87

安装 / 拆下刀具

MOUNTING/REMOVING TOOLS

6. 当拉出刀具时,准备一个及腰高的刀具支架以避免身体劳

损。用双手握住刀具直至其安装到主轴上。切勿单手或以笨

拙的姿势握住刀具。

[ 人身伤害 / 下腰痛 ]

6. Prepare a waist-height tool rack to avoid physical

strain when pulling the tool out. Keep holding the tool

with both hands until it is mounted in the spindle. Do

not hold the tool with one hand or in an awkward

posture.

[Injury/Lower back pain]

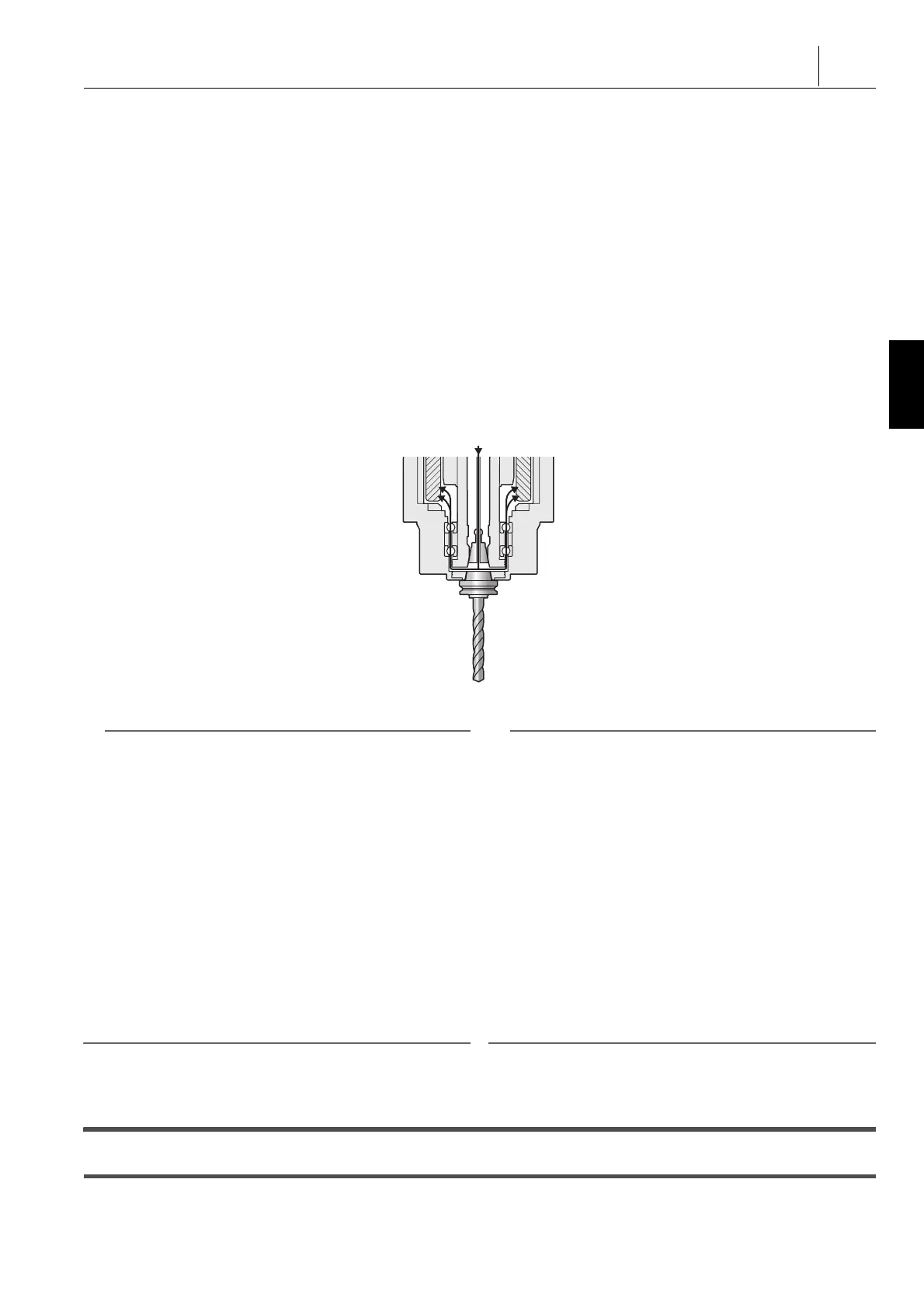

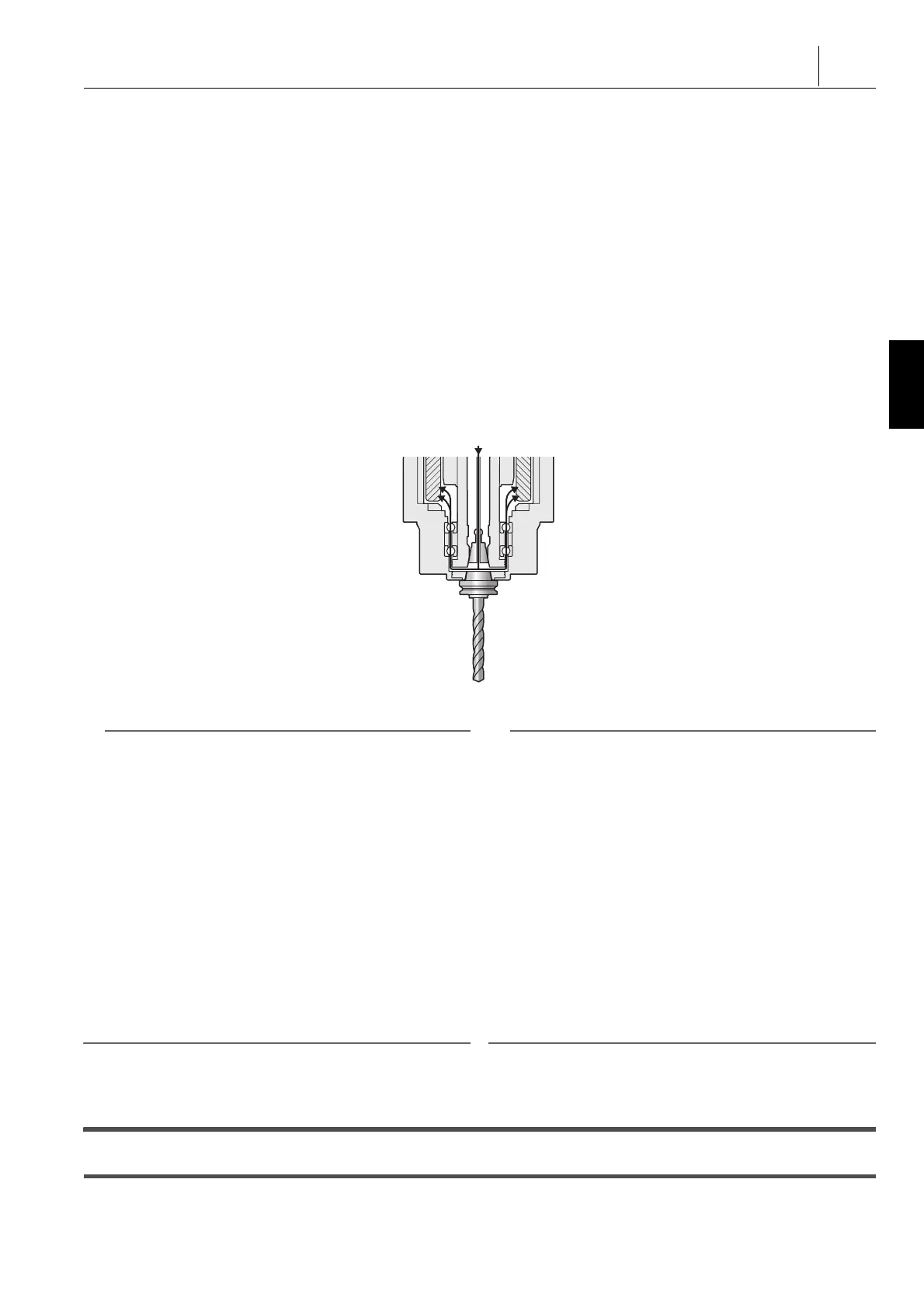

7. 对于贯穿主轴切削油规格,根据所使用的刀座型号,切削油

可能会进入主轴部件内。当选择刀座时,仔细考虑好刀座的

切削油油路。特别的,不能使用下列型号的刀座。

[ 机床损坏 ]

7. For the through-spindle coolant specifications, coolant

may enter the components of the spindle depending on

the type of tool holders used. When selecting tool

holders, carefully consider the coolant paths of the tool

holders. Particularly, the following types of tool

holders cannot be used.

[Machine damage]

< 在锥形部分有孔的刀座,例如舌形莫氏锥度刀座 > <Holders having holes in their tapered sections such

as the tongue type morse taper holder>

不要使用该型号的刀座。若使用了该刀座,切削油会通过刀

座上的孔进入主轴部件内。

Do not use tool holders of this type. If you do, coolant

enters into the components of the spindle through the

holes in the tool holder.

2 注意 2 NOTE

该图适用于中央贯穿主轴切削油规格。 The illustration is for the center through-spindle coolant

specifications.

