安装 / 拆下刀具

MOUNTING/REMOVING TOOLS

88

8 警告 8 WARNING

1. 某些情况下,受夹具和刀具所限,即使刀具的长度、直径和

质量在限制范围之内,主轴也不能在指定的最高转速下旋

转。在这种情况下,不应强制主轴在高速下旋转。

[ 切削刀具会飞出,导致严重伤害或机床损坏 ]

1. There are cases that the spindle must not be rotated at

the specified maximum speed due to the conditions of

the jig and the cutting tools, even if the length, the

diameter, and the mass of the cutting tool are within

the restrictions. The spindle should not be forcibly

rotated at a high speed in such cases.

[Cutting tool could fly out, causing serious injuries or

damage to the machine]

2. 当在 15000 min

−1

或更高的主轴高速下操作机床时,使用双

面约束刀座。

[ 使用其它刀座,则可能无法松开刀具。*]

2. When operating the machine at a high spindle speed,

15000 min

−1

or higher, use two-face constrained tool

holders.

[With other tool holders, it may be impossible to

unclamp the tool.*]

2 注意 2 NOTE

* 主轴高速旋转时,由于离心力作用,夹紧刀座的主轴锥度区域会

更大。当使用了非双面约束型刀座时,刀座会卡在主轴锥度区域

的扩大部分,导致主轴停止后,很难将其从主轴上拆下。

* Rotating the spindle at high speed cause the spindle taper area

clamping the tool holder to enlarge affected by the centrifugal

force. When a tool holder other than two-face constrained type is

used, it could be drawn to the spindle taper area where

enlarged, causing difficulty in removing it from the spindle when

it stops.

