8 Commissioning/Shutdown

80 of 212

PumpDrive 2

the frequency inverter. The setpoint specification is made as an external setpoint

signal (4 - 20mA) via analog input1. For the desired setpoint of 6.7bar, 10.7mA

must be applied at analog input1. The system start is activated by the System Start /

Stop parameter (1-3-1). The frequency inverter starts as soon as it is set to automatic

or manual mode and the enable is given via DI-EN.

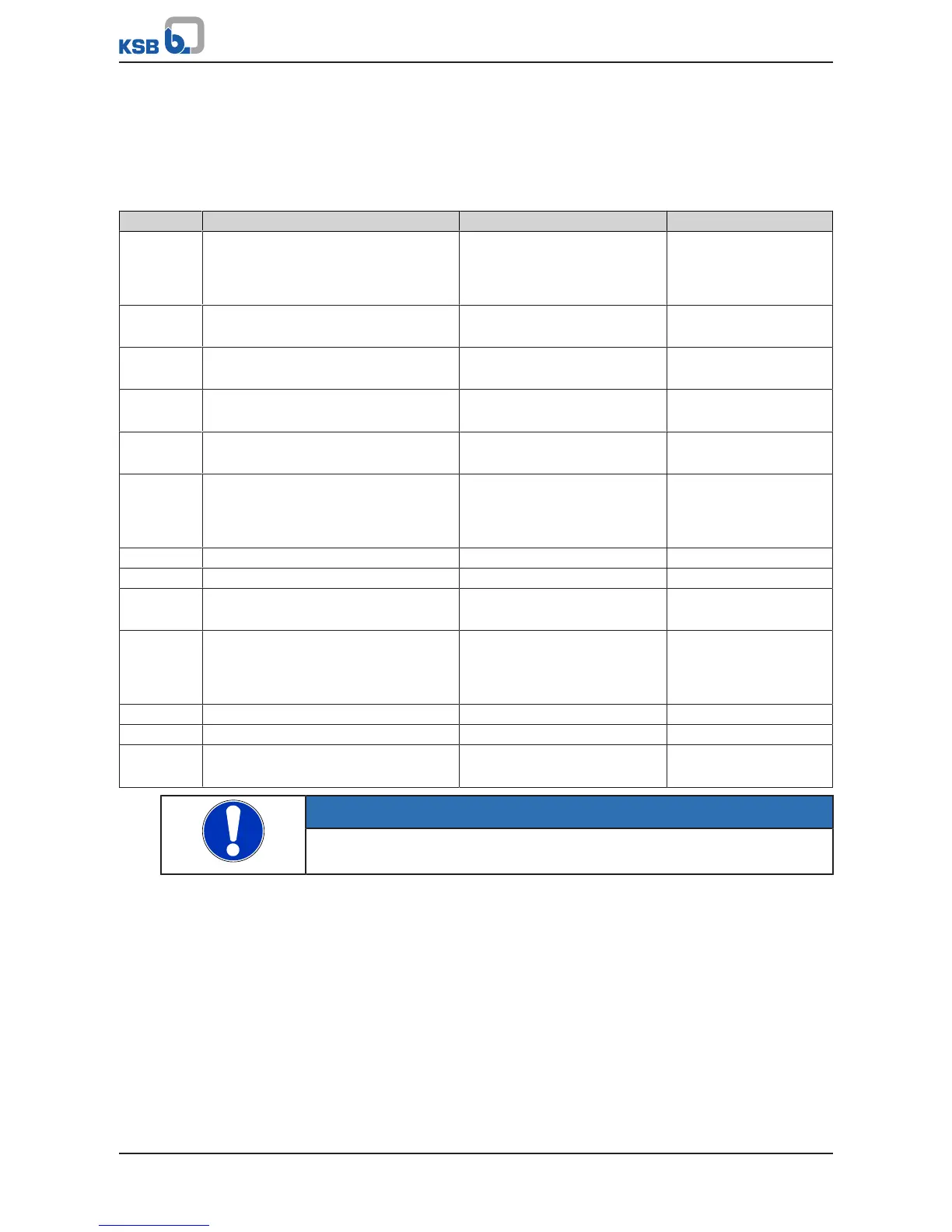

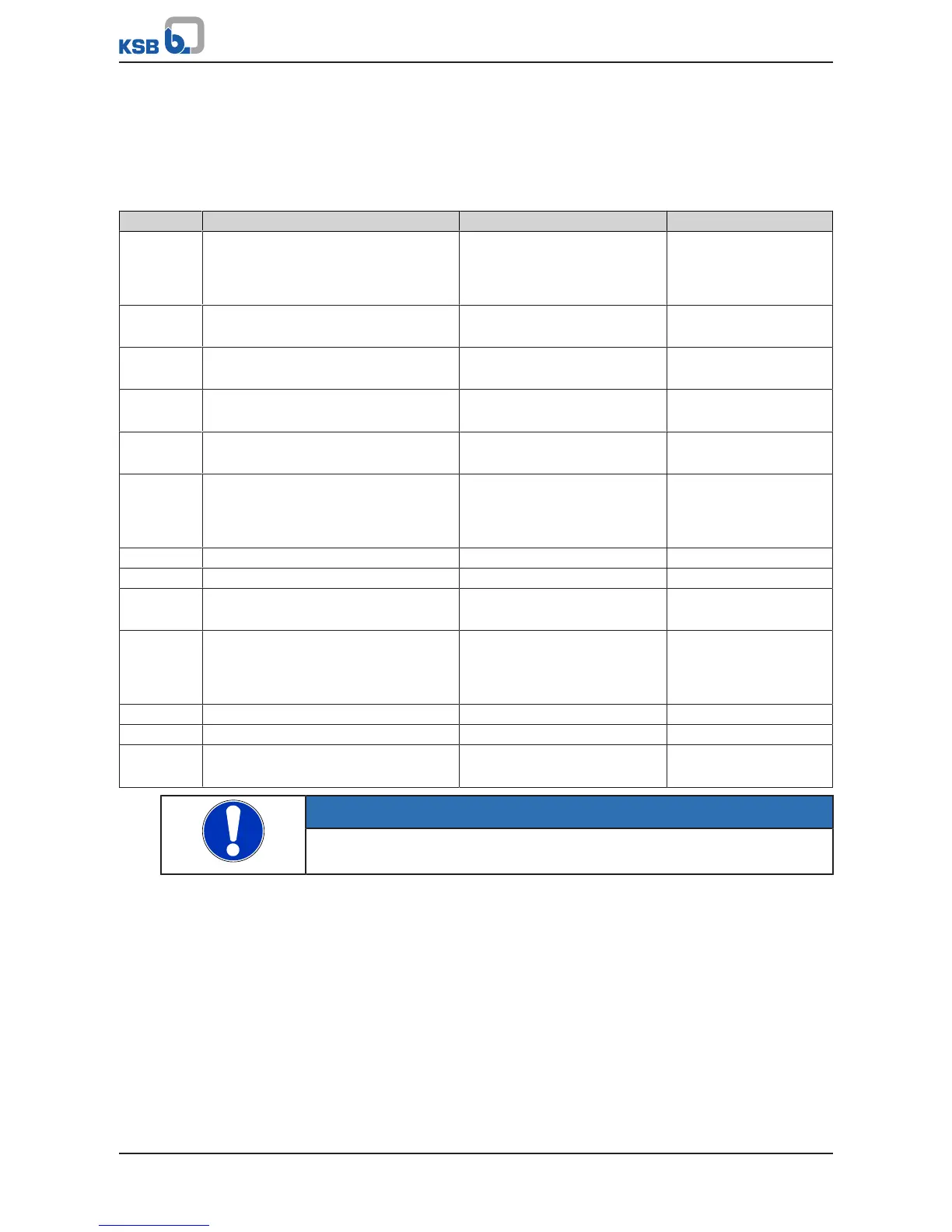

Table54: Example of closed-loop control mode with setpoint specification via external setpoint signal

Parameter Description Possible settings Factory setting

3-6-1 Type of Control

Selecting the control method. The

controller is deactivated when OFF (Open-

loop Control) is selected.

Differential Pressure Dependent on pump

3-11-2-1 Minimum Pressure

Minimum limit of measuring range

0,00 -1,00 bar

3-11-2-2 Maximum Pressure

Maximum limit of measuring range

10,0 1000,0 bar

3-11-2-3 Pressure Unit

Configurable unit for pressure 1

bar bar

3-8-1-1 Analog Input 1 Signal

Sensor signal at analog input 1

4…20mA OFF

3-8-1-2 Analog Input 1 Function

Function of analog input1. Internal

operating values cannot be used as an

actual value source.

Setpoint/Control Value (Auto) OFF

