8 Commissioning/Shutdown

122 of 212

PumpDrive 2

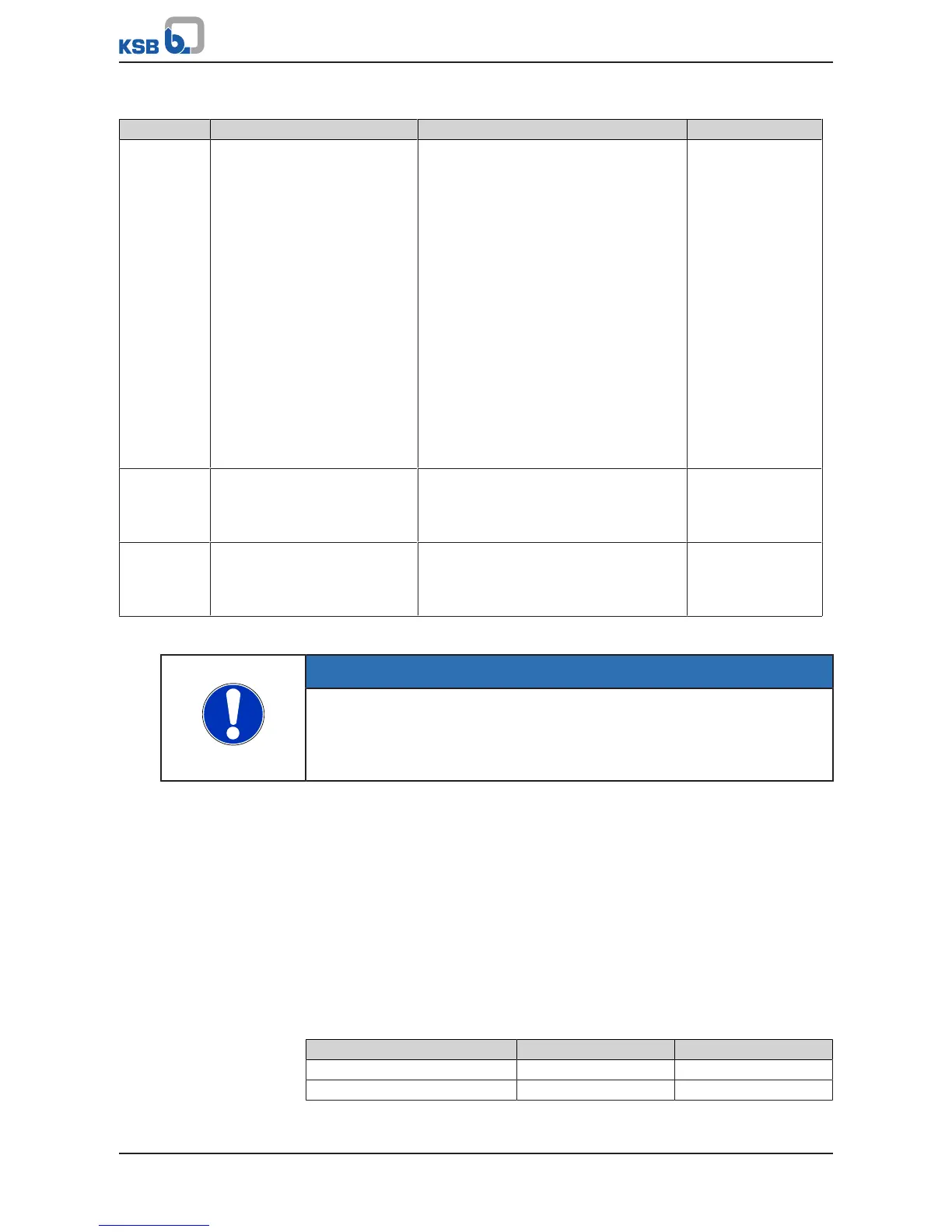

Table94: Parameters for relay2

Parameter Description Possible settings Factory setting

3-8-10-1 Relay 2 Function

Selectable messages via relay 2

▪ None

▪ AUTO operating mode

▪ RUN operating status

▪ AUTO/SLEEP operating status

▪ Warning

▪ Alert

▪ Alarm or warning

▪ Dynamic overload protection

▪ Current too high

▪ Current too low

▪ Frequency too high

▪ Frequency too low

▪ Power too high

Power too low

▪ Actual value = setpoint

RUN operating

status

3-8-10-2 Time Delay ON

Period of time during which the

event selected must be continually

available until the relay is set

0,0…10,0 s 0,5 s

3-8-10-3 Time Delay OFF

Period of time for which the event

selected must have gone before

the relay is reset

0,0 …10,0 s 0,5 s

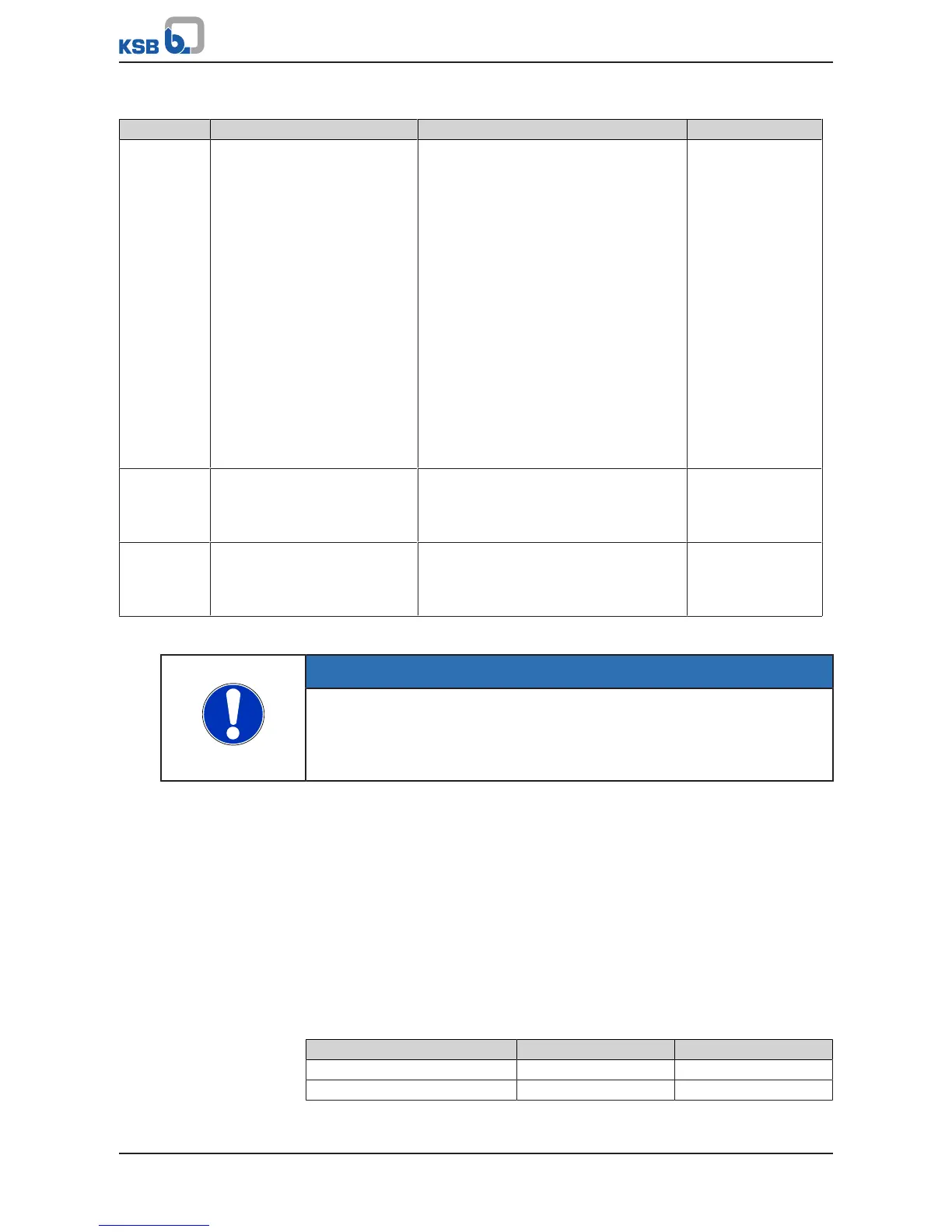

Actual Value = Setpoint function

NOTE

The parameter values and value ranges/units entered are mutually dependent. This

is why the first step in parameterising the frequency inverter is always to specify the

applicable value range and units (refer to parameter 3-11). If the value range or

unit is subsequently changed, all dependent parameters must be checked for

correctness again.

For the Actual Value = Setpoint function, after the value range and units are defined,

the bandwidth must be specified for comparing the actual value and setpoint data.

This is done via the Deviation Permitted when Actual Value = Setpoint (3-6-4-7)

parameter.

8.10.4 Analog outputs

By default, the value selected via parameter 3-8-7-1 (Assignment1, Analog Output1)

is output as a 4 - 20mA signal at the analog output. .

Four different process values can be assigned to the analog output.

The selection as to which value is output is made via two digital inputs (2 bits =

4options). For this purpose, parameterise the function of the digital inputs to

Control AOUT Bit 0 or Control AOUT Bit 1.

Table95: Controlling the output values

Assignment at analog output 1 Control AOUT Bit 1 Control AOUT Bit 0

1 0 0

2 0 1

Loading...

Loading...