Troubleshooting

7-2

Part 1602966−05

E 2015 Nordson Corporation

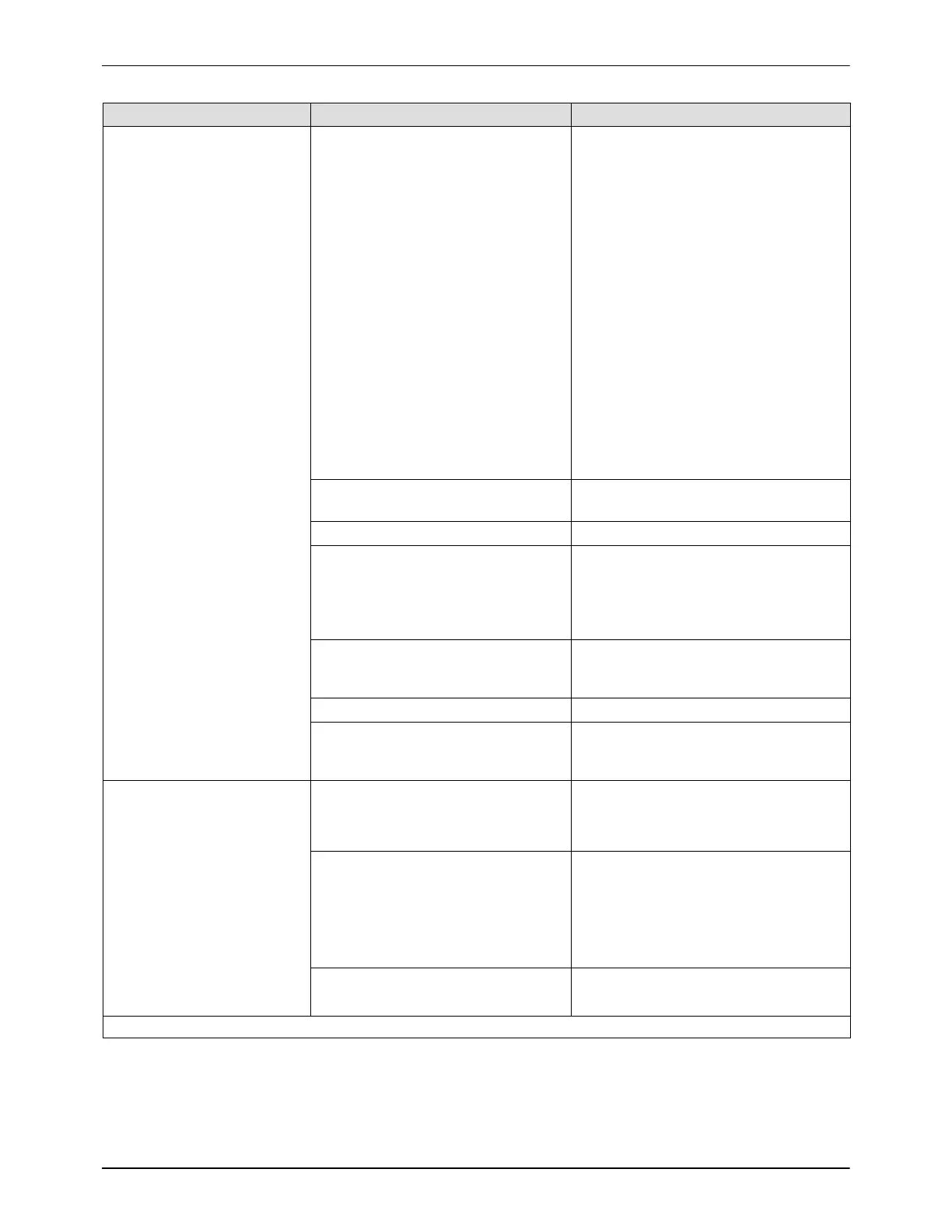

Corrective ActionPossible CauseProblem

2. Powder escaping

from enclosure

openings

Afterfilter cartridge filters clogged;

pulsing not cleaning filters

Pulse the cartridge filters to blow off

powder.

Check the pulse air pressure.

Check the cartridge filter pulse

sequence:

S If the Off duration is too short, the

pulse manifold may not build up

enough pressure to blow off the

cartridge filters.

S If the On duration is too short, not

enough air is released to blow off

the filters.

S If the On duration is too long, the

pulse manifold may not be able to

build up enough air pressure.

Replace the cartridge filters if pulsing

does not correct the problem.

Pulse pressure too low Increase the pulse pressure to the

recommended level.

Pulse valve failed Replace the pulse valve.

