McHale Fusion 2 maintenance section

10-22

McHale Fusion 2 round baler wrapper technical service manual

Issue 1: 0208

10.6: Chain adjustments

It is important for the efficient operation of the machine that all drive chains are kept

correctly tensioned. The following is a general guide to chain adjustment.

The sag is measured at the midpoint of the chain between the sprockets.

Always ensure one side of the chain is tight so that the correct reading is obtained.

Even though some drives differ in detail the basic adjustments stay the same.

All roller chain adjustments will require two 19 mm spanners for adjustment, unless

otherwise stated. The following chains will

require an inspection for sagging after the first 500 bales and must be inspected

once per 1000 bales after this.

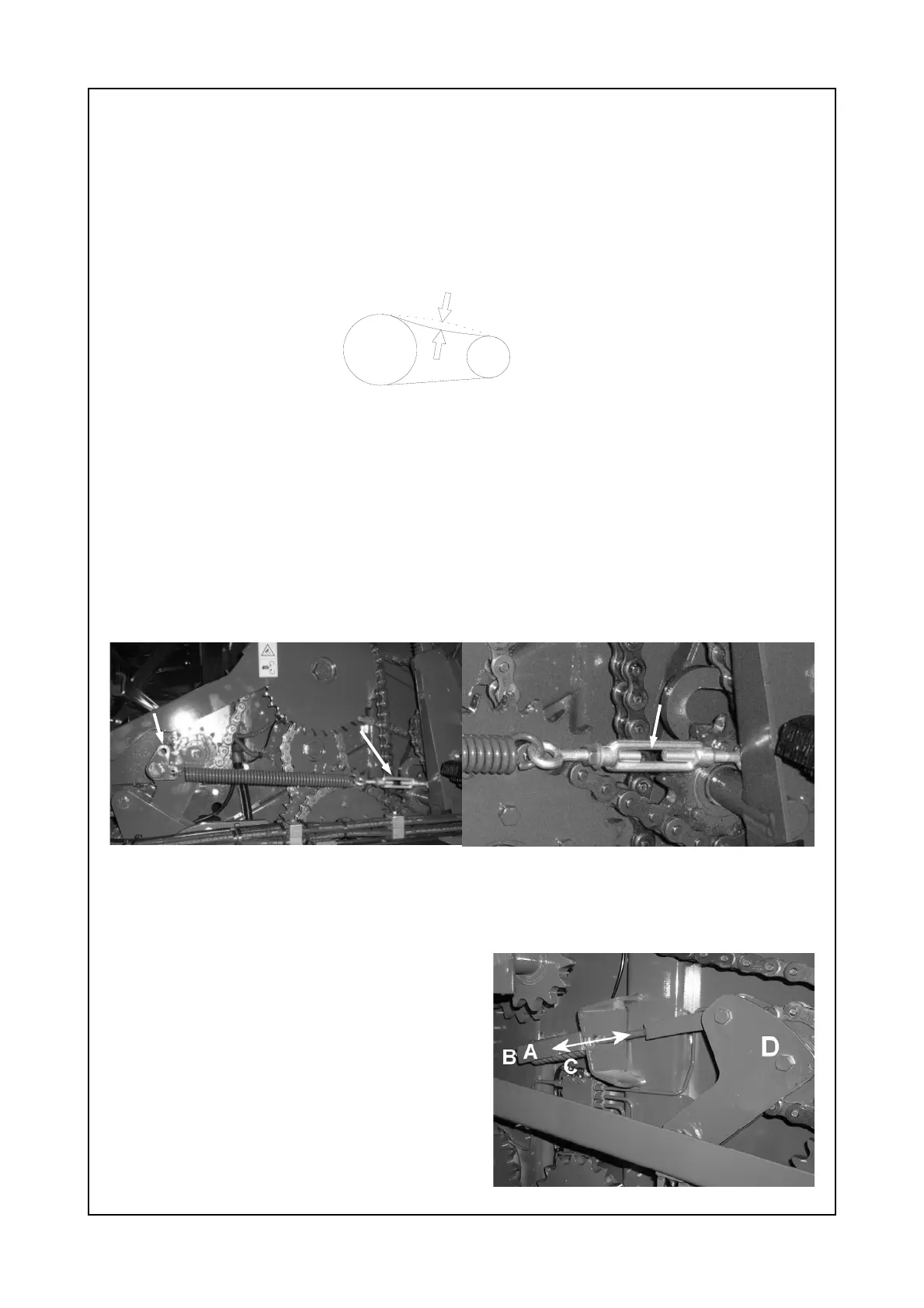

10.6.1: Main drive chain adjustment:

Adjust turn buckle (A) until the gap (D) is 25mm. As the chain wears the gap

(D) will need to be reduced. If there is no more adjustment available in the turn

buckle (A) the spring (B) can be moved to location (C) on the chain tensioner

bracket.

Always inspect chain tightness after adjustment.

SAG

10.6.2: Bottom chamber door chain adjustment:

Adjust M16 nyloc and nut (B) until com-

pression of spring (C) has reached the same

length as spring guide (A). Spring guide (A)

is an indicator only and

always inspect chain tightness after adjust-

ment, as greater spring compression may be

required, due to chain wear, chain damage

etc.

A

B

B

C

A

D

Loading...

Loading...