12 Pellet Stirrer Plus

8.) Extension of the worm conveyor system

Different possibilities for extending the conveyor system are available

(MBDK0001 in section 17).

If an intermediate bearing is not required continue with step 9.

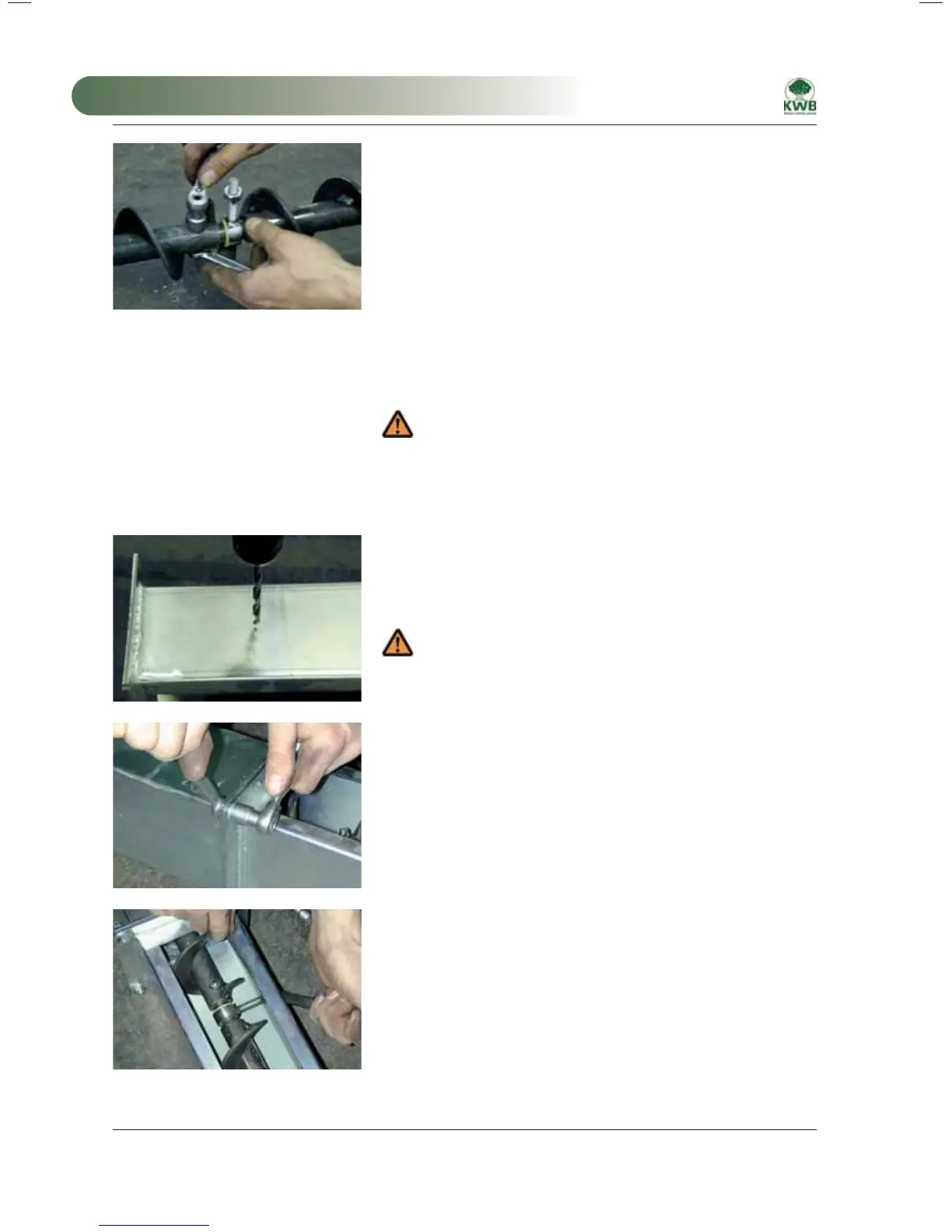

If an intermediate bearing is required for the extension, slide the

intermediate bearing onto the extension worm and guide the shaft end

through the hollow shaft as shown.

The two worm ends must be twisted in such a manner that they are

positioned approximately 180° relative to each other and the cross

hole is flush.

Fasten the connecting bolt.

The free shaft end must be supported at axis height until the

intermediate bearing is fastened in the trough.

Short extension worms do not need to be supported.

