8 Commissioning/Shutdown

79 of 212

PumpDrive 2

Parameter Description Possible settings Factory setting

3-8-2-2 Analog Input 2 Function

Function of analog input2. Internal

operating values cannot be used as an

actual value source.

Differential Pressure OFF

3-8-2-3 Analog Input 2 Lower Limit 0,00 0,00

3-8-2-4 Analog Input 2 Upper Limit 10,00 100,00

1-3-1 System Start / Stop

This function is used to start the system.

Start Stop

NOTE

The System Start/ Stop parameter (1-3-1) must be set to Stop if the system start

takes place via the digital input.

8.7.1.2.2 Closed-loop control mode with external setpoint signal

The setpoint can be specified via an external setpoint signal. If a setpoint is

simultaneously specified via the control panel, the setpoint via the analog input has a

higher priority (ðSection8.2,Page65) .

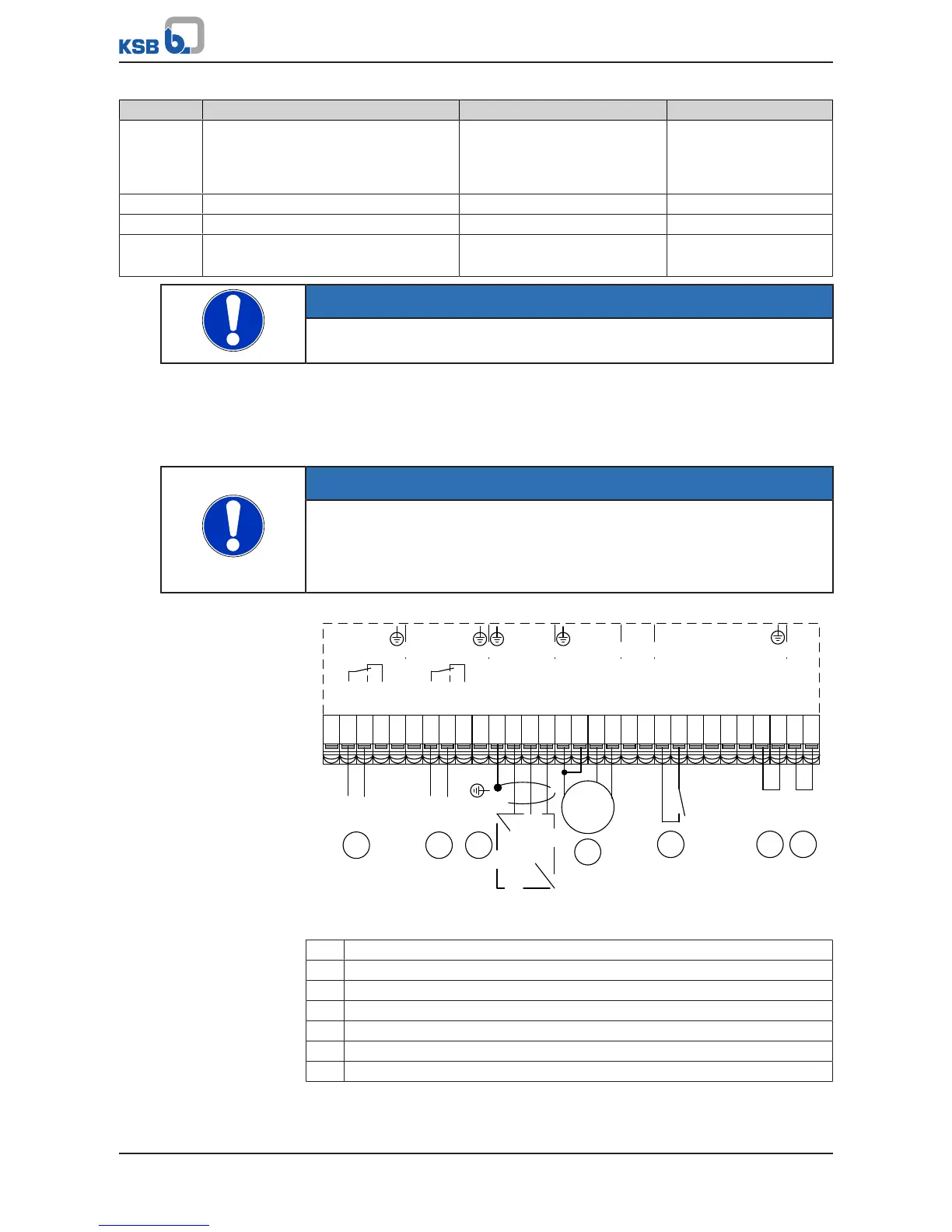

NOTE

The parameter values and value ranges/units entered are mutually dependent. This

is why the first step in parameterising the frequency inverter is always to specify the

applicable value range and units (refer to parameter 3-11). If the value range or

unit is subsequently changed, all dependent parameters must be checked for

correctness again.

Fig.60: Terminal wiring diagram, closed-loop control mode (dashed line = optional)

1 Start / Stop 2

2 Feedback value transmitter

3 Signal relay 1 (ðSection8.10.3,Page120)

4 Signal relay 2 (ðSection8.10.3,Page120)

5 Digital enable input

6 Ground for digital inputs

7 External setpoint signal

Example

The frequency inverter is to control the system to achieve a setpoint of 6.7bar in a

differential pressure control process. For this purpose, a differential pressure sensor

(4 - 20mA) with a measuring range of 0 to 10bar is connected to analog input 2 of

Loading...

Loading...