7 Installation at Site

36 of 212

PumpDrive 2

Length of motor connection cable

If the frequency inverter is not mounted on the motor to be controlled, longer motor

connection cables may be required. The stray capacitance of the connection cables

may result in high-frequency discharge currents flowing to ground. The sum of the

discharge currents and motor current may exceed the output-side rated current of

the frequency inverter. This will activate the frequency inverter's protection

equipment and the motor will be stopped. The following motor connection cables

are recommended depending on the power range:

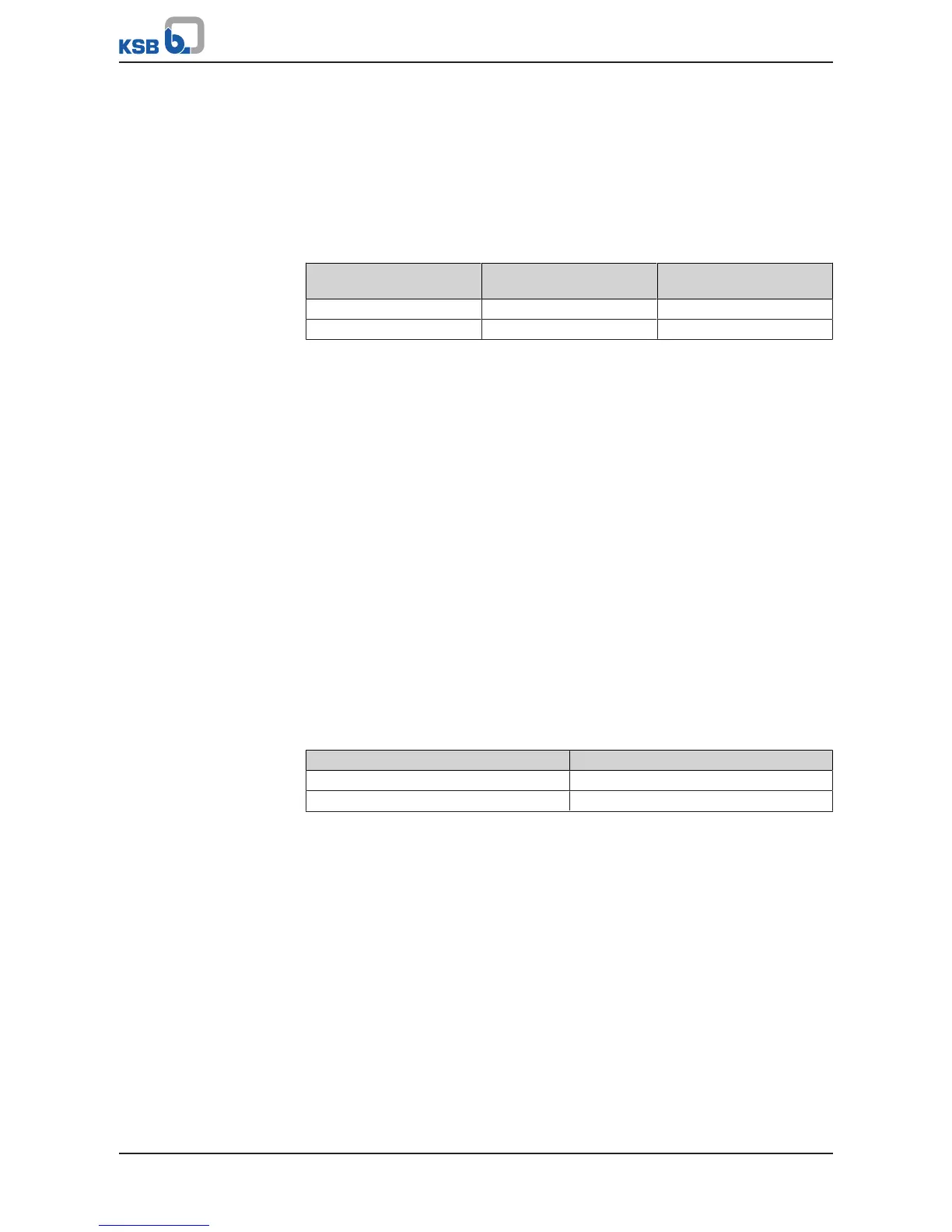

Table29: Length of motor connection cable

Power range

[kW]

Maximum cable length

[m]

Stray capacitance

[nF]

≤ 11 (Class B) 5 ≤ 5

≥ 15kW (class A, group 1) 50 ≤ 5

Output filter

Output filters can only be used in conjunction with an asynchronous motor.

If longer connection cables than those listed above are required or the connection

cable's stray capacitance value exceeds the above values, we recommend installing a

suitable output filter between the frequency inverter and the motor to be controlled.

These filters reduce the voltage ramp-up time of the frequency inverter output

voltages and limit their peaks.

7.4.2.2 Electrical protection device

Back-up fuses

Provide three fast-acting fuses in the mains power supply line to the frequency

inverter. The fuse size must be suitable for the nominal mains current supplied to the

frequency inverter.

Motor protection switch

Separate motor protection is not required because the frequency inverter has its own

safety devices (e.g. electronic overcurrent trip). Available motor protection switches

must be dimensioned in accordance with the nominal motor current.

