7 Installation at Site

56 of 212

PumpDrive 2

Connecting the field bus module

Observe the following when connecting the field bus module:

▪ Before the bus connection is established among the nodes, potential equalisation

must have been implemented and checked.

▪ To ensure high-frequency shielding, use suitable, shielded cables for the

respective field bus and install them in accordance with EMC requirements.

▪ A minimum distance of 0.3metres is recommended between such cables and

other electric conductors.

▪ Do not use the bus cable to make any further connections in addition to the field

bus module (for example, 230 V alert and 24 V start).

CAUTION

Incorrect installation

Damage to the field bus module!

▷ Never supply the field bus module with voltage using the M12 connector or the

M12 socket.

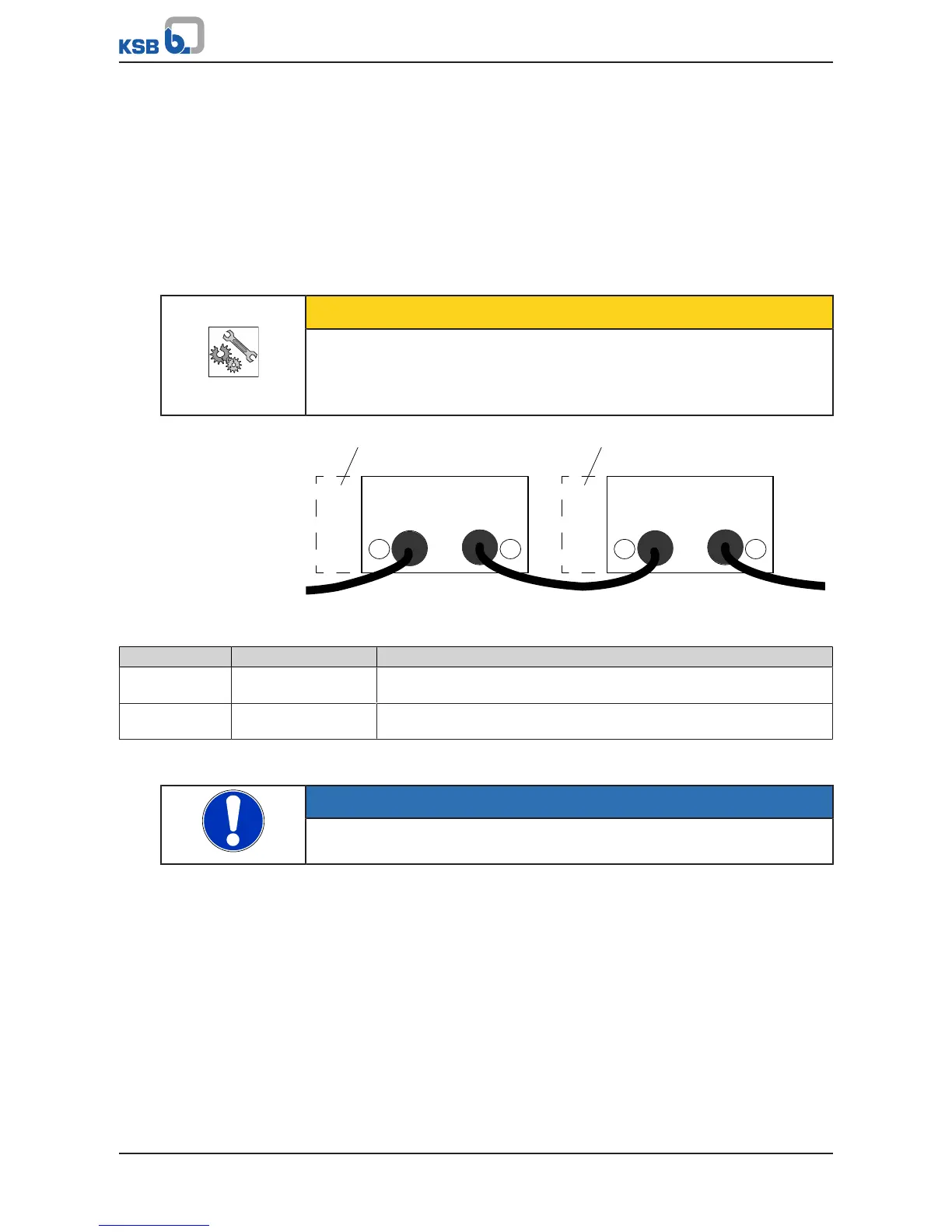

Fig.49: Connecting the field bus module

Table33: Connecting the field bus module

Item Design M12 connector

1 Frequency inverter 1 M12 connector A: Coming

M12 socket B: Going

2 Frequency inverter 2 M12 connector A: Coming

M12 socket B: Going

Field bus control must be activated in the frequency inverter when using the field bus

module (ðSection8.12,Page130) .

NOTE

The frequency inverter is reset when a field bus module is replaced or retrofitted.

Menu 3-12 for setting the parameters of the field bus module is then enabled.

7.4.3.7 Installing and connecting the I/O extension board

Additional inputs and outputs are made available by the I/O extension board:

▪ 1 analog input/PT1000

▪ 1 analog output

▪ 3 digital inputs

▪ 2 digital outputs

▪ 1 changeover contact relay

▪ 5 NO contact relays

The I/O extension board can be pre-installed at the factory or retrofitted as an

accessory.

Loading...

Loading...