8 Commissioning/Shutdown

97 of 212

PumpDrive 2

Improving accuracy with pressure sensors installed close to the pump

Signals sent from pressure sensors installed close to the pump can be used to improve

the accuracy of flow rate and head estimations. They should only be used, however,

if the pressure loss between the pump nozzle and pressure measuring point is

negligible both on the suction and discharge side (< 1% of the sensor measuring

range). If this requirement is not met, the Pressure Measuring Point Positions

parameter (3-5-2-4) must be set to the Distant from Pump value to deactivate the

influence of the pressure signals on flow rate estimation. Otherwise, the Close to

Pump default setting with activated accuracy improvement function applies. The

pressure measuring points must be described by parameters (refer to table on flow

rate estimation parameters).

Pressures that are recorded via analog inputs with the Suction Pressure_Internal,

Discharge Pressure_Internal or Differential Pressure_Internal function are only used

to improve the accuracy of the flow rate and head estimation. They are always

regarded as "close to pump" sensors, regardless of the Pressure Measuring Point

Positions (3-5-2-4) parameter.

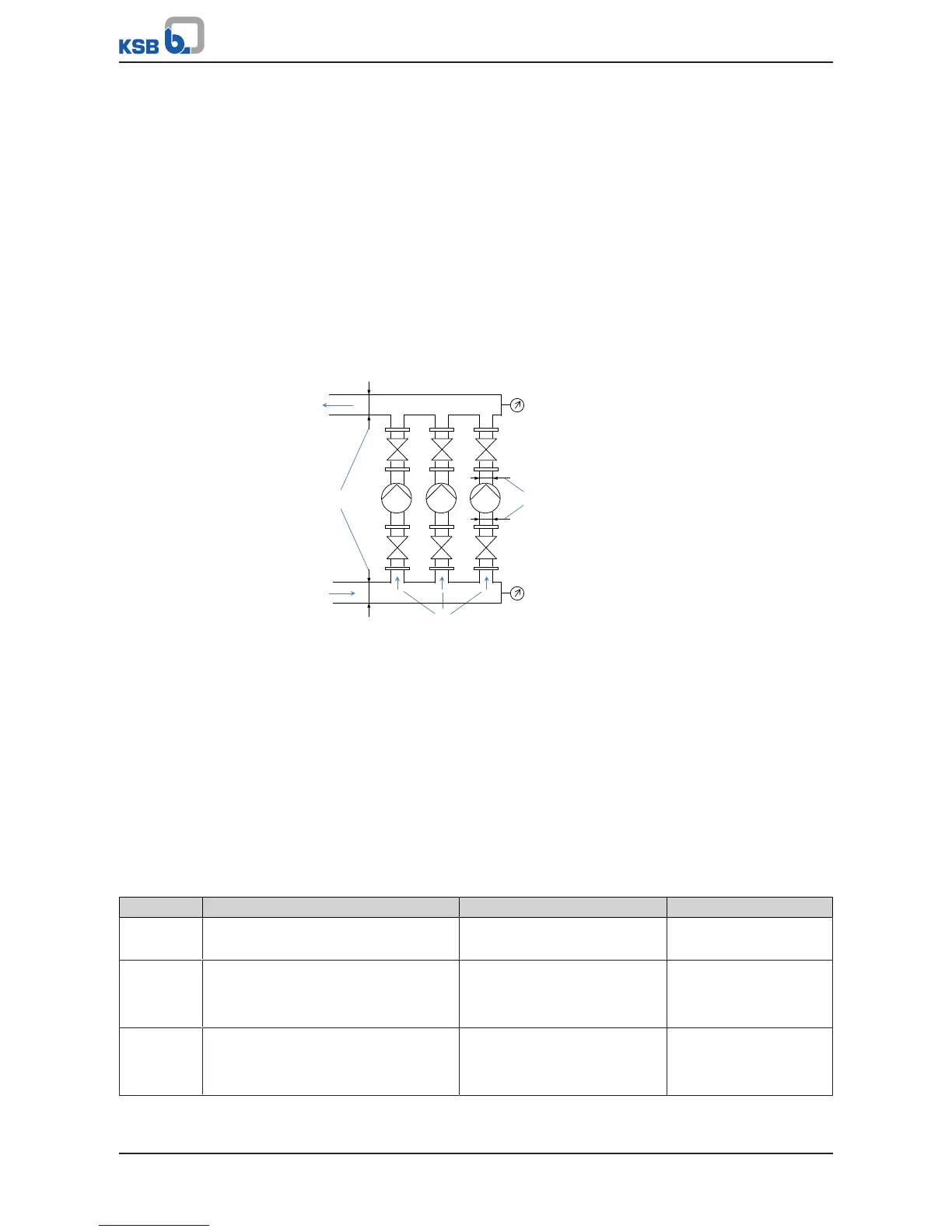

Multiple pump systems

Fig.66: Conditions for improving accuracy with pressure sensors installed close to the

pump in multiple pump systems

The following additional conditions must be fulfilled for multiple pump systems in

which pressure measurements are only taken in collecting lines (or headers/

manifolds):

▪ All of the pumps are identical in design.

▪ Suction and discharge nozzles of the pumps have the same diameter (in-line

pumps).

▪ Suction and discharge-side collecting lines have the same diameter.

▪ The total flow rate is largely distributed equally across the individual pumps.

If these requirements are not met, the pressure signals may not be used to improve

the accuracy of the flow rate and head calculation. The Pressure Measuring Point

Positions parameter (3-5-2-4) must be set to the Distant from Pump value.

Table71: Flow rate estimation parameters

Parameter Description Possible settings Factory setting

3-9-8-1 Flow Rate Estimation

Activation of flow rate estimation

▪ OFF

▪ ON

ON

3-5-2-1 Inside Pipe Diameter, Suction Pressure

Measuring Point

Inside pipe diameter at the suction

pressure measuring point

0...1000mm 0,0mm

3-5-2-2 Pipe Diameter, Discharge Pressure

Measuring Point

Inside pipe diameter at the discharge

pressure measuring point

0...1000mm 0,0mm

Loading...

Loading...