7 小心 7 CAUTION

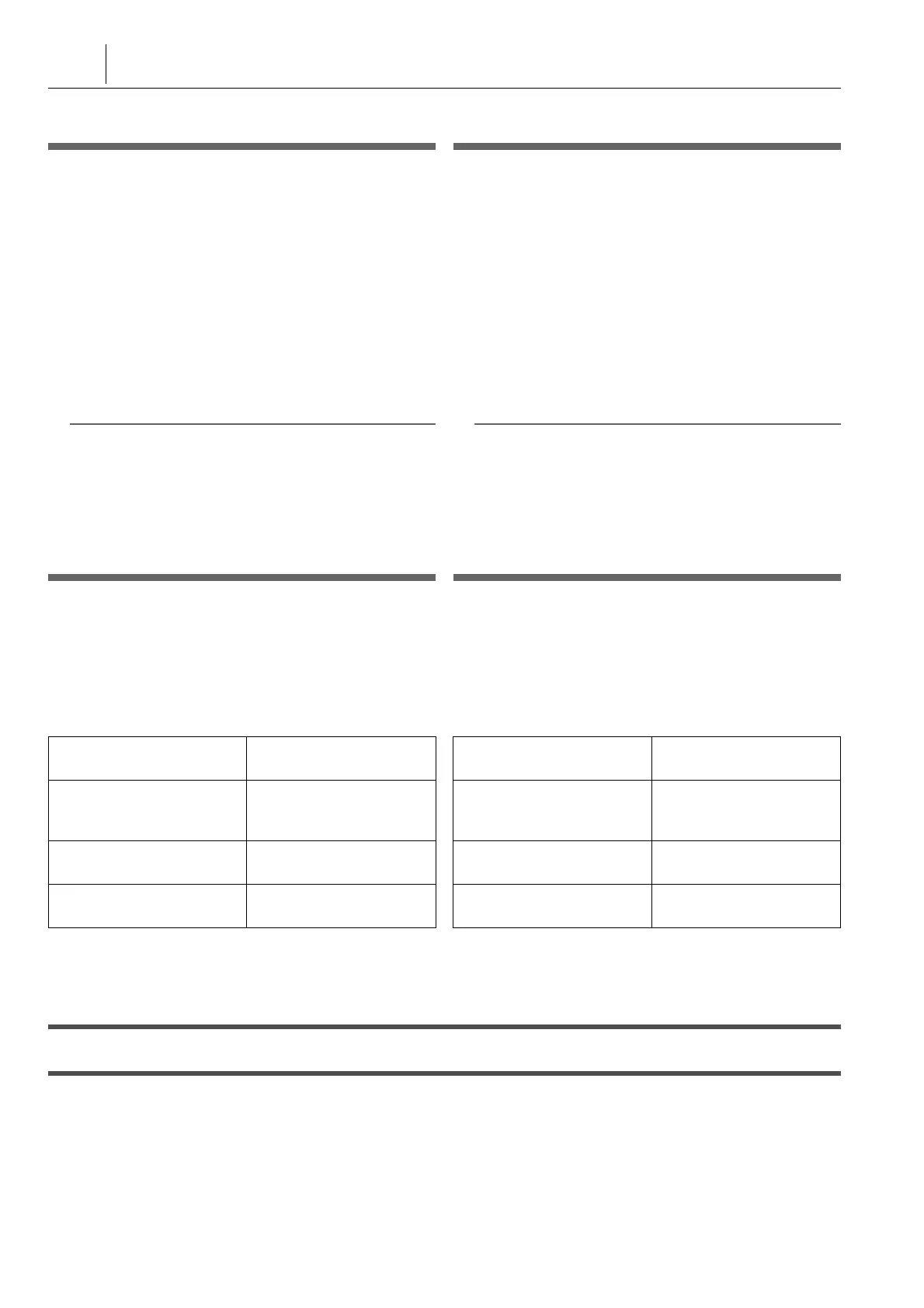

1. 切削刀具高速旋转时的动态失衡会引起机床振动,导致轴承

快速损坏和切削刀具过度磨损,对机床和精度造成不良影

响。因此,高速主轴使用的切削刀具,其所许容的失衡应在

以下的限制范围内。

[ 对机床或加工精度的不良影响 ]

1. High speed rotation of a cutting tool that has dynamic

imbalance will cause machine vibration, adversely

affecting the machine and accuracy by damaging the

bearing quickly and wearing cutting tool excessively.

Therefore, the allowable imbalance for the cutting tool

used in the high-speed spindle should be within the

following restrictions.

[Adverse effect on the machine or machining accuracy]

2. 为确保轴承寿命,执行主轴预热操作。 2. To ensure bearing life, perform spindle warm-up

operation.

1 单独手册,保养手册“ 主轴预热 ” 1 Separate volume, MAINTENANCE MANUAL “ Spindle

Warm-Up ”

9-3 安装刀具

Mounting Tools

< 安装刀具时的检查项目 > <Check Items when Mounting Tools>

1. 安装前要清洁刀座和切削刀具。 1. Tool holders and cutting tools are cleaned before mounting.

2. 刀座的锥形面无划痕或表面粗糙。 2. The tapered surface of the tool holder has no scratches or

asperities.

3. 切削刀具应避免异常磨损和破损。 3. Cutting tools are free of abnormal wear and breakage.

4. 刀具形状和材质要适合于将要进行的操作。 4. Tool shape and material are appropriate for intended

operation.

HSK-E32 使用 60000 min

−1

时

0.5g•mm

(包括切削刀具)

HSK-E32 使用 40000 min

−1

时

, HSK-F63 使用 30000 min

−1

时

1 g•mm

(包括切削刀具)

BT-40、HSK-A63 使用 20000

min

−1

时

3 g•mm

(包括切削刀具)

BT-50、HSK-A100 使用 10000

min

−1

时

3 g•mm

(包括切削刀具)

HSK-E32 used at

60000 min

−1

0.5g•mm

(including cutting tool)

HSK-E32 used at

40000 min

−1

, HSK-F63 used

at 30000 min

−1

1 g•mm

(including cutting tool)

BT-40, HSK-A63 used at

20000 min

−1

3 g•mm

(including cutting tool)

BT-50, HSK-A100 used at

10000 min

−1

3 g•mm

(including cutting tool)

Loading...

Loading...