McHale Fusion 2 electronic control system section

11- 8

McHale Fusion 2 round baler wrapper technical service manual

Issue 1: 0208

11.2.8: PWM constant current module

Function

The Pulse Width Modulation constant current module is

connected between the control box and the proportional

hydraulic valve. It’s purpose is to stabilise the slow

speed against voltage and temperature variations.

It’s supplied with a constant 12 Volt supply and a

variable rotate PWM signal from the control box. It

monitors the current through the solenoid valve by a

sensing resistor in the ground circuit and keeps the

current through the valve at the desired level.

Testing

There is no simple test for the PWM module except by

substitution with a known good module.

However by referring to the forward rotate circuit

diagram the 12 Volt supply and rotate forward signal

can be checked.

Connections

1 = black, 2 = blue, 3 = yellow,

4 = red, 5 = white, 6 = green.

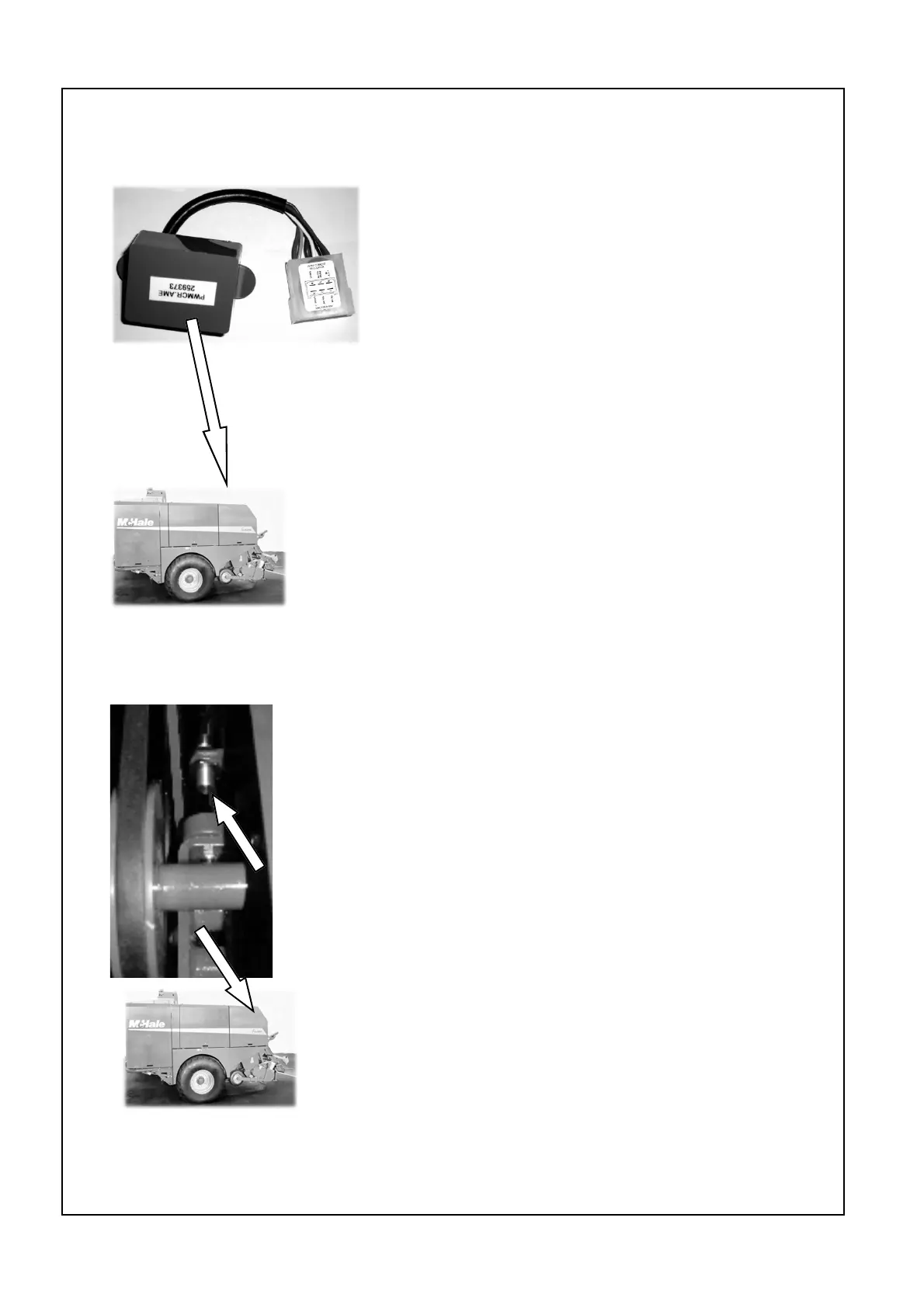

Function

The net cut sensor is a reed sensor that closes when the

net cut knife has tripped.

In an Auto cycle closing of the sensor triggers the transfer

part of the cycle.

If this sensor does not close within 20 seconds of the net

feed clutch energising it assumes that there is a net error

and it displays the ‘Net?’ error message on the control

box.

The net cut sensor must be closed to allow the transfer of

a bale.

Testing

This sensor can be monitored from within the Input/

Output test menu.

The sensor closes when a magnet is placed close to it’s

front face, less than 25 mm.

See Input/Output test section 11.8 and Sensor testing

section 11.4 .

11.2.9: Net Cut Sensor

Loading...

Loading...