McHale Fusion 2 wrapper operation section

08- 4

McHale Fusion 2 round baler wrapper technical service manual

Issue 1: 0208

8.3 Wrapping process

The wrapping process starts automatically as soon as the bale has been transferred

from the bale chamber to the wrapping table (chamber door closed, rear roller in

fully raised position and the access door closed). After the bale is wrapped with the

selected number of film layers two cut & hold units grip and cut the film. The

wrapping cycle is completed and the bale is ready for discharging.

If ‘Auto Tip’ is selected the wrapped bale is discharged when netting of the

next bale starts.

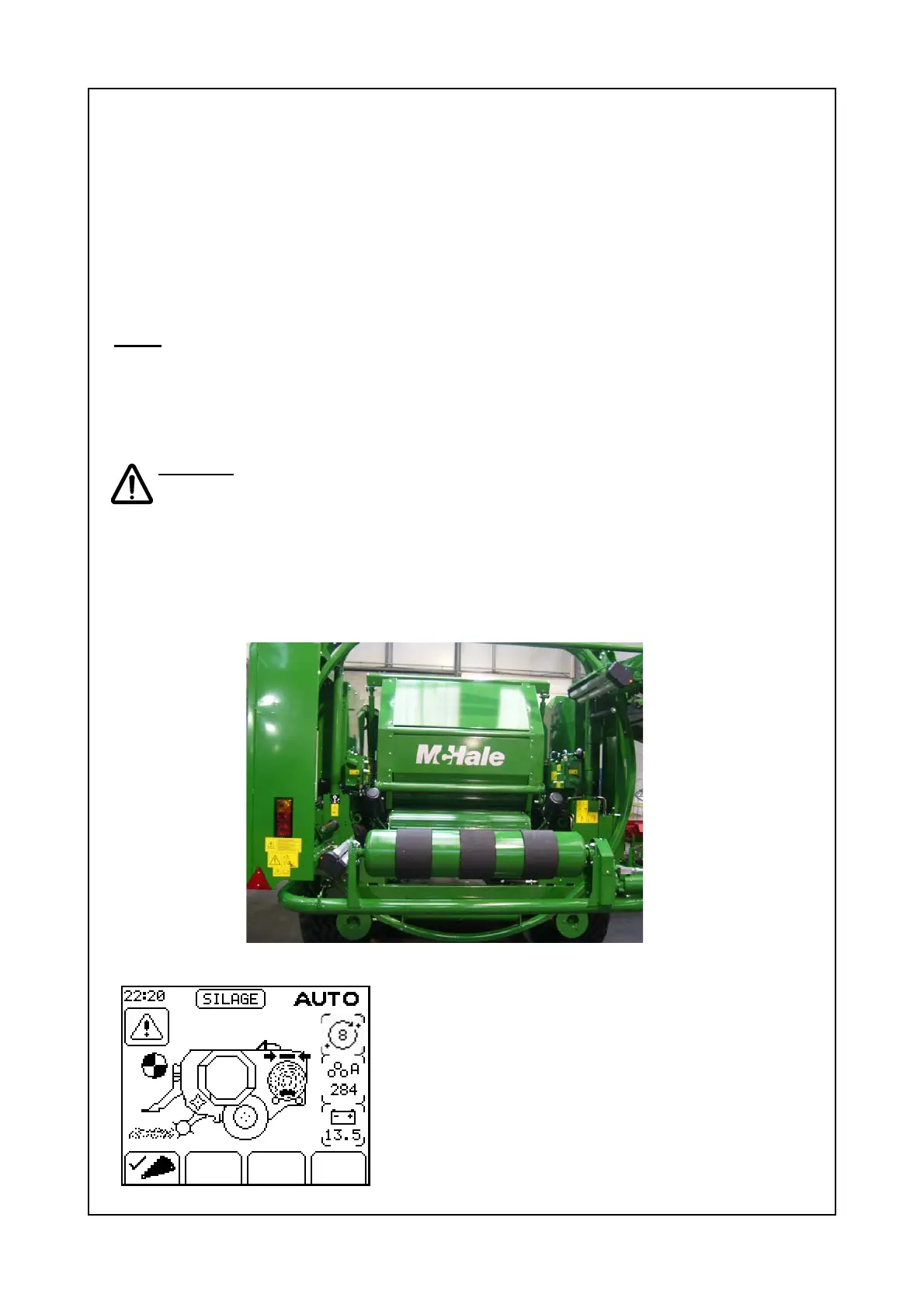

Note: The bale will not transfer from the baler chamber if the dispenser ring is in the

wrong position, this is a safety feature and is normal. In this case an audible alarm

will sound and “Dispenser Position” error symbol will be displayed in the control

box display. The forward and reverse soft key indicators will become active on the

control box. Press appropriate button in order to correct and once corrected the bale

will transfer and wrapping will start.

