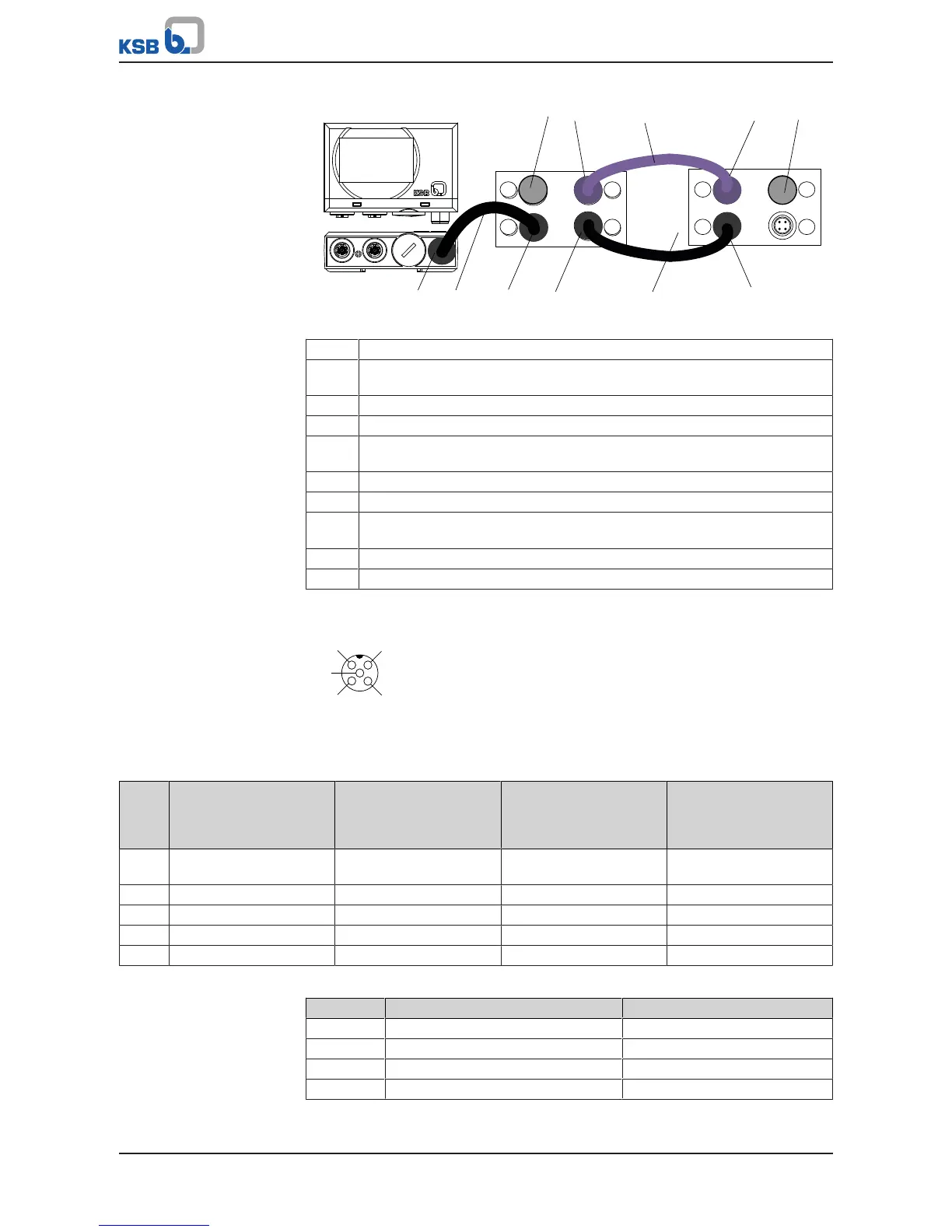

Fig.44: Connecting PumpMeter in dual and multiple pump configurations

1 PumpMeter: Modbus connection

2 Pre-configured bus cable for connecting PumpMeter to M12 module

(colour: black, socket: straight, connector: angled)

3 M12 module, socket A: Connection for PumpMeter (Modbus)

4 M12 module, socket B: Connection for bus cable crosslink (Modbus)

5 Pre-configured bus cable crosslink for redundant connection of PumpMeter

(colour: black, connector: angled; connector: angled)

6 M12 module, socket A: Connection for bus cable crosslink (Modbus)

7 Connection for dual/multiple pump configuration, PumpDrive No.1

8 Pre-configured bus cable for dual and multiple pump configuration

(colour: light purple, connector: angled, connector: angled)

