2. CNC Monitor Screen

2.7 Diagnosis

I - 201

# Item Details

Setting

range

32 E-CONDITION

(Continued from the previous page)

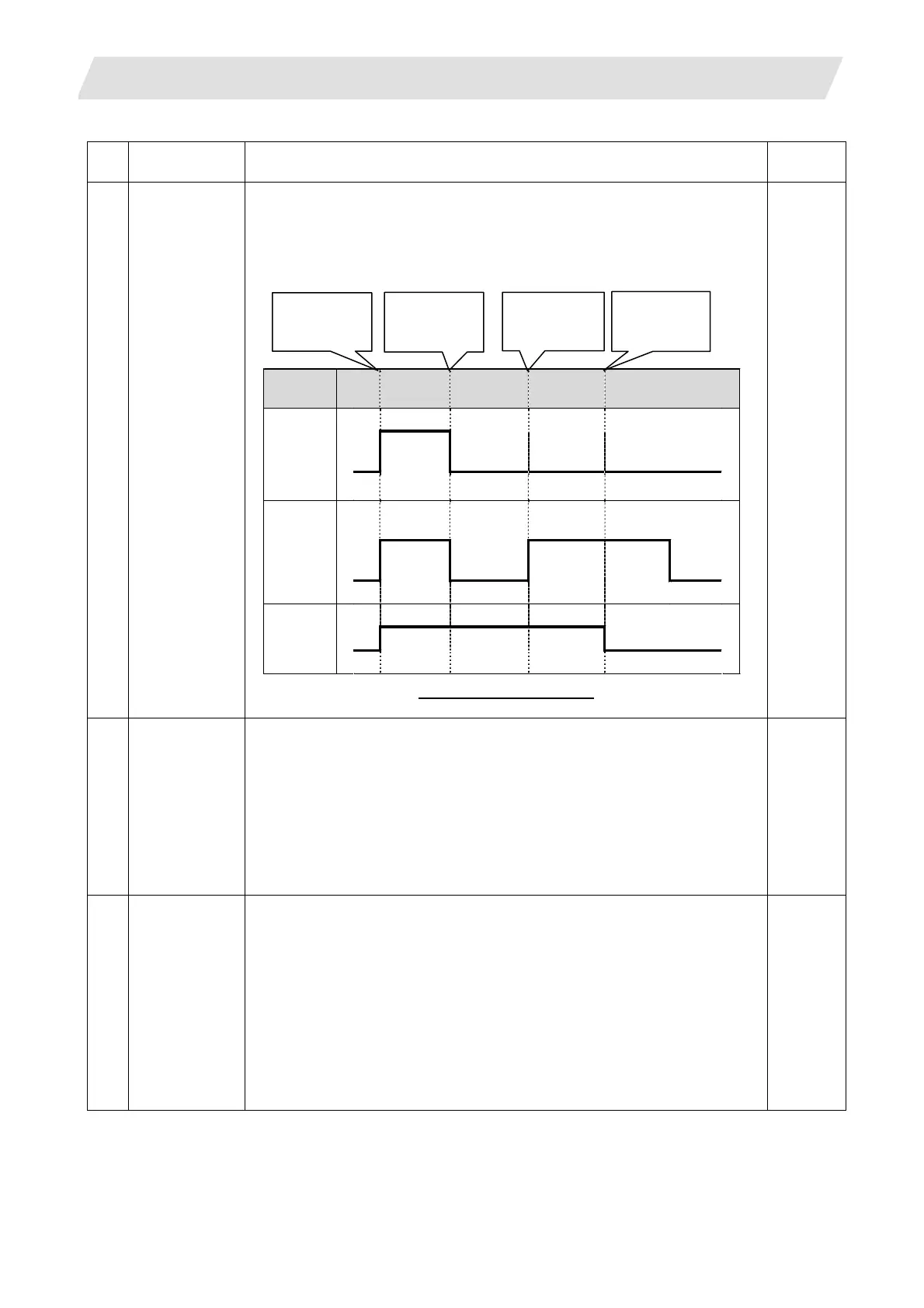

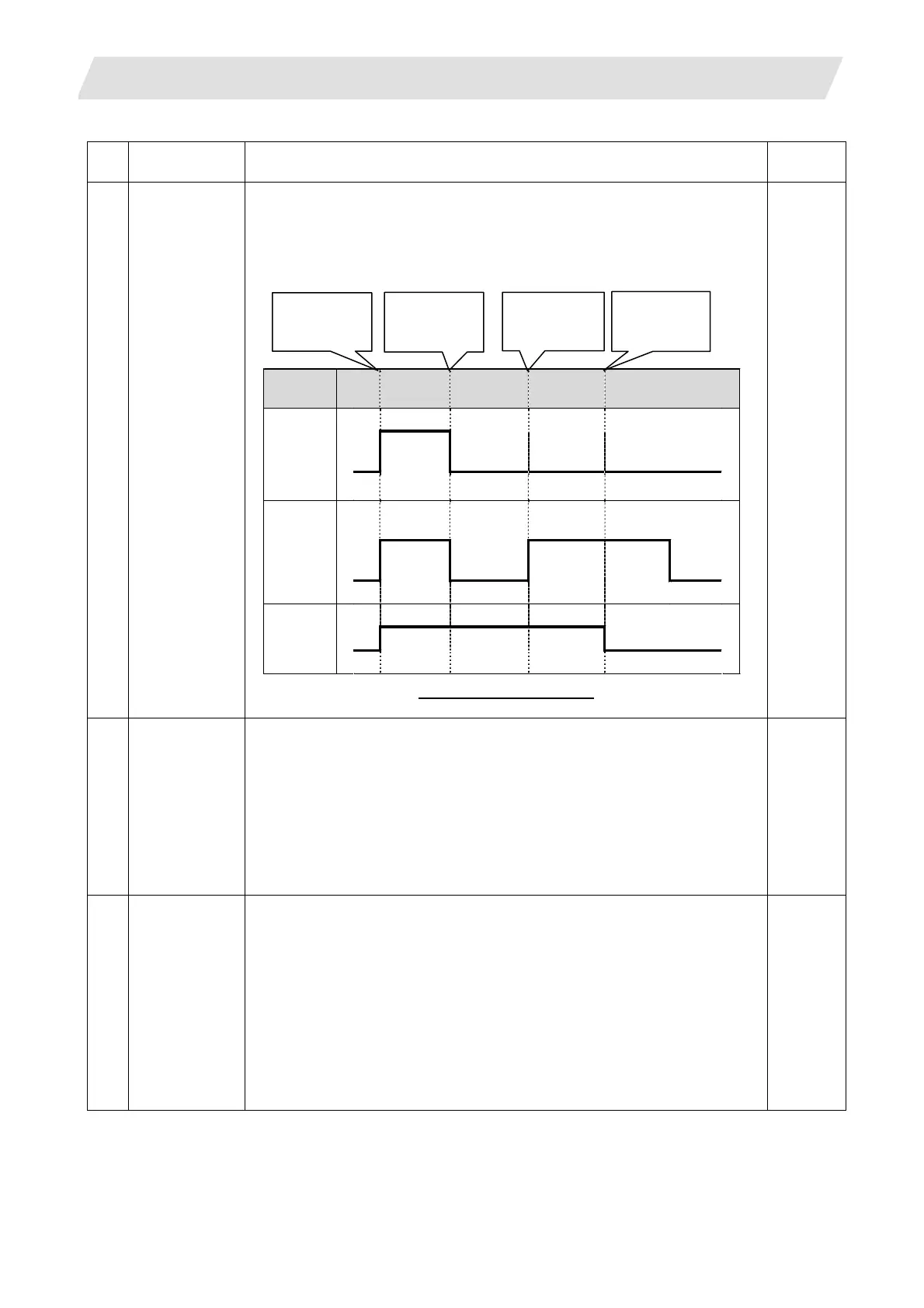

(Note 3) Even if the ending conditions are satisfied, the subsequent flow

will differ according to the value set in "#31 PROCESS FORM". Refer to

the following chart for details. (The chart is also applied when the

sampling is manually ended.)

PROCESS

FORM

Sampling Stop

sampling

One-shot

Process continued

until the buffer full

Sampling Waiting for

trigger

Sampling Ready to

stop

Stop

sampling

Repeat

Sampling Stop sampling

Ring

buffer

Start trigger

ON

End of

sampling

(Buffer full)

Start trigger

ON

End trigger

ON

Flow of sampling process

0 to 4

33 VARIABLE No.

Set the No. of a variable that triggers the start/end.

0: System variable (#1299)

Others: Designated common variable (#100 or later, #500 or later)

(Note 1) Setting #5 S-CONDITION" or "#32 E-CONDITION" to "1"

(variable No.) makes the variable set in this parameter trigger the

start/end.

(Note 2) "E02 DATA OVER" will occur when the entered No. does not

exist.

0 to 999

34 PLC DEVICE

Set the PLC device that triggers the start/end.

Add "

∗

" at the head of its No. to designate a normally closed contact device.

0(blank): Sampling start/stop signal (Y321)

Others: Designated device

(Note 1) Setting "#5 S-CONDITION" or "#32 E-CONDITION" to "2" (PLC

device) makes the device set in this parameter trigger the

start/end.

(Note 2) "E01 SETTING ERROR" will occur when the entered device No.

does not exist. "E02 DATA OVER" will occur when the No. is out

of the setting range.

(*)X0 to

XAFF

(*)Y0 to

YE7F

(*)B0 to

1FFF

Loading...

Loading...