Installation

1.

Apply Extreme Grease or 2‑4‑C with PTFE to the propeller shaft.

Tube Ref No. Description Where Used Part No.

Extreme Grease Propeller shaft 8M0071842

95

2-4-C with PTFE Propeller shaft 92-802859A 1

2. Install the front thrust hub onto the shaft so that the larger diameter end is facing the propeller.

3.

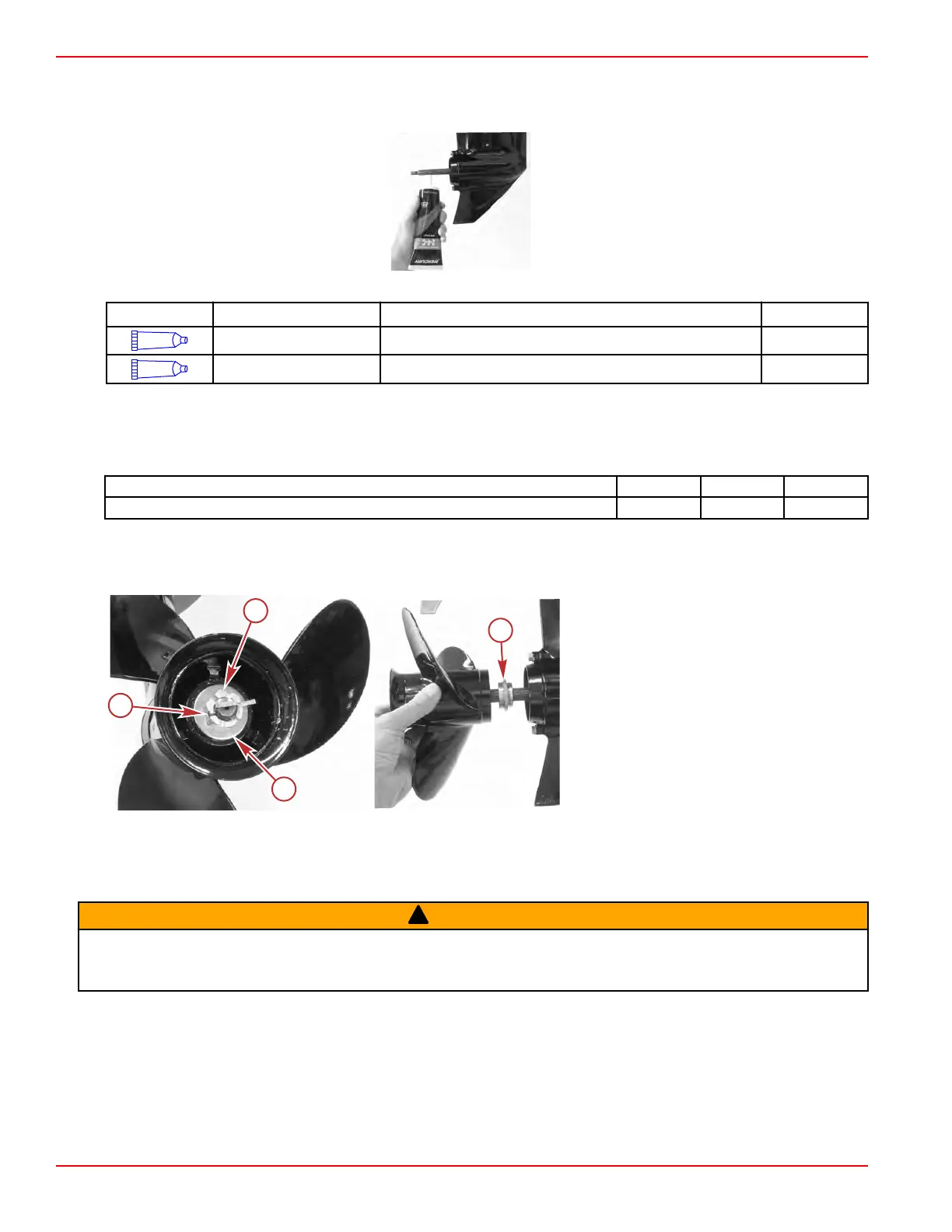

Install the propeller, rear thrust washer, and propeller nut onto the shaft.

4. Place a block of wood between the gearcase and the propeller to prevent rotation, and tighten the propeller nut to the

specified torque.

Description Nm lb‑in. lb‑ft

Propeller nut 12 106 –

NOTE: If the propeller nut does not align with the propeller shaft hole after tightening, tighten the nut further to align with

the hole.

5. Align the propeller nut with the propeller shaft hole. Insert a new cotter pin in the hole and bend the ends.

a - Cotter pin

b - Propeller nut

c - Rear thrust washer

d - Front thrust hub ‑ Larger diameter end

towards propeller

Gearcase Lubrication

Draining and Inspecting Gear Housing Lubricant

!

WARNING

Rotating propellers can cause serious injury or death. Never operate the boat out of the water with a propeller installed.

Before

installing or removing a propeller, place the drive unit in neutral and engage the lanyard stop switch to prevent the

engine from starting. Place a block of wood between the propeller blade and the anti‑ventilation plate.

Maintenance

Page 1B-14 © 2018 Mercury Marine 90-8M0125265 eng NOVEMBER 2017

Loading...

Loading...