创建程序

CREATING PROGRAM

112

15 创建程序

CREATING PROGRAM

15-1 程序创建步骤

Program Creation Procedure

1) 图纸 1) Drawing

a) 研究夹具和装夹方法。 a) Study the fixture and clamping method.

b) 确定加工方法和选刀。 b) Determine the machining method and tooling.

c) 确定工件零点。 c) Determine the workpiece zero point.

2) 创建一个工序卡 2) Creating a process sheet

a) 考虑加工顺序。 a) Consider the machining order.

b) 确定切削条件(主轴转速、切削深度、进给速度等),

并按照以下规则创建一个工序卡。

b) Determine the cutting conditions (spindle speed, depth

of cut, feedrate etc.) and create a process sheet

following the rules.

3) 创建程序 3) Creating the program

< 工序卡 > <Process Sheet>

15-2 工件零点

Workpiece Zero Point

编程基准点称为工件零点 (X0 , Y0 , Z0 , B0 , C0)。 The reference point for programming is called the workpiece

zero point (X0, Y0, Z0, B0, C0).

精确研究图纸,然后确定零点以利于编程、装夹以及达到所需

精度。

Study the drawing precisely, and then determine the zero point

that can facilitate the programming and setup and allow the

required accuracy.

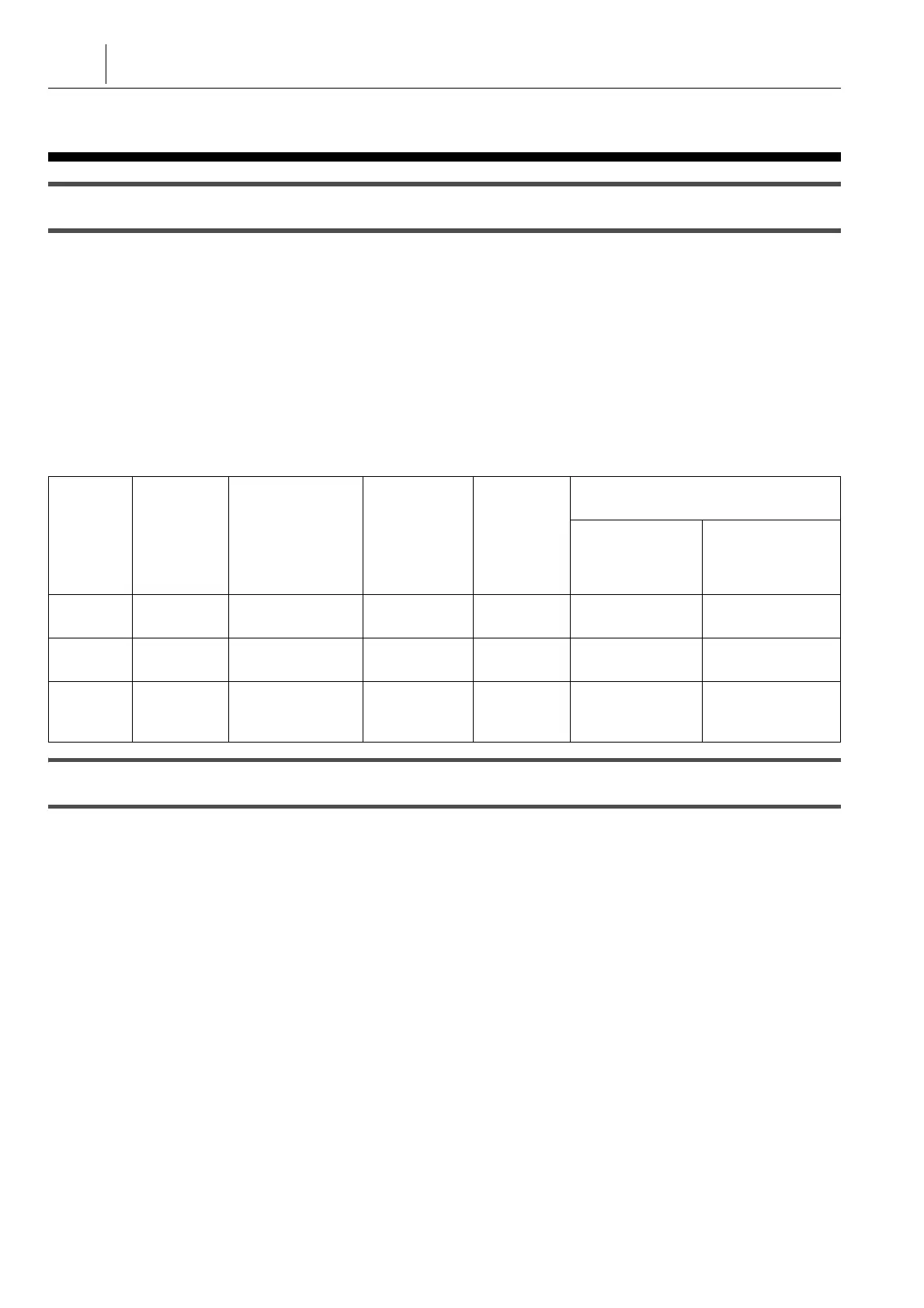

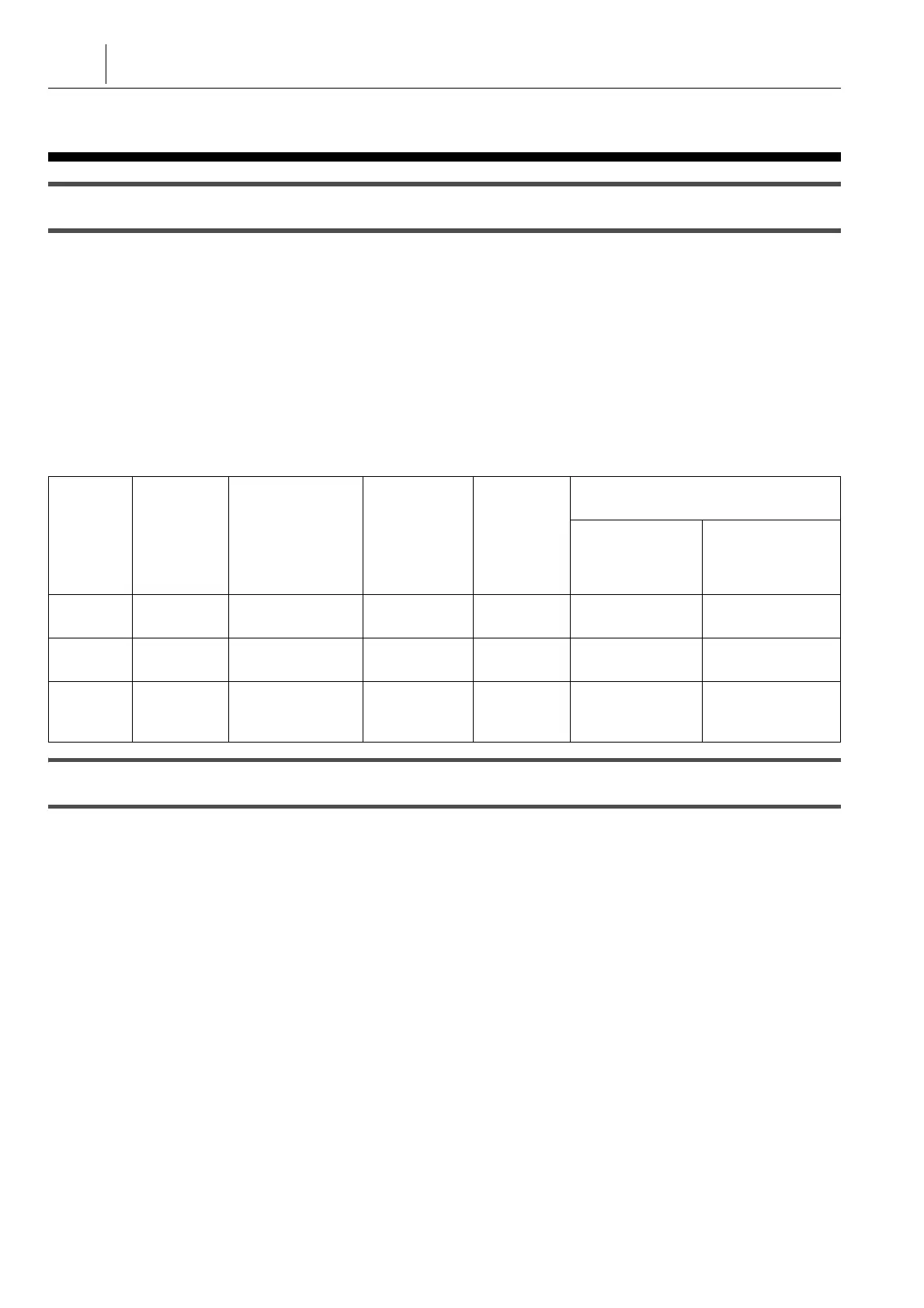

工序

Process

刀具编号 (T)

Tool Num-

ber (T)

刀具名称

Tool Name

主轴转速 (S)

Spindle

Speed (S)

(min

−1

)

进给速度 (F)

Feedrate (F)

(mm/min)

偏移编号

Offset Number

刀具长度偏移编号

(H)

Tool Length Off-

set Number (H)

刀具半径偏移编号

(D)

Tool Radius Off-

set Number (D)

N1 1

中心钻

Center drill

1500 100 1 —

N2 2

6 mm 直径钻头

6 mm dia. drill

1000 150 2 —

N3 3

20 mm 直径铣刀

20 mm dia. end

mill

300 60 3 3

Loading...

Loading...