Cartridge filters leaking Check the cartridge filter gaskets and

media for damage. Tighten the

mounting nut to compress the

gaskets. Replace filters as

necessary.

Cross drafts interfering with

exhaust fan draw

Check for cross drafts at the

enclosure opening. Eliminate or

divert drafts.

Fan rotation backward Reverse the motor rotation.

Access panels not sealed Tighten all access panels. Check and

replace the panel gaskets as

necessary.

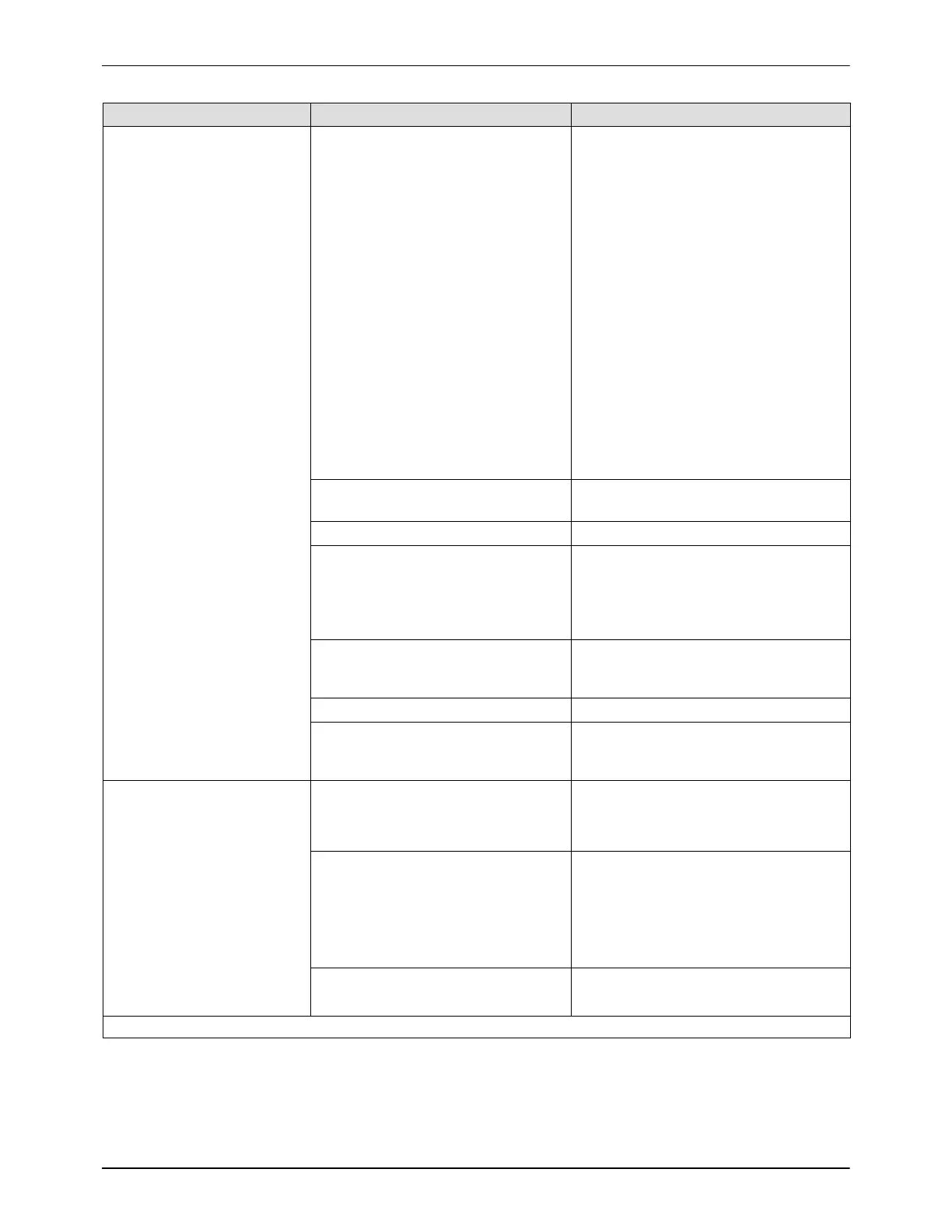

3. No feed hopper

fluidizing air

Afterfilter fan not running, interlock

valve closed

Start the afterfilter exhaust fan.

Check feed center E-Stop.

Check valve connections.

Fan interlock circuit or solenoid

valve circuit defective

Check the fan interlock wiring

between the feed center panel and

main system panel.

Check the wiring from the feed center

panel to the solenoid valve assembly

on top of the feed center air drop.

Fluidizing air regulator defective Check the fluidizing air regulator.

Continued...

Loading...

Loading...