11 Trouble-shooting

194 of 212

PumpDrive 2

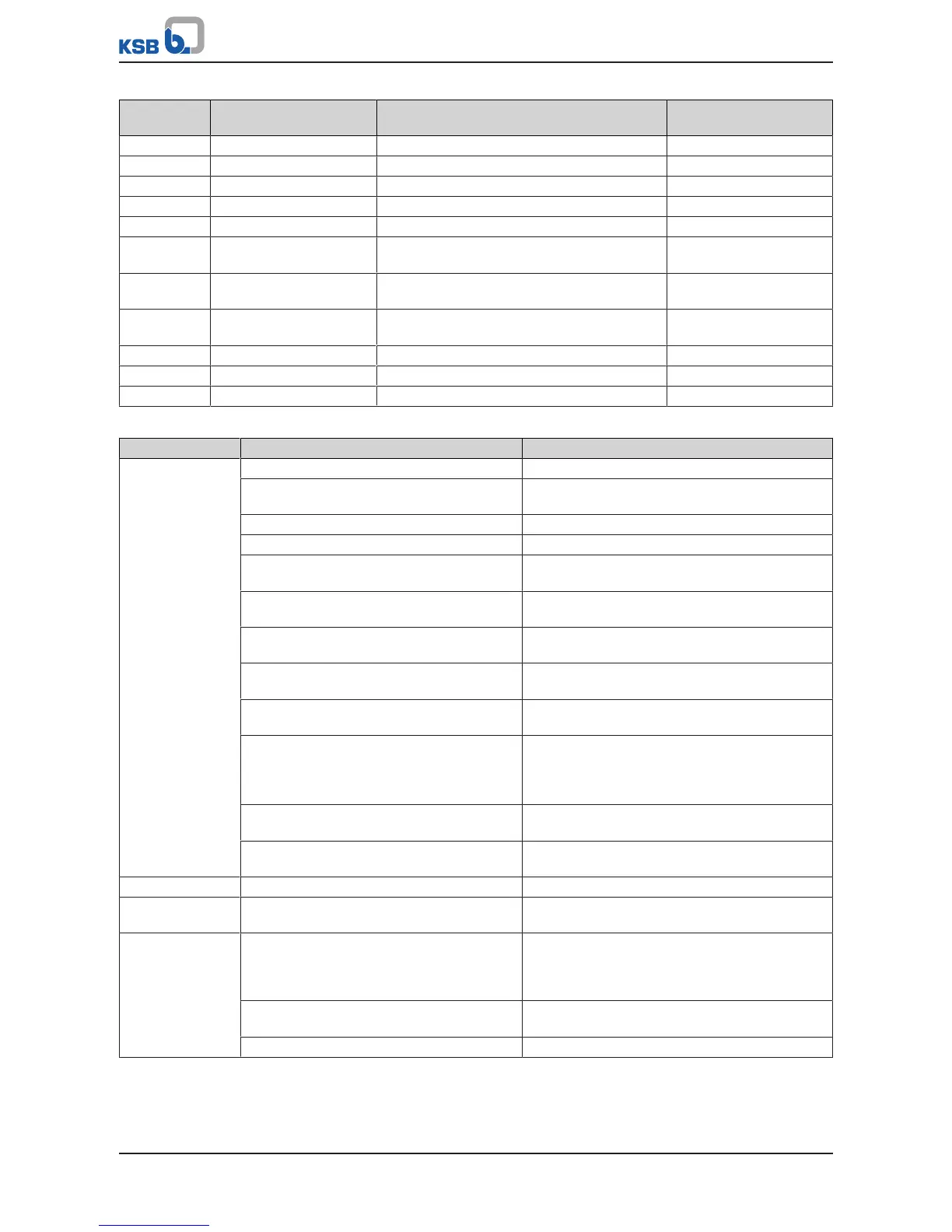

Message

number

Message Description Behaviour

W72 Frequency low Frequency low Self-acknowledging

W73 Power high Power high Self-acknowledging

W74 Power low Power low Self-acknowledging

W75 Limited stop ramp Set stop ramp time exceeded Self-acknowledging

W76 24V overload Internal 24V power supply unit overloaded Self-acknowledging

W77 PumpMeter

communication

Incorrect PumpMeter communication Self-acknowledging

W78 Firmware update for field

bus required

Module incompatible with main module Self-acknowledging

W79 Firmware update for HMI

required

Module incompatible with main module Self-acknowledging

W80 Low flow velocity Lower limit for flow velocity undershot Self-acknowledging

W81 Field bus communication Defective field bus module Self-acknowledging

W99 General settings loaded General settings loaded Self-acknowledging

Table118: Warnings

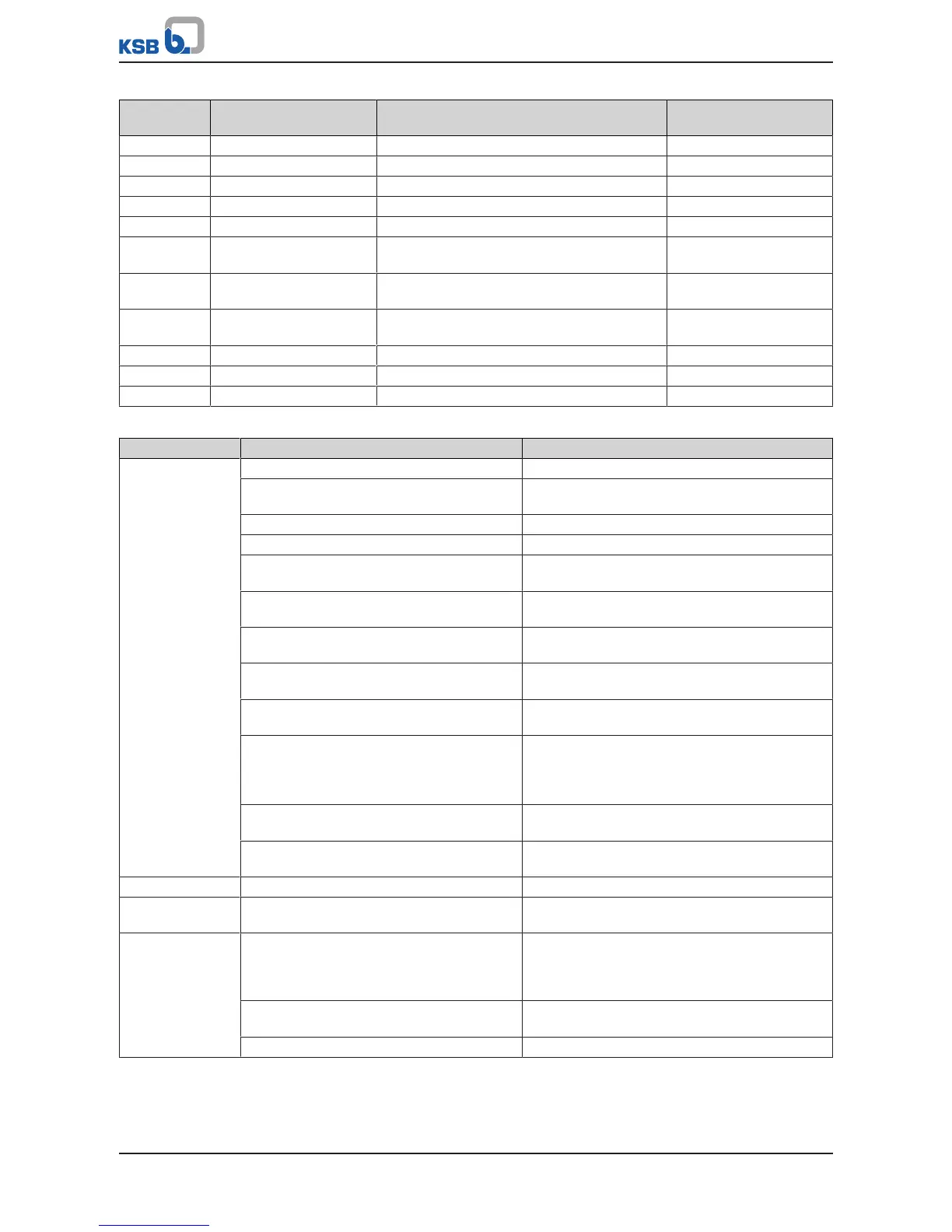

Warning Possible causes Remedy

Dynamic overload

protection

Incorrect motor data set Match motor data to motor used.

Wrong direction of rotation of the pump Change the direction of rotation of the motor via

the phase sequence.

Hydraulic overload Reduce the hydraulic load.

Pump blocked mechanically/runs sluggishly Check pump.

Motor terminal board wired incorrectly

(delta/star)

Wire motor terminal board correctly.

PumpDrive power < motor power or