9 Connection for dual/multiple pump configuration, PumpDrive No.2

10 Terminating resistor

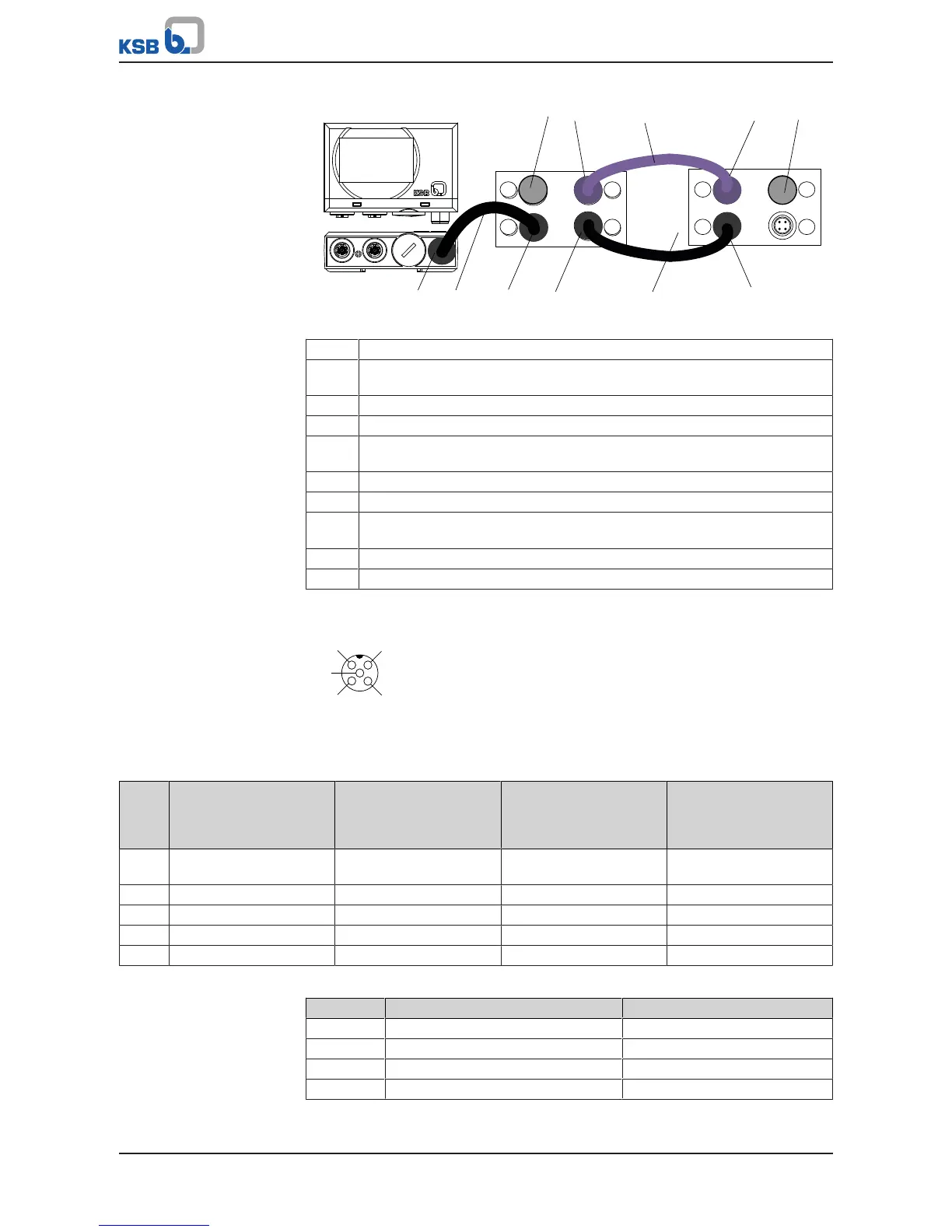

Pin assignment

Fig.45: M12 module standard assignment for M12 socket as viewed looking at the

mating face

Table31: Pin assignment, M12 module, input A/B

Pin Conductor colour coding M12 socket A assignment

parameterised for

PumpMeter Modbus

M12 socket B assignment

parameterised for

PumpMeter Modbus

M12 socket A and B

assignment

parameterised as analog

input

1 Brown 24 V output (supply to

PumpMeter)

24 V output (supply to

PumpMeter)

24 V output (supply to

PumpMeter)

2 Blue 0V 0 V 0 V

3 White D- D+ Input (4 - 20 mA)

4 Grey D+ D- -

5 - - - Vent opening

Table32: Pin assignment, M12 module, input C/D

Pin Conductor colour coding M12 socket C and D assignment

1 - Shielding

2 Red -

3 Black CAN GND

4 White CAN H

Loading...

Loading...