McHale Fusion 2 field operation and adjustments section

9- 5

McHale Fusion 2 round baler wrapper technical service manual

Issue 1: 0208

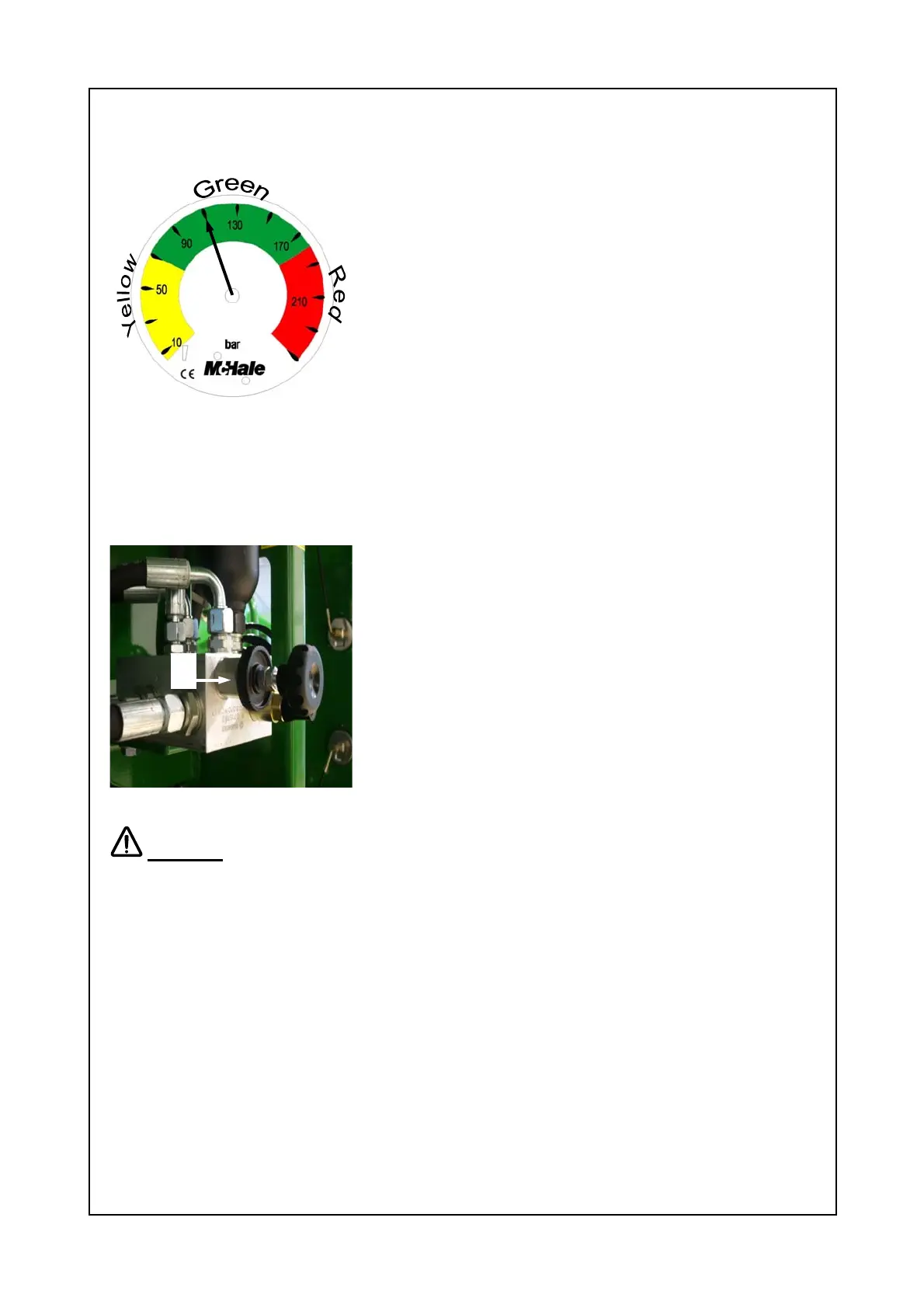

9.8 Bale density gauge

The bale density gauge, shown in figure 9.8.1 is used

to indicate the pressure applied to the top door rams

(on the small side of the rams).

When the top door is closed, and no material in the

baling chamber, this is known as “chamber

pre-charge pressure”. This pressure will then

increase at the end of the bale forming cycle due to

the oil in the cylinders being forced into the

accumulator, as material begins to fill up the baling

chamber, thus pushing the door rams open ever so

slightly. This can cause the gauge to go into the red,

and is normal operation. However, pressure should

never go above 210 bar, if so consult your McHale

dealer.