Output current < motor current

Wrong device ordered; mount larger PumpDrive

model.

Frequency inverter carrier frequency set too

high

Set carrier frequency to permissible range.

Ambient temperature of PumpDrive > 50 °C Impermissible operating range; mind power

derating.

Fluctuating DC link voltage when pump is

not running

Check mains voltage quality.

Incorrect motor current measurement Measure current using suitable snap-on ammeter

and compare with the information displayed on

the control panel.

NOTE!Approx. 10% tolerance is permissible.

Pump runs in reverse when motor is not

supplied with current

Check swing check valve.

Motor voltage output is too low at nominal

load, < 380V at nominal load

Check line input voltage; enter motor current at

380V mains voltage; fit larger-sized motor.

Broken wire Cable integrity monitoring Replace defective sensor with new one.

Low flow/overload The driven pump is operated under low

flow/overload conditions

Impermissible operating range; operate the

pump within the permissible range.

24V overload 24 V DC voltage supply overload Reduce current input to 24 V DC, compare the

number of electrical connections with the

maximum permissible current load of the 24 V DC

supply .

Short circuit of consumers connected to

24VDC voltage supply

Disconnect defective 24VDC consumers.

Control terminal wiring errors (DigIn, AnIn) Re-wire properly.

Loading...

Loading...