8 Commissioning/Shutdown

90 of 212

PumpDrive 2

8.8.2.2 Electrical motor protection by overvoltage/undervoltage monitoring

The frequency inverter monitors the mains voltage. If it falls below 380 V -10 % or

exceeds 480 V +10%, this results in tripping and an alert is output. The alert must be

acknowledged before the drive can be restarted.

8.8.2.3 Stop due to Overcurrent

NOTE

Should the Overcurrent and Short Circuit faults occur, the frequency inverter is

automatically reset (after 2s – 4s - 6s). If the fault still cannot be acknowledged,

the frequency inverter switches off for safety reasons, and fault messages A5 (Short

circuit)/A9 (Overcurrent) and A6 (Hardware fault) are output. The combination of

these faults indicates to the operator that all components of the system and their

electrical connections must be thoroughly checked. The frequency inverter can only

be restarted with a voltage reset after the fault present has been rectified.

If the Max. Motor Current in % of Nominal Motor Current (3-3-7-1) limit value is

exceeded by 5%, the partially self-acknowledging Overcurrent alert is output that

causes the motor to be stopped. The drive remains disabled as long as this event is

active. The Motor Disabled status is displayed on the control panel.

8.8.2.4 Dynamic Overload Protection by Speed Limitation

The frequency inverter is equipped with current sensors that record and limit the

motor current. When the defined overload limit is reached, the speed is lowered to

reduce the power (I²t control). The frequency inverter then no longer operates in

closed-loop control mode but maintains the operative function at a lower speed.

Based on the values set in the I²t Triggering Characteristic (3-3-7-5) and the Max.

Motor Current in % of Nominal Motor Current (3-3-7-1) parameters, a dynamic time

period is calculated during which the motor may be operated at a current higher

than the Nominal Motor Current (3-2-1-4) until I²t control takes over. The more the

motor exceeds its nominal current, the faster the I²t control mode is activated.

The first time dynamic overload protection (I²t counter=0) is activated and the

motor current is at 110% of the nominal motor current (3-2-1-4), it will take

60seconds (3-3-7-5) for I²t control to take over as defined in the default factory

settings. If the overload current is below the maximum motor current, the dynamic

time period calculated is extended by a corresponding amount. If the motor

continues to operate at its nominal current following operation in overload mode,

the I²t control mode remains active. If the current drops to a value below the nominal

current of the motor (3-2-1-4), the I²t counter is reset. This process can take up to

10minutes, depending on the current at which the motor is currently operating.

As soon as I²t control is activated, the Dynamic Overload Protection warning is

displayed. This warning is self-acknowledging and is reset when I²t control is

deactivated.

When the I²t stop speed (3-3-7-6) is undershot, the partially self-acknowledging

Dynamic Overload Protection alert is output and the motor is stopped. The motor is

disabled. After the I²t threshold value is undershot, the motor restarts after a

maximum disable time of 10seconds has lapsed, depending on the size of the motor.

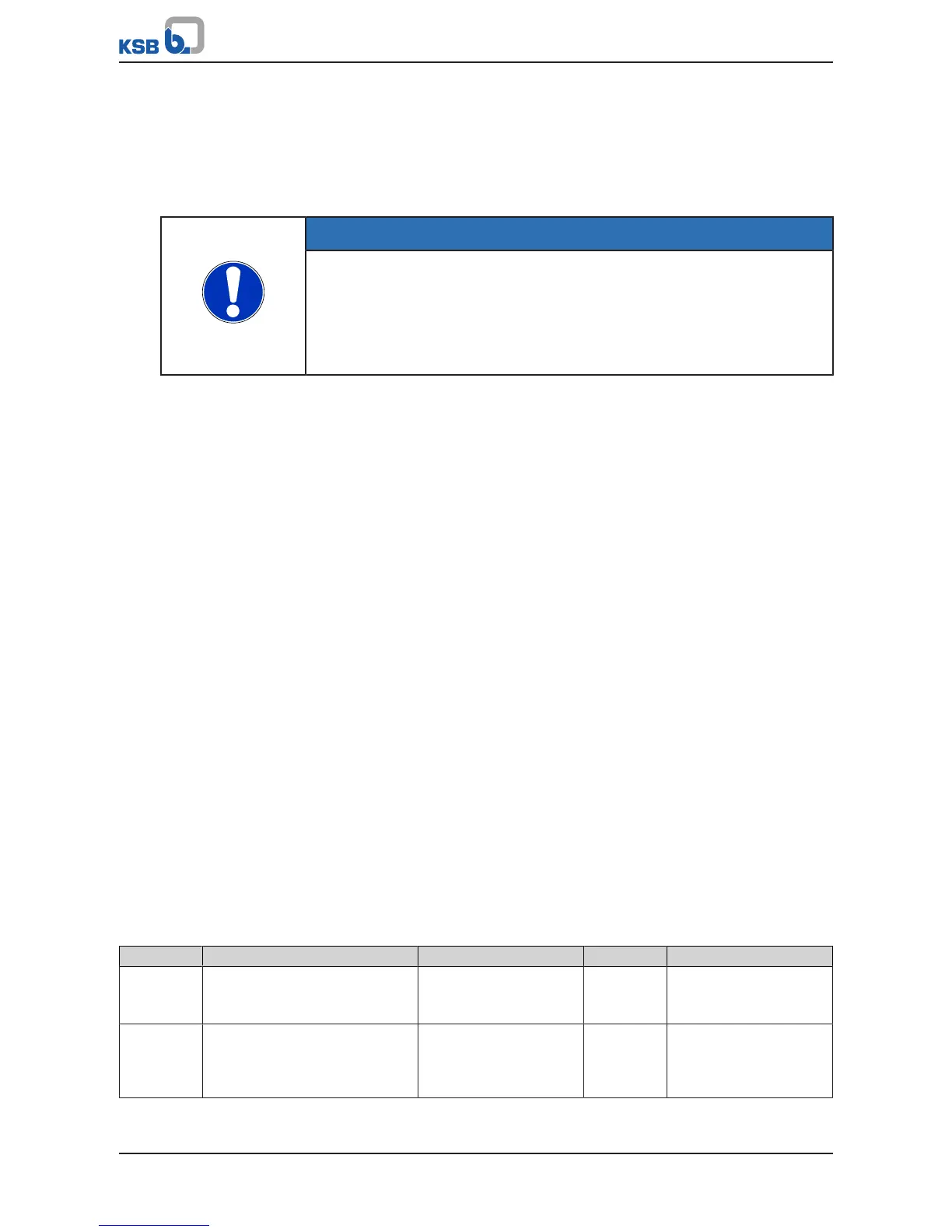

Table63: Parameters for dynamic overload protection by speed limitation

Parameter Description Possible settings Refers to Factory setting

3-2-1-4 Nominal Motor Current

Nominal current of motor as per

name plate

0.00 ... 150.00 A - Dependent on size

3-3-7-1 Max. Motor Current in % of

Nominal Motor Current

Setting the maximum motor current

permissible

0 ... 150 % 3-2-1-4 110 %

Loading...

Loading...