Extending the worm

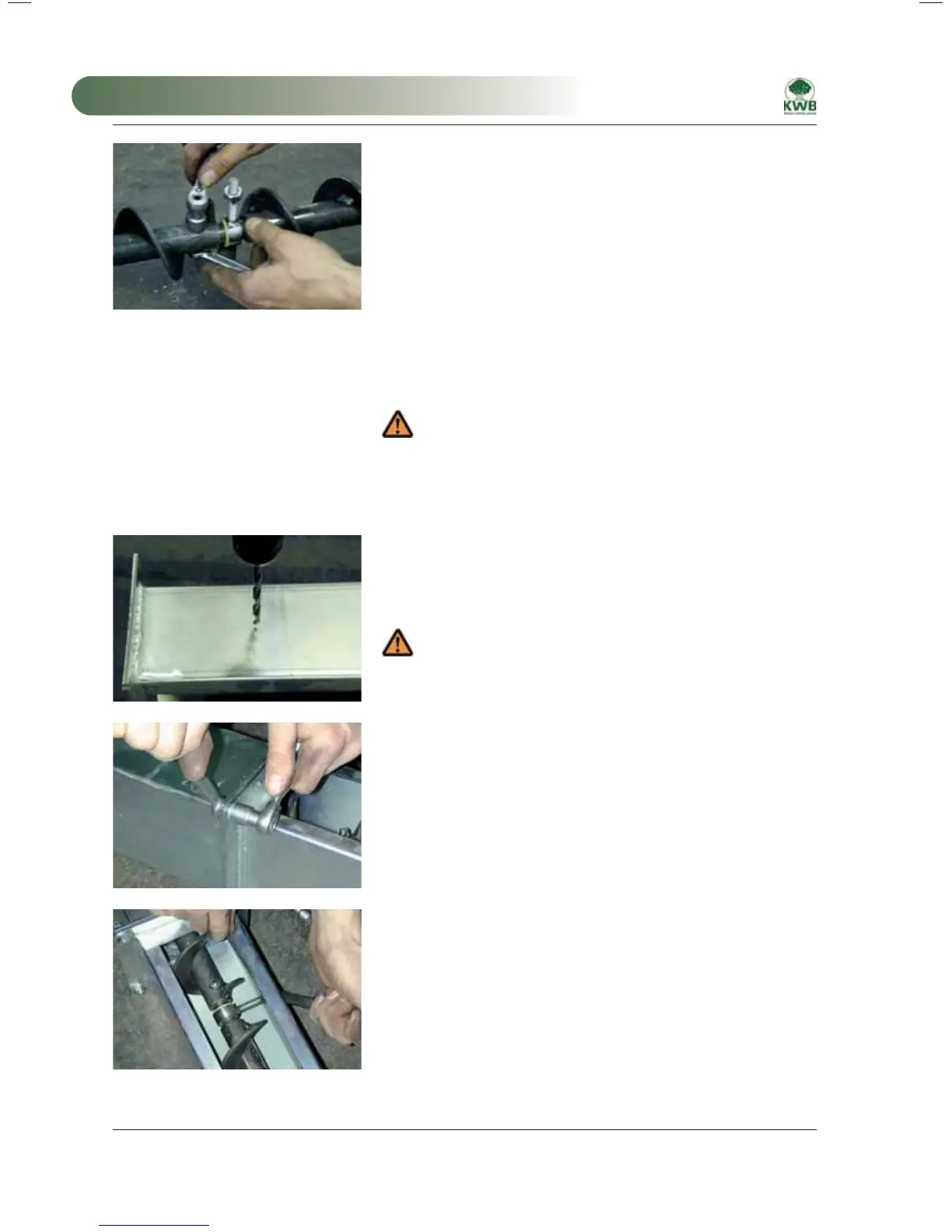

9.) Prepare the intermediate bearing

The trough extensions must be prepared for the intermediate bearing.

To do this enlarge the small bore in the side wall of the trough to

Ø 10 mm.

For extension KWB art. no. ZSV 24 place a second intermediate

bearing. (MBDK0001 in section 17)

Enlarge the bearing point bore

10.) Install the intermediate bearing

Guide the extension trough over the worm and bolt the two flanges

together

Connect the flanges

Guide the fastening bolts of the intermediate bearing through the

prepared bore of the side wall of the trough. Tighten the connection

and ensure that the bearing bush is in the aligned position. To do

this maintain the intermediate bearing at the appropriate position.

At this point a support is no longer necessary for the worm, as the ends

of the long worm elements are already permanently supported.

For additional extensions repeat the steps from step three. If there are

no additional extensions go to step 11.

Fasten the intermediate bearing

MA-Easyfire 10.2008_EN.indd 118MA-Easyfire 10.2008_EN.indd 118 30.03.2009 13:31:04 Uhr30.03.2009 13:31:04 Uhr

Loading...

Loading...