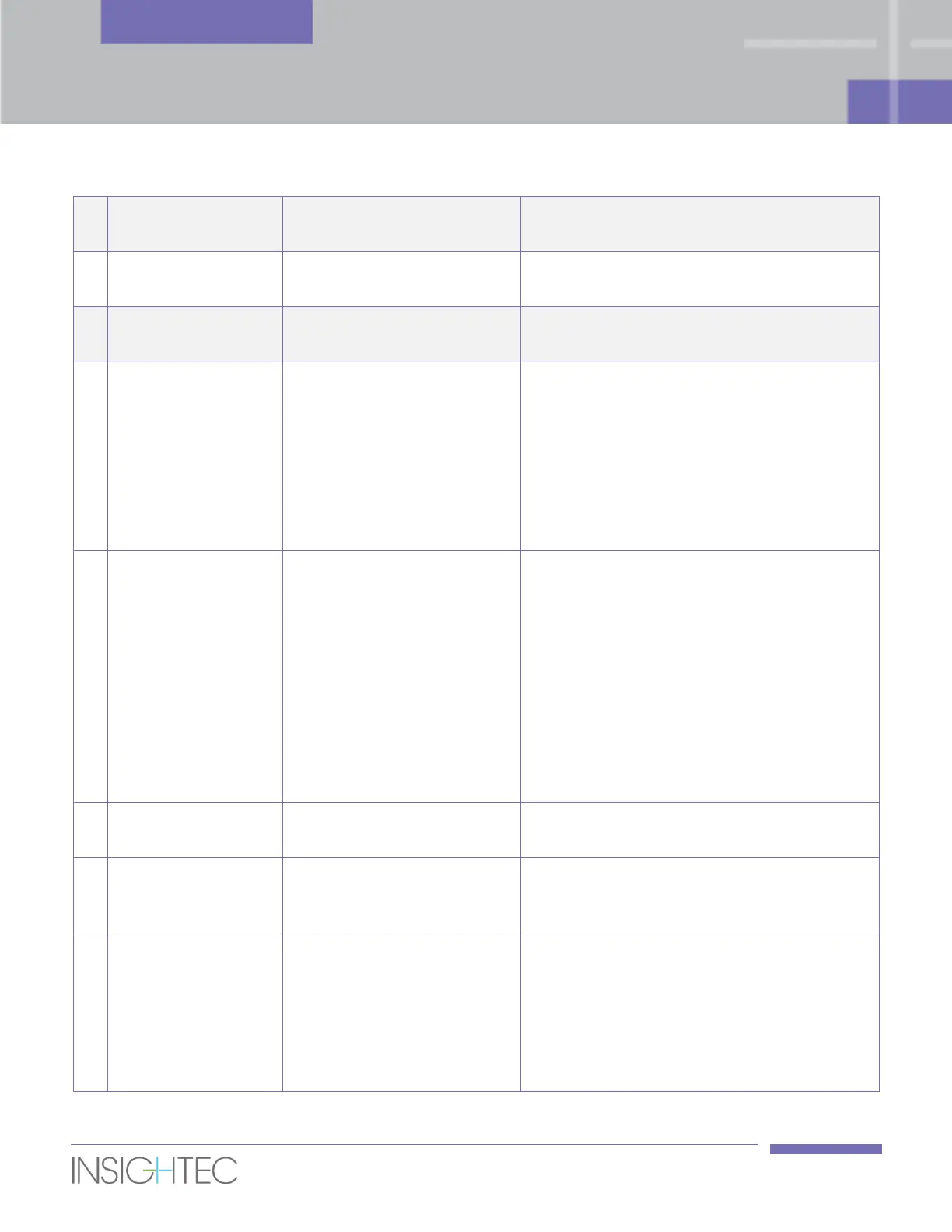

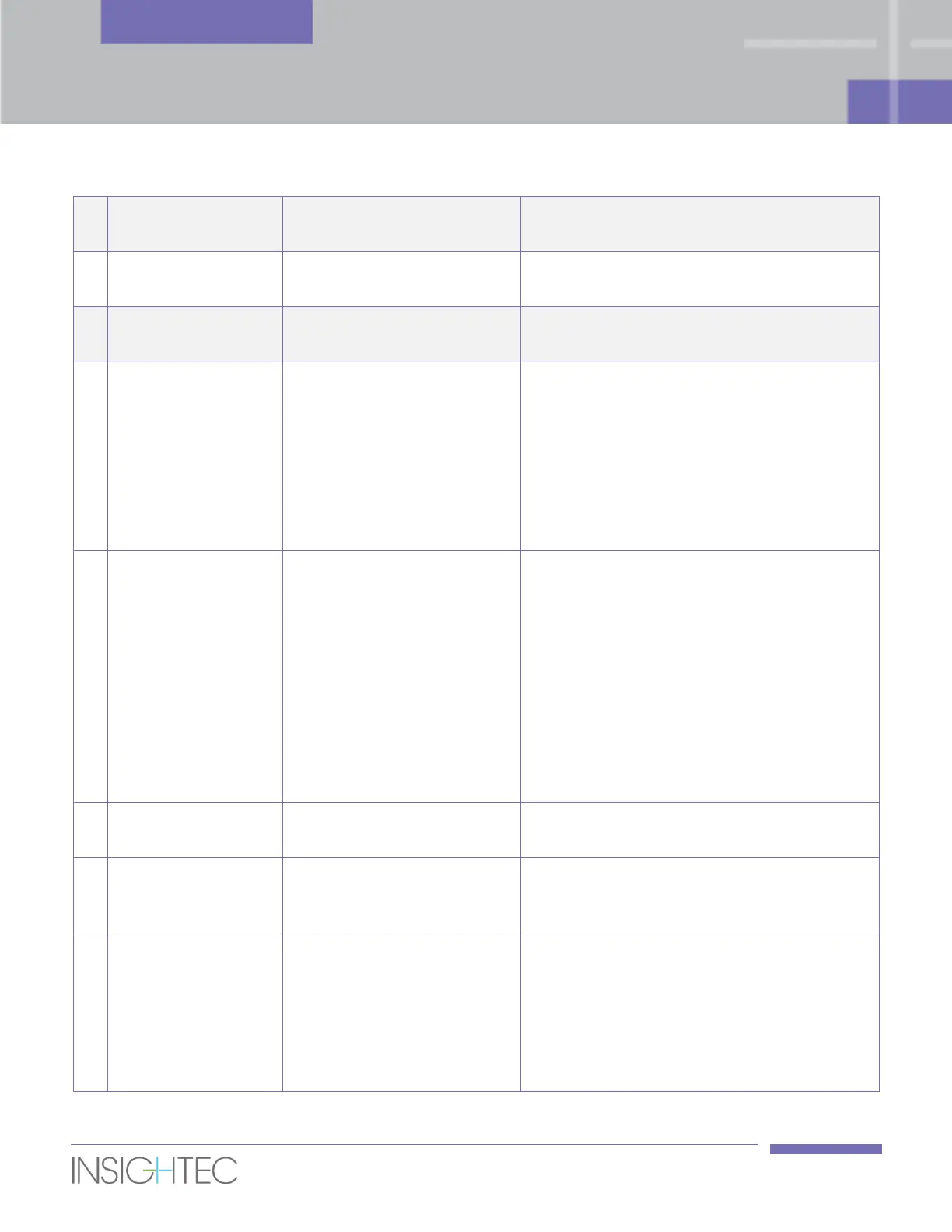

WATER SYSTEM MAINTENANCE

Manual Part Number

condensation, circulate water in warming

state for ~5 min.

The water pressure in the

balloon is too high.

Drain 30 CC from the balloon, and more if the

error persists (up to reference volume).

The water pressure in the

balloon is too low.

Fill 30 CC into the balloon, and more if the

error persists.

The flow rate of the

circulating water is above

threshold.

◼ Check visually for bubbles in the

balloon/hoses, the error might occur as

long as there are bubbles in the system.

◼ If it occurs during transducer preparation

ignore it by pressing <Mute> on remote

control.

◼ Check for water leaks.

The flow rate of the

circulating water is below

threshold.

◼ Check visually for bubbles in the

balloon/hoses, the error might occur as

long as there are bubbles in the system.

◼ If it occurs during transducer preparation

ignore it by pressing <Mute> on remote

control.

◼ Check for water leaks.

◼ Check water filter on the table.

◼ Check for bend/ pinched hoses.

General error, as a result of

several errors at once.

◼ Click “Reset” on the control panel.

The water temperature of

the chiller is not within

boundaries.

◼ Check temperature reading on chiller

display (in equipment room).

The system diagnosed that

there is coolant level drop

inside the chiller coolant tank

(in equipment room).

◼ Check for coolant leaks around the table

and along the hoses up to the chiller (in

equipment room).

◼ Coolant may evaporate. Add coolant to

the chiller according to the level signs (in

equipment room).

Loading...

Loading...