8 Commissioning/Shutdown

102 of 212

PumpDrive 2

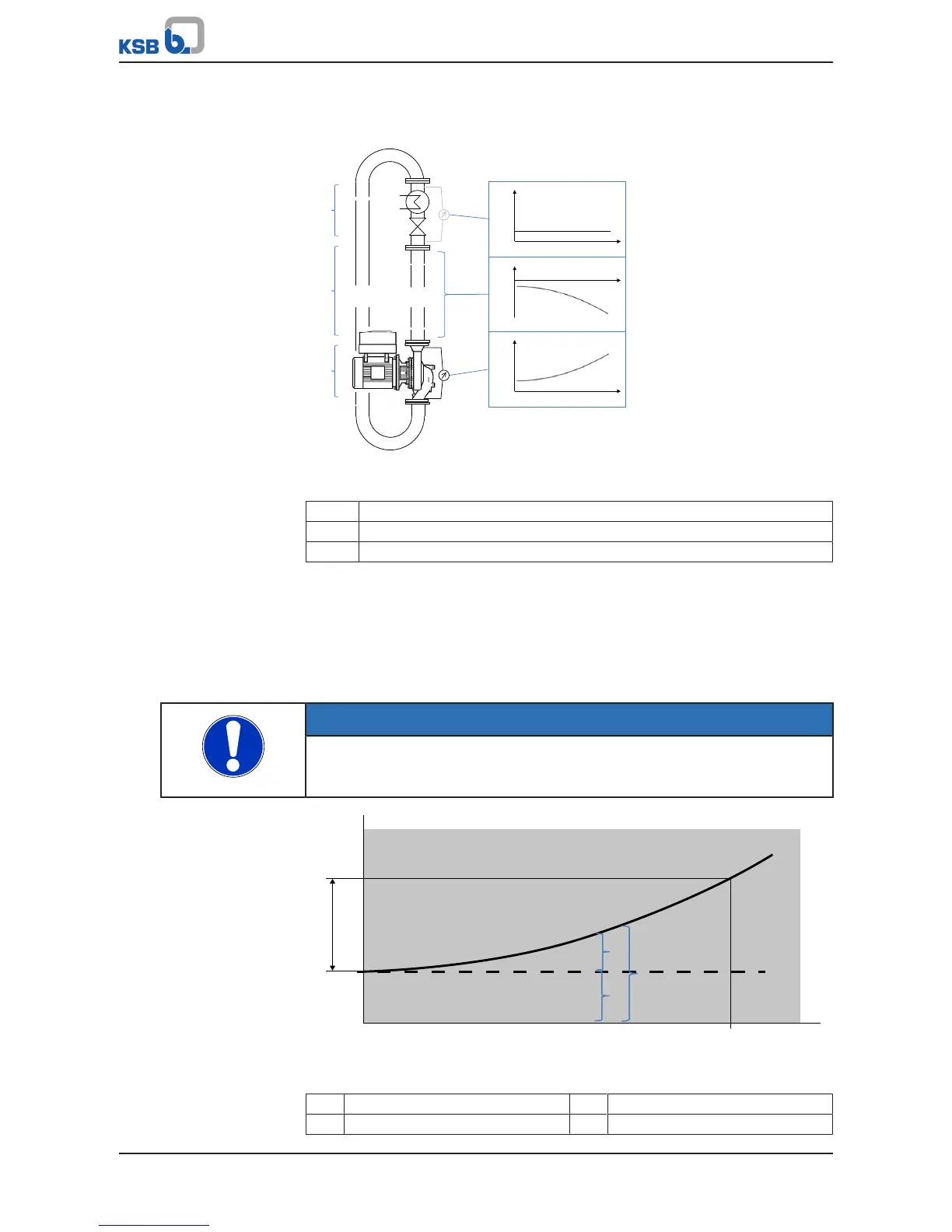

Sensorless differential pressure control with dynamic pressure compensation

(Sensorless Dyn Press Comp)

Fig.72: Differential pressure control with dynamic pressure compensation in closed

system

1 Pump set with diagram of flow rate-dependent setpoint

2 Piping with diagram of pressure losses

3 Consumer with differential pressure diagram

In a closed hydraulic system, an almost constant differential pressure can be achieved

at the consumer through sensorless dynamic pressure compensation, without the

need for pressure sensors. The method is based on the characteristic curves of the

pump. Steep power curves are conducive to high process accuracy. The process is

suitable to a limited extent if sections of the power curve are constant over the flow

rate. It is activated by setting the Type of Control parameter (3-6-1) to Differential

Pressure (Sensorless) and setting the Dynamic Pressure Compensation Method

(3-9-3-1) to Flow Rate.

