8 Commissioning/Shutdown

91 of 212

PumpDrive 2

Parameter Description Possible settings Refers to Factory setting

3-3-7-5 I²t Triggering Characteristic

Based on the I²t triggering

characteristic, a period of time is

calculated dynamically during which

the motor may be operated at a

higher current until I²t control is

activated.

1 .. 60 s - 60 s

3-3-7-6 I²t Stop Speed

This speed limit causes a Dynamic

Overload Protection alert to be

output, at which time the motor is

stopped.

Minimum to maximum

speed of motor

- 3-2-2-1

8.8.2.5 Tripping at phase failure and short circuit

Phase failure and short circuit result in direct tripping (without stop ramp). This

protective function does not need to be parameterised.

8.8.2.6 Broken wire detection (live zero)

The control system monitors all analog inputs at which a sensor has already been

detected or for which a sensor has been permanently set for broken wire (live zero).

A prerequisite are signals with 4 - 20 mA or 2 - 10 V. If the lower voltage or current

value is defined as 0 V or 0 mA, cable integrity monitoring is not carried out for the

corresponding analog input. If the value falls below 4 mA or 2 V, a parameterisable

response is initiated after a parameterisable time delay.

If the sensor relates to the actual value source and dedicated control is no longer

possible due to a lack of redundancy, the No Master Control alert is output (or

otherwise, the Failure of Actual Value warning).

A Broken Wire warning is output if no control function is active. The alerts and

warnings are self-acknowledging. In the event of an alert (control no longer

possible), a configurable response is implemented:

▪ Stop all pumps

▪ Maintain speed

▪ Configurable speed

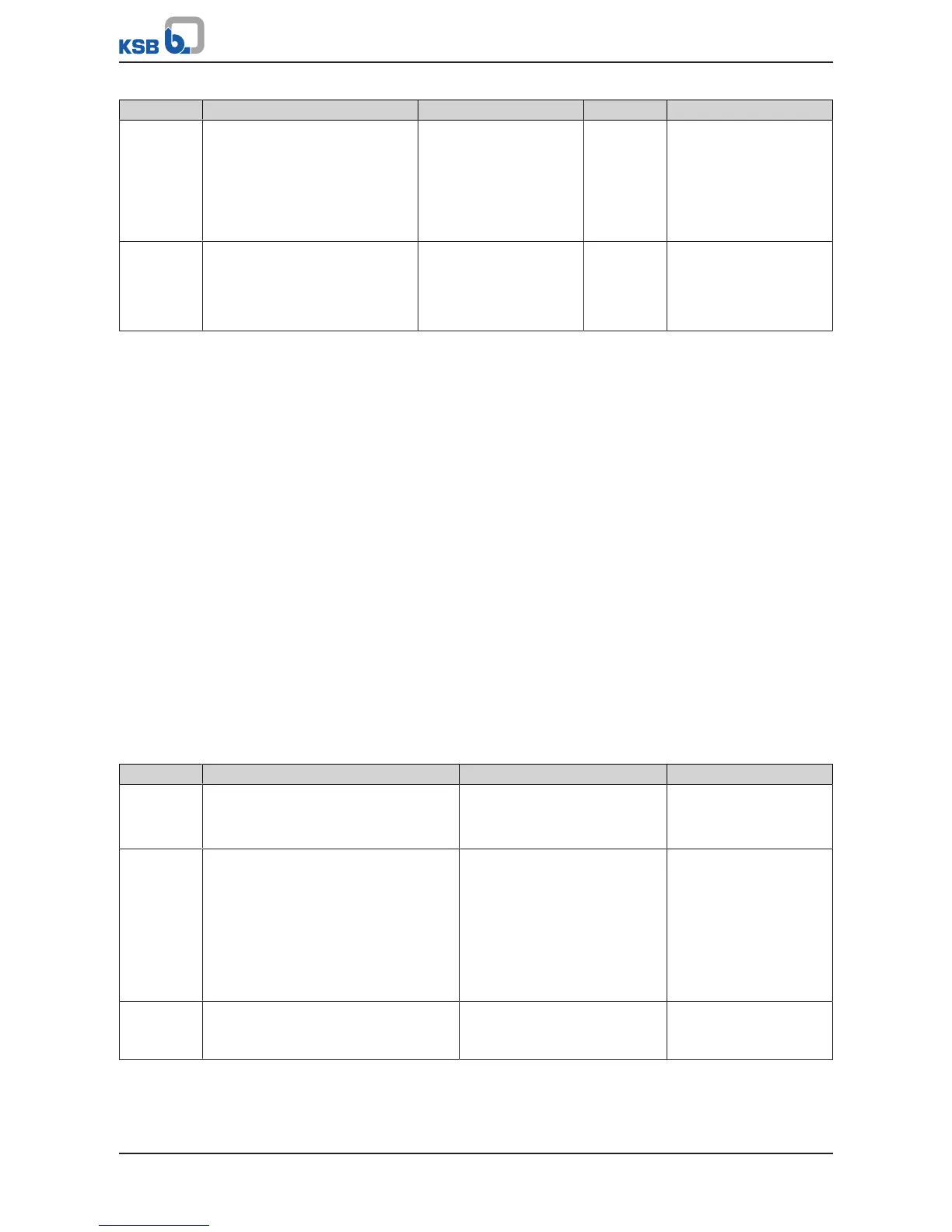

Table64: Broken wire detection parameter (live zero)

Parameter Description Possible settings Factory setting

3-9-1-1 Response to Failure

Operating behaviour of frequency inverter

upon Failure of Actual Value alert

▪ All Pumps OFF

▪ Maintain Speed

▪ Fixed Speed

Maintain Speed

3-9-1-2 Time Delay

Time delay before the message (warning

or alert) is triggered. In a redundant

system, only a warning is output as the

auxiliary master can assume the function.

Only if the actual value also fails at the

auxiliary master is an alert output, which

then triggers the specified response to

actual value failure (pump changeover).

0,0…10,0s 0,5s

3-9-1-3 Speed During Failure

Fixed speed that is activated when the

actual value fails.

Minimum to maximum speed of

motor

3-2-2-1

Loading...

Loading...