Caution! The machine should not be moving when the bale is tipped off, as

this greatly increases the risk of plastic film damage.

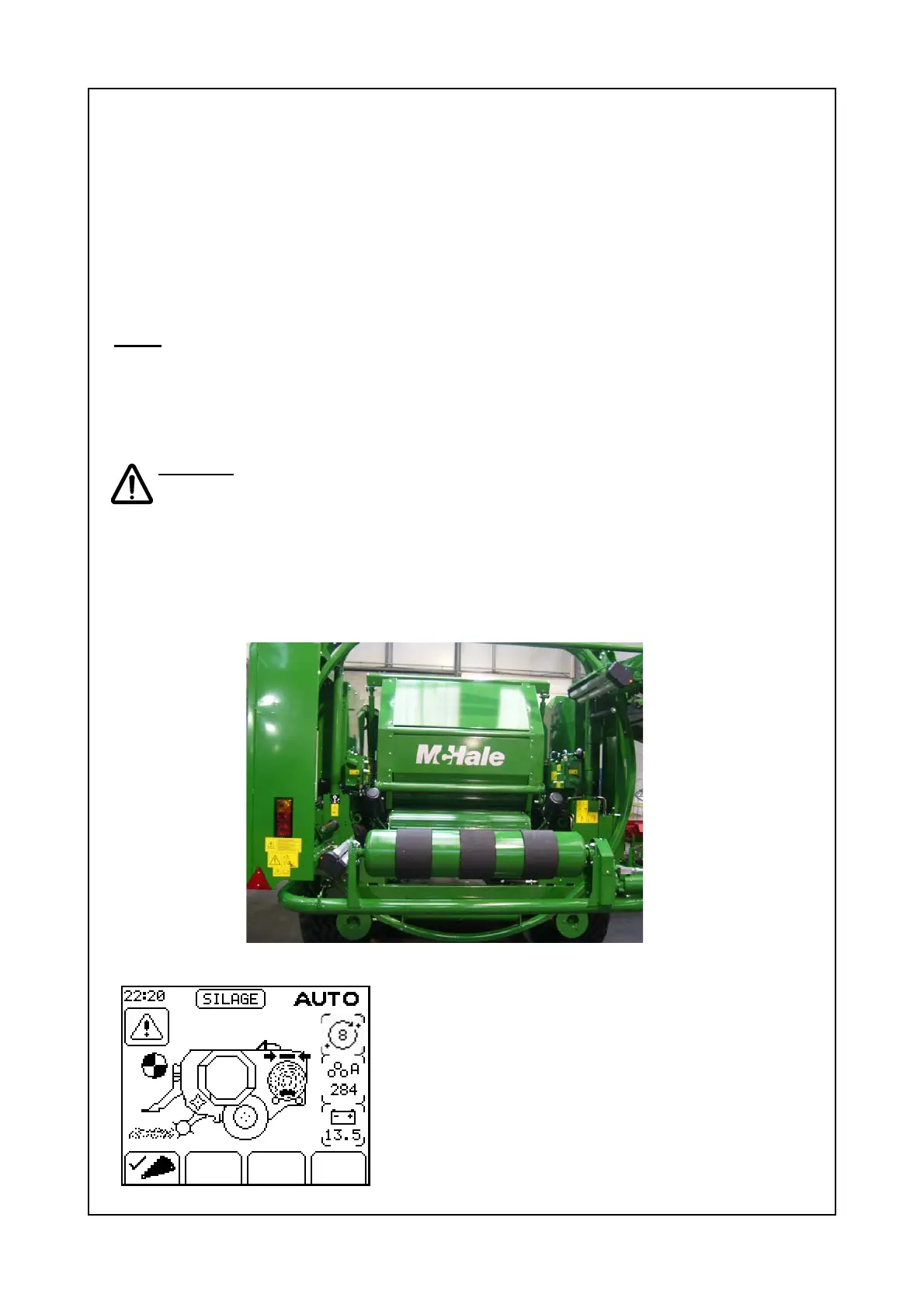

8.4 Dispenser adjustment

The dispenser rollers are set for a standard film stretch of 70%. Optional sets of

dispenser gears for both 55% and Enduro film streching are available from your

McHale dealer.

Figure 8.4.1 Dispenser in the "home" position.

Figure 8.4.2 Dispenser position error symbol

Loading...

Loading...