NOTE

Sensorless differential pressure control with dynamic pressure compensation does

not work if the Dynamic Pressure Compensation Method (3-9-3-1) parameter has

been set to Speed.

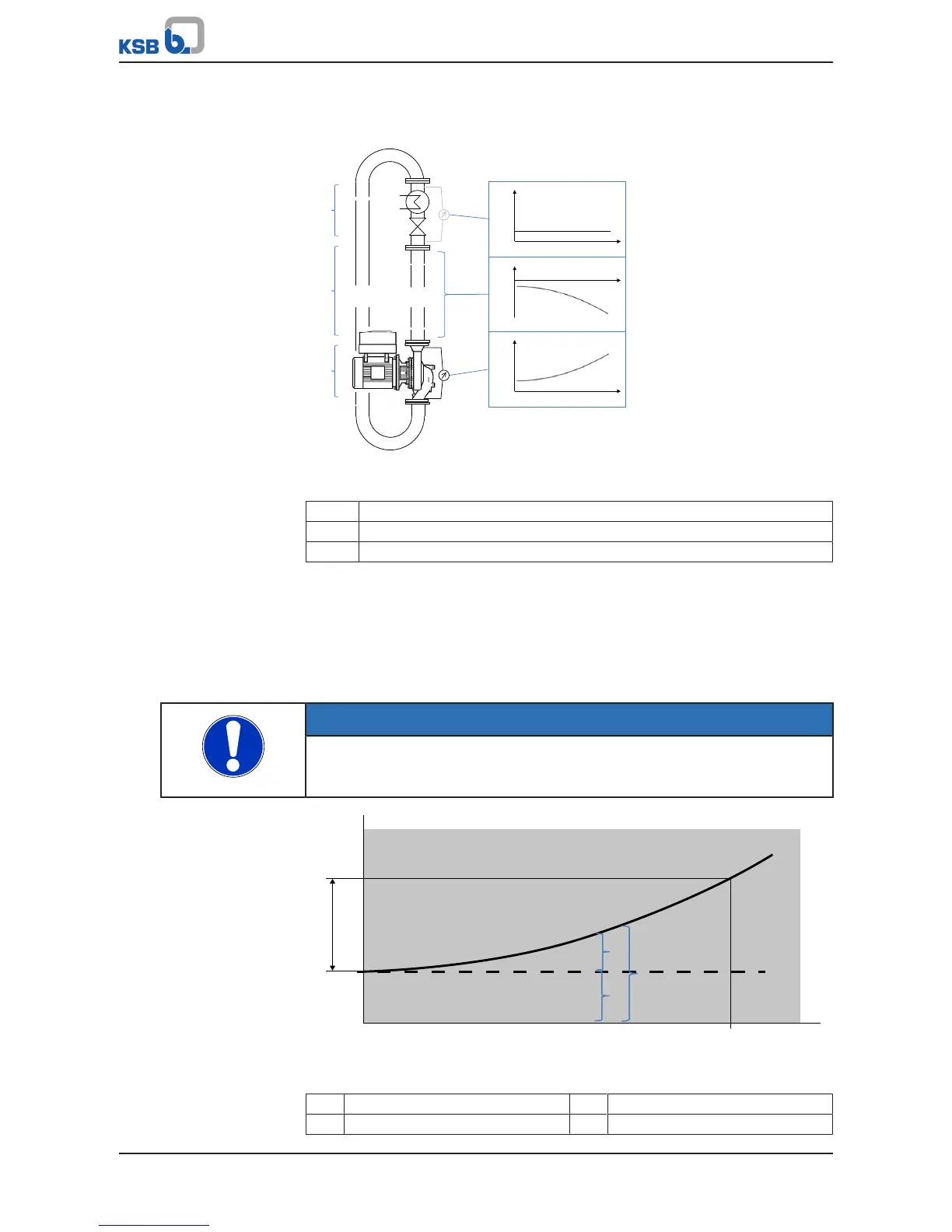

Fig.73: Setpoint compensation curve for dynamic pressure compensation based on

flow rate

1 Flow rate independent setpoint 2 Setpoint Compensation

3 Compensated setpoint

Loading...

Loading...