3-8-1-3 Analog Input 1 Lower Limit 0,00 0,00

3-8-1-4 Analog Input 1 Upper Limit 10,00 100,00

3-8-2-1 Analog Input 2 Signal

Sensor signal at analog input 2

4…20mA OFF

3-8-2-2 Analog Input 2 Function

Function of analog input2. Internal

operating values cannot be used as an

actual value source.

Differential Pressure OFF

3-8-2-3 Analog Input 2 Lower Limit 0,00 0,00

3-8-2-4 Analog Input 2 Upper Limit 10,00 100,00

1-3-1 System Start / Stop

This function is used to start the system.

Start Stop

NOTE

The System Start/ Stop parameter (1-3-1) must be set to Stop if the system start

takes place via the digital input.

8.7.1.2.3 Sensorless differential pressure control

Sensorless differential pressure control enables control to achieve a constant

differential pressure of the pump without the use of pressure sensors in a single-

pump configuration. The procedure is based on the characteristic curves of the pump.

Steep power curves are conducive to high process accuracy. The process is suitable to

a limited extent if sections of the power curve are constant over the flow rate or the

pump operates outside the permissible operating range. It is activated by setting the

Type of Control parameter (3-6-1) to Differential Pressure (Sensorless). Setting the

setpoint (ðSection8.6,Page70) .

Loading...

Loading...