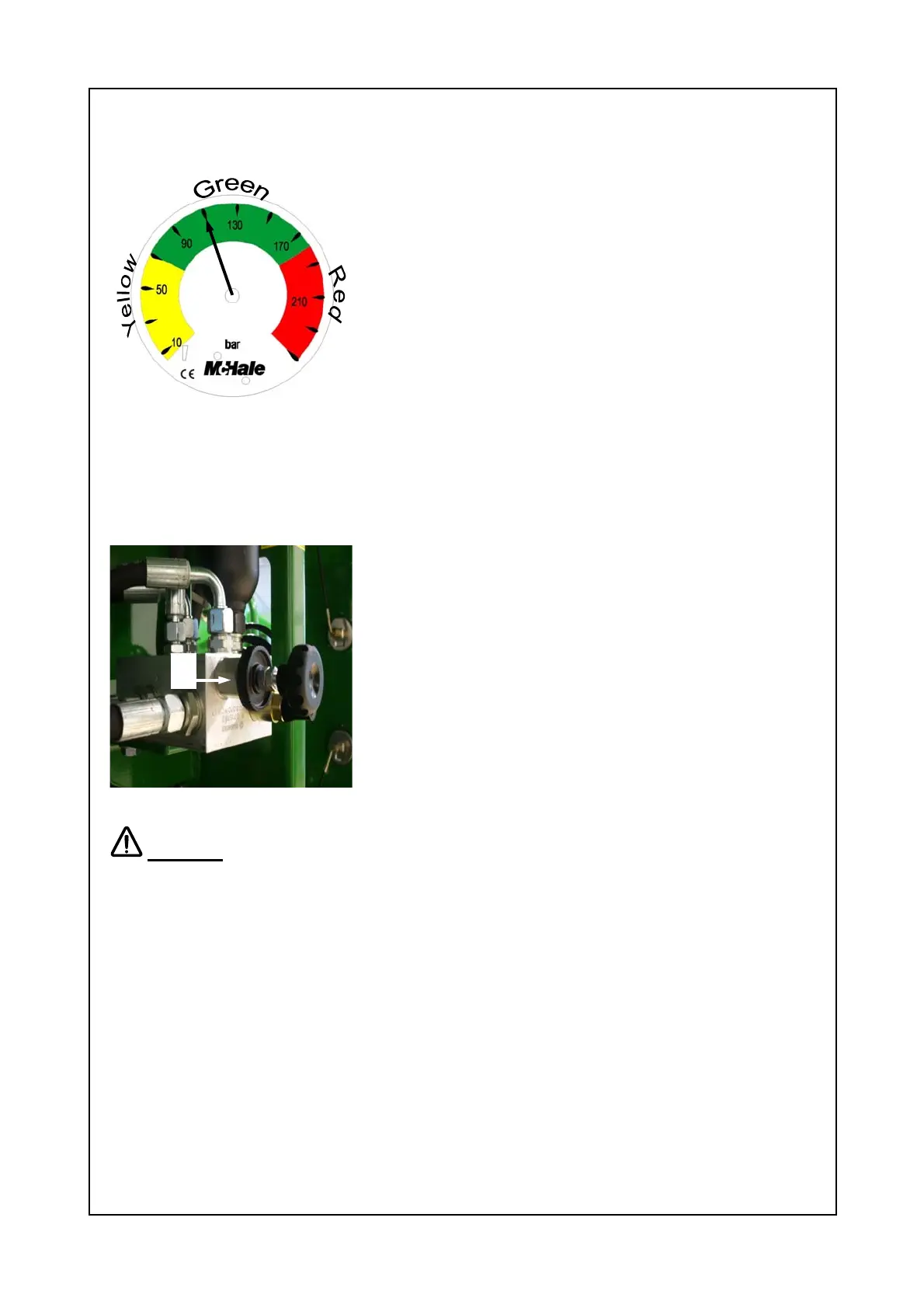

9.9 Setting chamber pre-charge pressure

The bale density gauge is divided up into increments

of 20 bar per increment and has a yellow zone, green

zone and a red zone as a quick reference during

machine operation. When baling drier materials such

as straw or hay McHale recommend setting the

chamber pre-charge pressure between 70 and 110 bar

pressure. When baling wetter materials such as grass

for silage a pressure of between 110 and 160 bar is

recommended. Chamber pre-charge pressure is set at

the door charge valve, shown in figure 9.9.1, and is

located in the hydraulic section (inside the front right

door panel) by following the below procedure.

Fig. 9.9.1 Door charge valve.

Caution:

The chamber pre-charge pressure should never be adjusted above

160 bar pressure in any case, damage to machine components may result!

1. Remove all unfinished and finished bales from the baling chamber.

2. Loosen the locking wheel on the adjustment screw (A).

3. Inspect the existing pre-charge pressure by holding the top door close button,

while in “manual” mode, on the control box for 3 seconds, see section 8 for

button referencing.

4. If pressure must be increased (gauge in the yellow zone, or if there is a change

in the material being baled i.e. dry to wet etc., gauge in the green zone) turn

the adjustment screw (A) clockwise and if the pressure is to be decreased turn

the adjustment screw anti-clockwise.

5. Continue to inspect the gauge and once the indicator needle is at the desired

setting, tighten the lock nut on the adjustment screw ensuring not to let the

adjustment screw itself rotate and close all protective covers. To reduce the

pressure the door must be opened, then turn the adjustment screw and close

the door again to check the gauge.

Fig. 9.8.1 Chamber pressure

A

Loading...

Loading...