8 Commissioning/Shutdown

127 of 212

PumpDrive 2

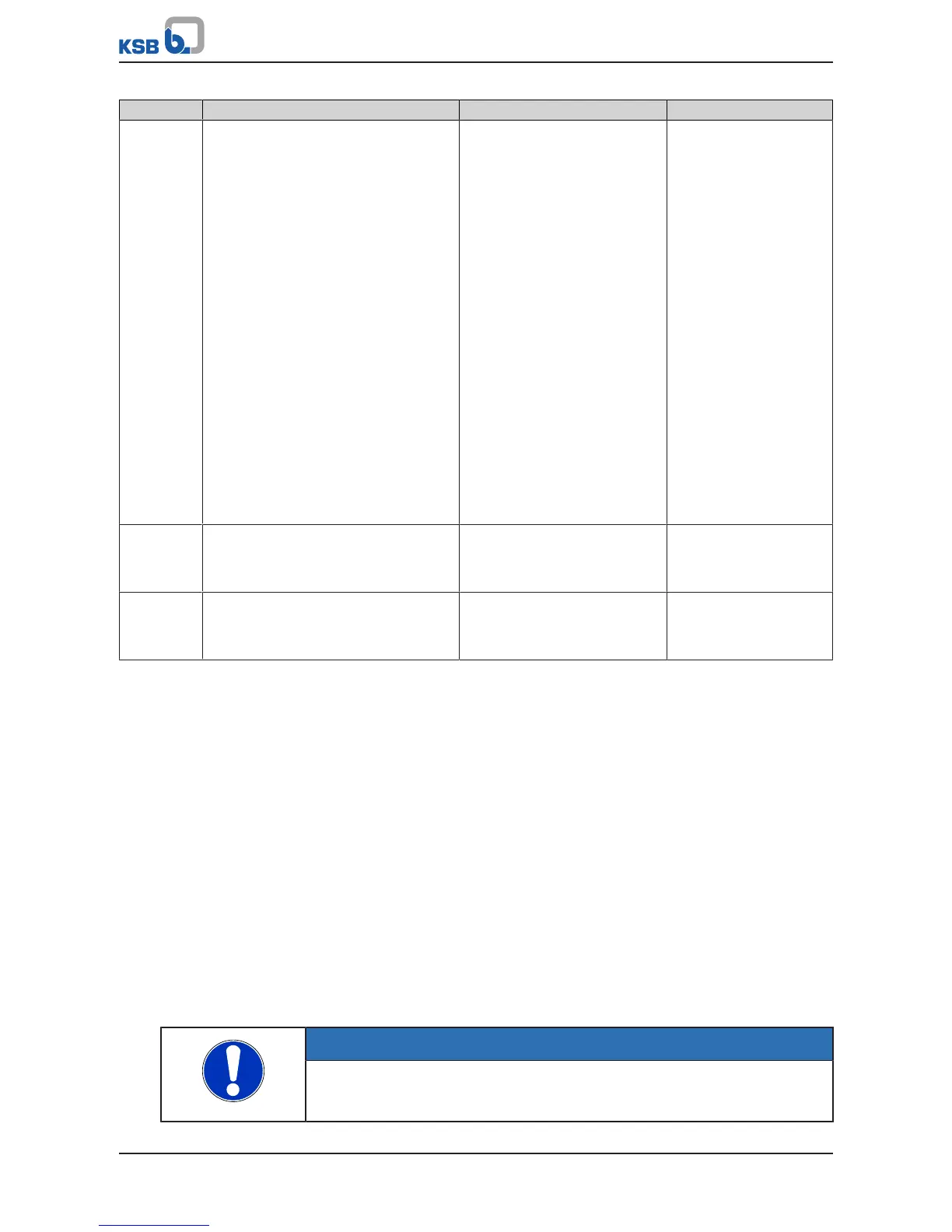

Parameter Description Possible settings Factory setting

3-8-18-1 Digital Output 2 Function

Selectable messages via digital output 1 of

the I/O extension board

▪ None

▪ AUTO operating mode

▪ RUN operating status

▪ AUTO/SLEEP operating

status

▪ Warning

▪ Alert

▪ Alert or Warning

▪ No alert

▪ Dynamic overload

protection

▪ Current too high

▪ Current too low

▪ Frequency too high

▪ Frequency too low

▪ Power too high

▪ Power too low

▪ Actual value = setpoint

▪ Motor Running

OFF

3-8-18-2 Time Delay ON

Period of time during which the event

selected must be continually available until

the digital output is set

0,0…600,0 s 0,5 s

3-8-18-3 Time Delay OFF

Period of time for which the event selected

must have gone before the digital output is

reset

0,0…600,0 s 0,5 s

8.11 Parameterising the M12 module

Installing an M12 module

(ðSection7.4.3.5,Page49)

If a function is parameterised at an M12 module socket contact (A or B) without such

a signal present at the device, the frequency inverter reports one of the following

messages:

▪ Failure of Actual Value warning

▪ No Master Control alert

▪ Broken Wire warning

This depends on whether the signal is to be used as an actual value source.

(ðSection8.8.2.6,Page91) It is not possible for the same M12 module socket

contact to be parameterised differently for the individual frequency inverters used in

multiple pump configurations.

Parameterising the M12 module for PumpMeter as an actual value source (via

Modbus)

If PumpMeter is connected to inputA of the M12 module via Modbus and used as

actual value source for control, the Function M12 Module Input A parameter must be

set to PMtr Suction / Discharge Pressure (3-8-4-1).

NOTE

When changing parameter 3-8-4-1 to the above-mentioned value (in particular in

retrofit applications) a 24 V voltage reset is triggered, which is required for

initialisation of the bus connection to PumpMeter.

Loading...

Loading...