8 Commissioning/Shutdown

76 of 212

PumpDrive 2

The PID process controller is set using the following parameters:

Parameter (3-6-4-2) defines the proportional constant of the controller. The control

deviation is transferred to the control value, amplified by the proportional gain.

To avoid a permanent control deviation, an integrating controller constant is

required for many hydraulic processes. For this purpose, parameter (3-6-4-3) is used

to define the integral time of the integral constant. The control deviation is

integrated over time, weighted in relation to the integral time selected and added to

the control value. Reducing the integral time leads to faster adjustment or

compensation for the control deviation. When an integral time of 0s is selected, the

integral constant is deactivated.

By leveraging the differential constant, the controller can respond to a quick change

in the control deviation. Whether a differential constant is necessary is a function of

the dynamics of the hydraulic process; for typical centrifugal pump applications, it is

not required. When a rate time of 0s is selected, the differential constant of the

process controller is deactivated. The rate time of the differential constant is defined

using parameter (3-6-4-4). By increasing the rate time, the response to quick changes

in the control deviation is intensified. The Differential Constant Limitation parameter

(3-6-4-8) is used to define the maximum differential gain, which will help limit the

effect of measurement noise on the control value. Decreasing the limitation value

restricts the influence of the differential constant at high frequencies, and the

influence of measurement noise can be suppressed.

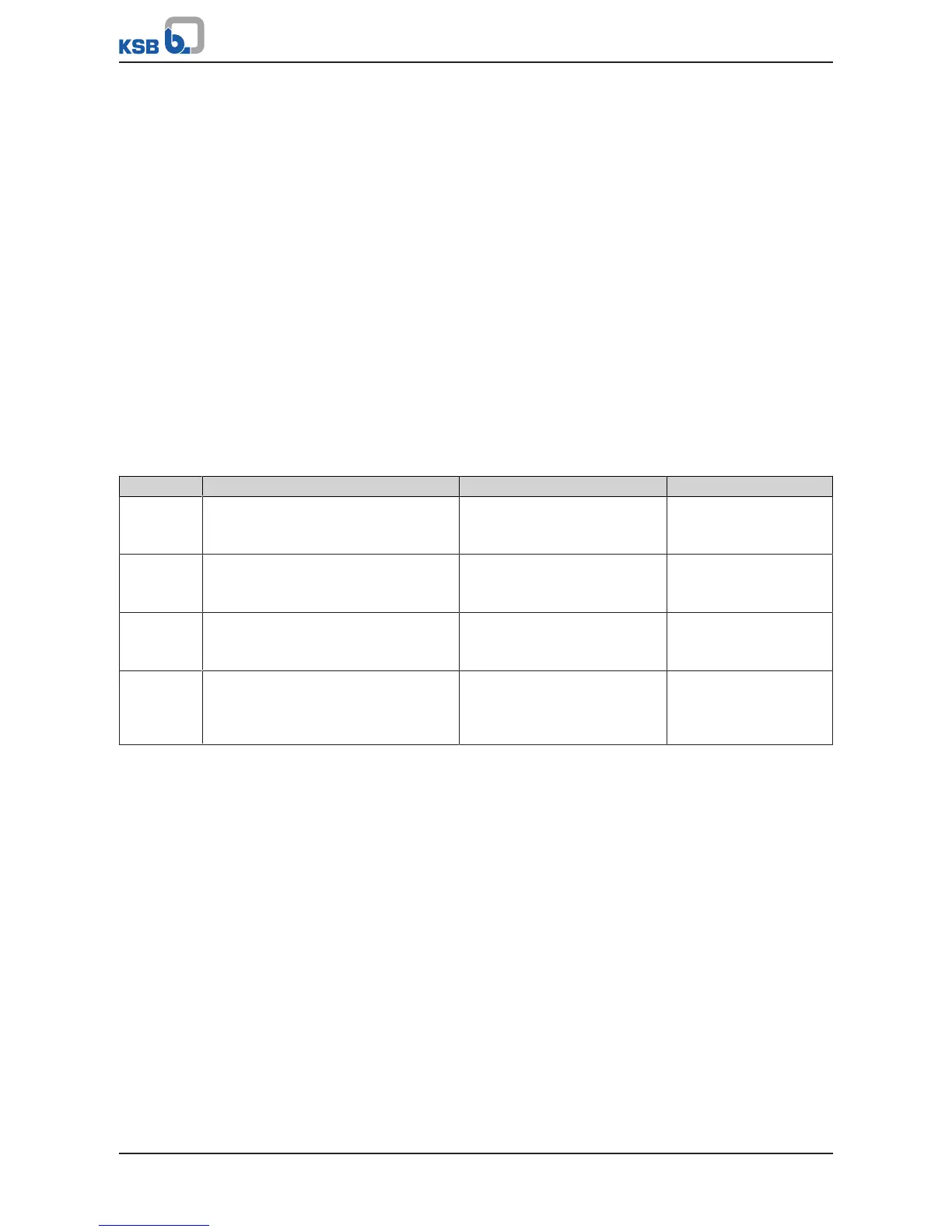

Table51: Parameters of the PID controller

Parameter Description Possible settings Factory setting

3-6-4-2 Proportional Constant

Setting the proportional constant of the

controller

0,01...100,00 1,00

3-6-4-3 Integral Time (Integral Constant)

Setting the integral constant of the

controller

0,0 to 9999,9 s 0,2 s

3-6-4-4 Rate Time (Differential Constant)

Setting the differential constant of the

controller

0,00... 100,00s 0,00s

3-6-4-8 Differential Constant Limitation

The maximum differential gain is limited in

order to suppress measurement noise, for

example.

1,00...20,00 3,00

Automatic determination of controller parameters

The parameters of the process controller can be determined automatically while the

hydraulic process is underway. To this end, a test sequence involving speed changes is

carried out and evaluated automatically. The test sequence is started as follows:

1. Operate the single-pump system or multiple pump system with the type of

control required using a PI controller and the relevant setpoint.

2. Run up the hydraulic system to reach the typical operating conditions in terms

of pressure and flow rate.

3. Once an adjusted and largely stable operating point is reached, start the test

sequence for automatically determining the controller parameters via

parameter 3-6-4-1-1.

ð The display now shows the Automatic Determination of Controller

Parameters Active message.

After the test sequence has been completed, the values determined for the

proportional constant, integral time and, if required, the rate time of the controller

are written to the respective parameters. In addition, the Operating Point parameter

(3-6-4-5) is als set to the current speed. The display now shows the Automatic

Determination of Controller Parameters Finished message.

The single-pump system or multiple pump system continues to operate uninterrupted

with the new controller parameters. If the process of determining the controller

parameters could not be completed correctly, the display shows the Automatic

Loading...

Loading...