< 锥形部分并不与主轴锥形部分完全接触的特殊刀座 > <Special holders whose taper section does not come

into a full contact with the spindle taper section>

不要使用该型号的刀座。若使用了该刀座,切削油会通过锥

形部分进入主轴部件内。

Do not use tool holders of this type. If you do, coolant

enters into the components of the spindle through the

taper section.

8. 对于配备贯穿主轴切削油系统的机床,应根据主轴规格确定

使用中央贯穿主轴型还是侧向贯穿主轴型供给方式的刀座。

[ 切削油排放故障,机床损坏 ]

8. For machines equipped with the through-spindle

coolant system, use tool holders corresponding to

either the center through-spindle type or side

through-spindle type supply method as determined by

the spindle specifications.

[Coolant discharge faulty, machine damage]

1 单独手册,安装手册“ 刀柄尺寸 ” 1 Separate volume, INSTALLATION MANUAL “ TOOL

SHANK DIMENSIONS ”

2 注意 2 NOTE

1. 当刀库门打开时,刀库不会旋转。 1. When the magazine door is open, the magazine will not rotate.

2. 在自动运行期间,不能手动操作旋转刀库。 2. The magazine cannot be rotated by manual operation during

automatic operation.

9-2 配有高速主轴机床的预防措施

Precautions for the Machine Equipped with High-Speed Spindle

对于配有高速主轴的机床(主轴轴承内径 (mm) × 主轴转速

(min

−1

) ≥ 1.2 万),请遵守以下预防措施。

For the machine equipped with a high-speed spindle (spindle

bearing I.D. (mm) × spindle speed (min

−1

) ≥ 1.2 million),

observe following precautions.

Loading...

Loading...