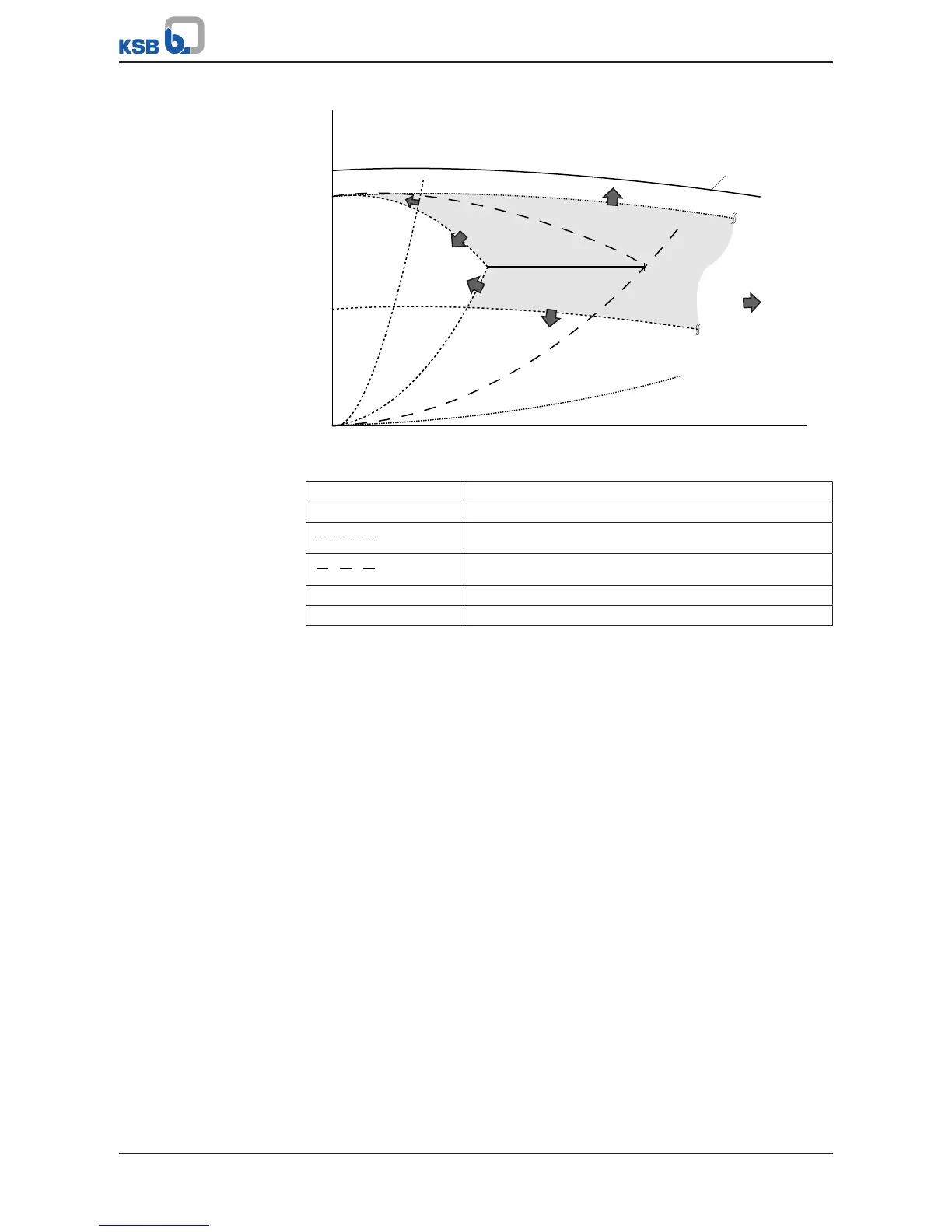

Fig.62: Switching limits of two running pumps in a multiple pump system

1 Characteristic head curve of a running pump

2 Characteristic head curve of two running pumps

Stop limits: Stopping the second pump

Start limits: Starting the third pump

Arrows Effective direction of the switching limits

Coloured area Operating range of two running pumps

KSB PumpDynamicControl (3-7-3-6):

This parameter determines the position of the stop limits relative to the start limits;

see "Switching limits of two running pumps in a multiple pump system" diagram and

greatly impacts the dynamic response and energy efficiency of the system. The

parameter can be defined anywhere from 0% for maximum energy efficiency to

100% for maximum dynamic response.

Low values mean that only the number of pumps required from a practical energy

perspective operate, or run. Fast, extensive changes in demand may possibly be

responded to with a delay as switching operations occur relatively frequently. Values

which are set too low, however, can lead to unstable starting and stopping cycles.

High values enable quick response to fast, extensive changes in demand as a

relatively large number of pumps run and switching operations do not occur as

frequently. High values can also lead to high energy consumption, however. The

following procedure is recommended for setting this parameter: Starting with a low

value (e.g. 10%), the parameter is gradually increased until the response time of the

multiple pump system suits the application. If this is already the case with the initial

value set, decreasing the value may prove even more beneficial.

Minimum Time Between Starts (3-7-3-1):

This parameter defines the minimum period of time that must lapse before a

subsequent start is carried out. Setting this parameter can prevent a second pump

from being started while a pump that was started just before is still running up to its

target speed along the start ramp. The minimum period of time between two starts

(3-7-3-1) should therefore be coordinated with the start ramp time (3-3-5-1). An

appropriate setting is achieved by selecting roughly the same times.

Minimum Time Between Stops (3-7-3-2):

This parameter defines the minimum period of time that must lapse before a

subsequent stop is carried out. Setting this parameter can prevent a second pump

from being stopped while a pump that was stopped just before is still running down

Loading...

Loading...