Residual current device

If fixed connections and appropriate supplementary earthing are used (cf.

DINVDE0160), residual current devices (RCDs) are not mandatory for frequency

inverters.

If residual current devices are used, three-phase frequency inverters must in

accordance with DIN VDE 0160 be connected via universal AC/DC sensitive RCDs, as

potential direct-current components may cause standard AC sensitive RCDs to either

fail to respond or respond erroneously.

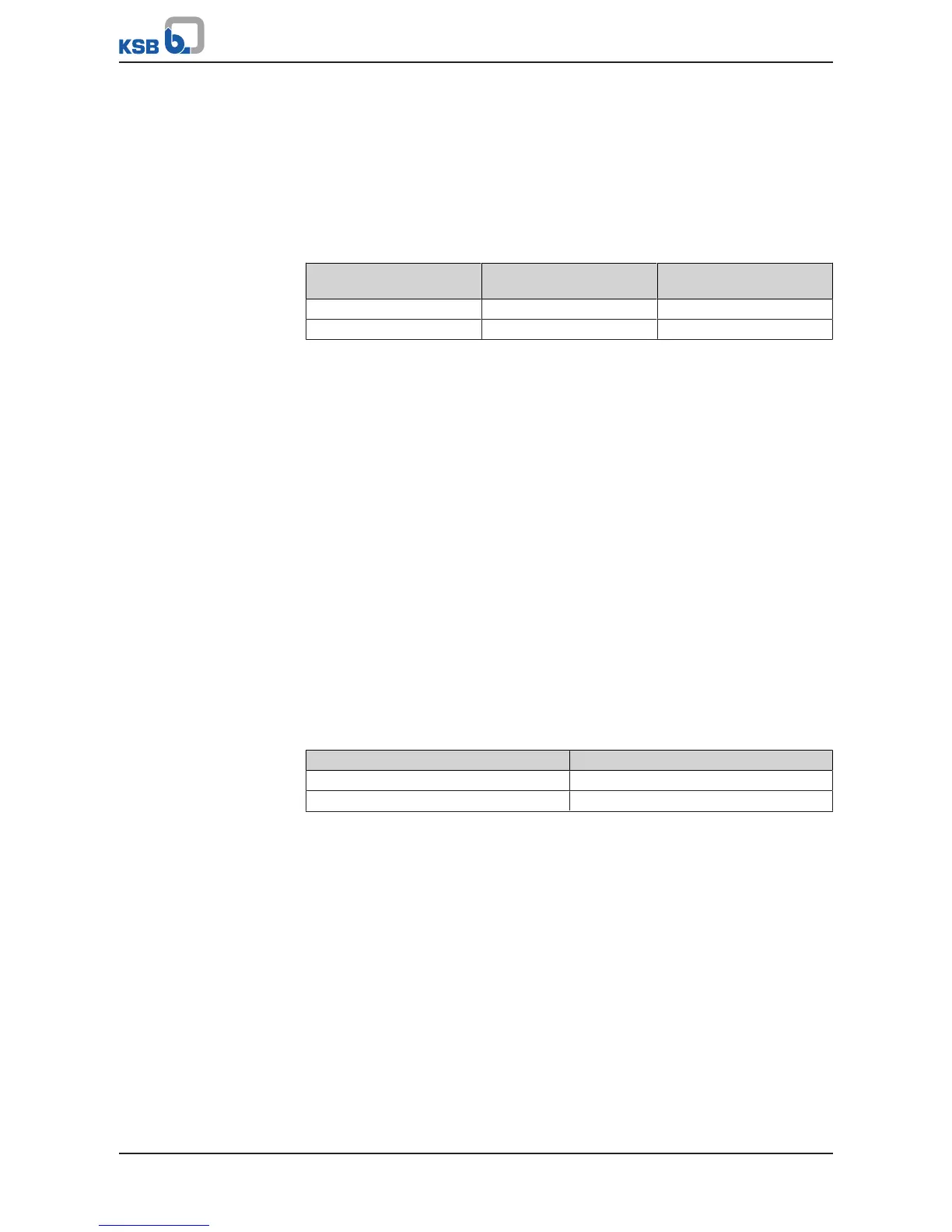

Table30: Residual current device to be selected

Size Rated current [mA]

A, B and C 150

D and E 300

If you use a long shielded cable for the mains/motor connection, the residual-current

monitoring device may be triggered by the discharge current that flows to earth

(triggered by the carrier frequency). Remedies: Replace the RCD (residual current

device) or lower the response limit.

7.4.2.3 Information on electromagnetic compatibility

Electromagnetic interference from other electrical devices can affect the frequency

inverter. Interference can also be emitted by the frequency inverter itself, however.

The interference emitted by the frequency inverter is generally conducted through

the motor connection cables. The following measures are proposed for RFI

suppression:

▪ Shielded motor connection cables for line lengths >70cm

(especially recommended for frequency inverters with low power ratings)

▪ Metal cable ducts made from a single piece with a minimum coverage of 80% (if

shielded connection cables cannot be used)

Installation at site/

environment

For more effective shielding, install the frequency inverter in a metal cabinet.

Loading...

Loading...