8 Commissioning/Shutdown

131 of 212

PumpDrive 2

NOTE

If the field bus is only used for monitoring purposes, the Control Point parameter

3-6-2 is set to Local.

NOTE

The frequency inverter is reset when a field bus module is replaced or retrofitted.

Menu 3-12 for setting the parameters of the field bus module is then enabled.

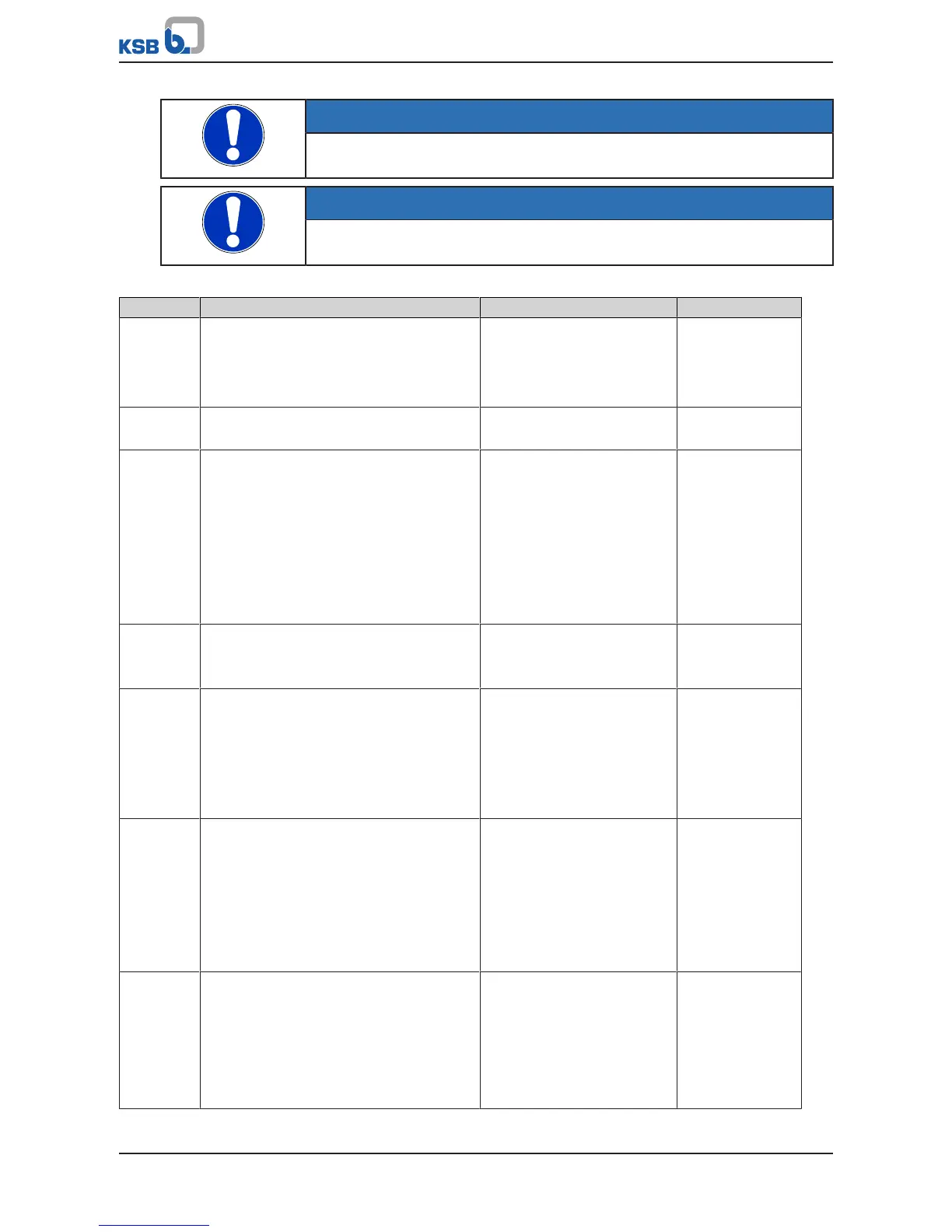

Table108: Modbus RTU Module parameters

Parameter Description Possible settings Factory setting

3-6-2 Control Point

Toggling the control point from Local to Field

Bus. DIGIN/ANIN have the highest priority. The

actual value source must be configured

separately.

▪ Local

▪ Field Bus

Local

3-12-2-1 Modbus Slave Address

Modbus slave address of the system

1 - 247 1

3-12-2-2 Baud Rate

Baud rate of the Modbus slave

▪ 1200

▪ 2400

▪ 4800

▪ 9600

▪ 19200

▪ 38400

▪ 56k

▪ 115k

19200

3-12-2-3 Parity

Parity of the Modbus slave

▪ Even

▪ Odd

▪ No parity

Even

3-12-2-4 Modbus Address Range of Pump

Configurable address range via which the local

parameters of the pump are addressed.

▪ 0x0100 - 0x1FF

▪ 0x0200 - 0x2FF

▪ 0x0300 - 0x3FF

▪ 0x0400 - 0x4FF

▪ 0x0500 - 0x5FF

▪ 0x0600 - 0x6FF

0x0100 - 0x01FF

3-12-2-5 Cycle Time, Setpoint/Control Value

Time delay before the message (warning or

alert) is triggered. In a redundant system, only

a warning is output as the auxiliary master can

assume the function. Only if the setpoint/

control value also fails at the auxiliary master is

the alert output, which then triggers the

specified response to setpoint/control value

failure.

0,0…10,0 s 5,0s

3-12-2-6 Cycle Time, Actual Value

Time delay before the message (warning or

alert) is triggered. In a redundant system, only

a warning is output as the auxiliary master can

assume the function. Only if the actual value

also fails at the auxiliary master is the alert

output, which then triggers the specified

response to actual value failure.

0,0…10,0 s 1,0s

Loading...

Loading...