Troubleshooting

7-3

Part 1602966−05

E 2015 Nordson Corporation

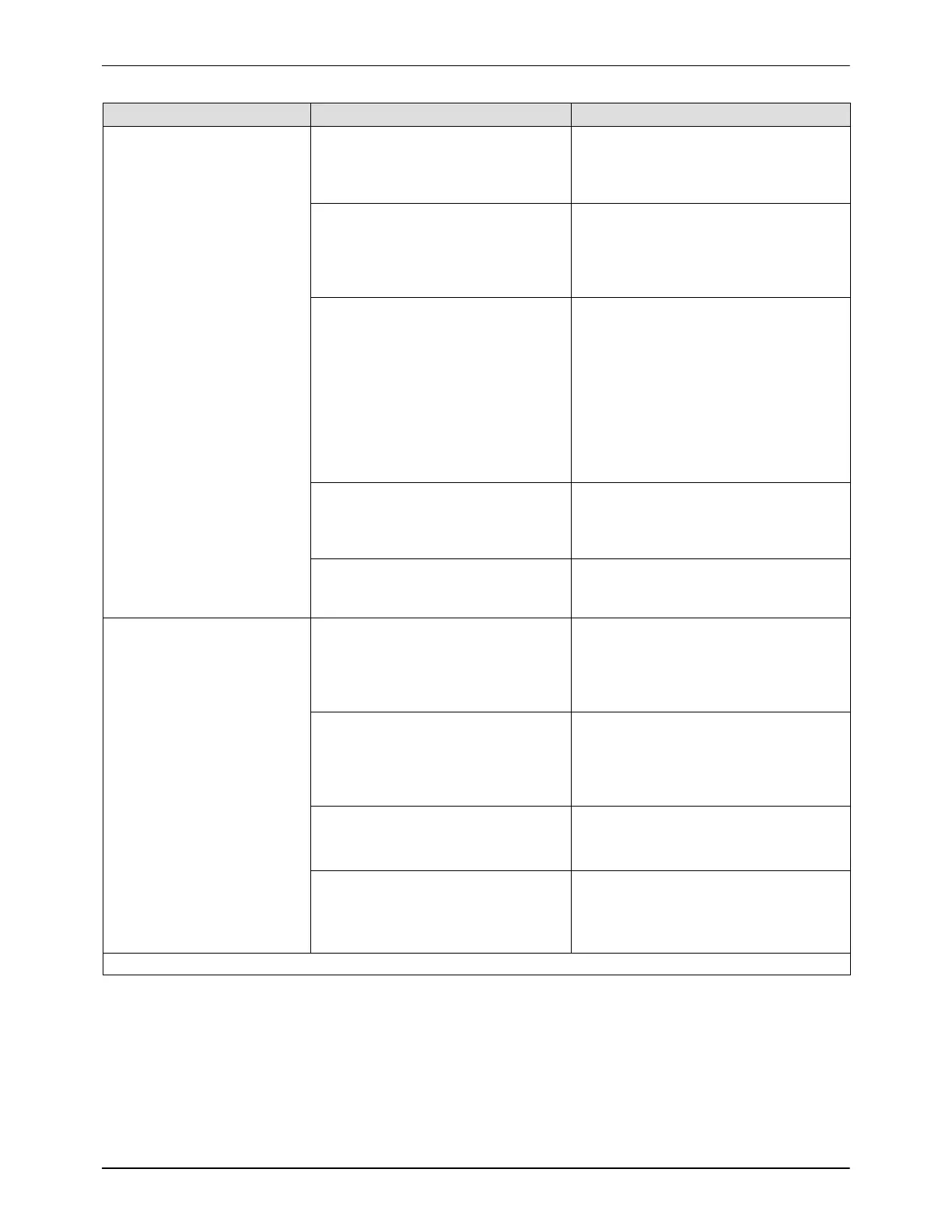

Corrective ActionPossible CauseProblem

4. Powder in feed

hopper not fluidizing,

or clouds of powder

erupting from surface

Fluidizing air pressure too low or

too high

Increase the fluidizing air pressure

until the powder is gently boiling.

Decrease the pressure if clouds of

powder are erupting from the surface.

Moist or oil-contaminated powder Check the air supply for water or oil.

Check the filters, separators, and air

dryer. Replace the powder in the

feed source if it is contaminated.

Refer to the next possible cause.

Fluidizing plate gasket leaking, or

fluidizing plate plugged, cracked,

or installed incorrectly

Check for air leaks around the

fluidizing plate gasket. If leaks are

found, replace the gasket.

Inspect the fluidizing plate for stains,

discoloration, polished surfaces, or

cracks. Replace it if contaminated,

plugged, or damaged. The plate

should be installed with the smooth

surface up (in contact with the

powder).

Incorrect ratio of reclaimed to virgin

powder

Increase or decrease the transfer

rate. The powder supply should be

no more than three parts reclaim to

one part virgin powder.

Uneven distribution of powder in

feed source

Check the powder and the fluidizing

plate for contamination as previously

described.

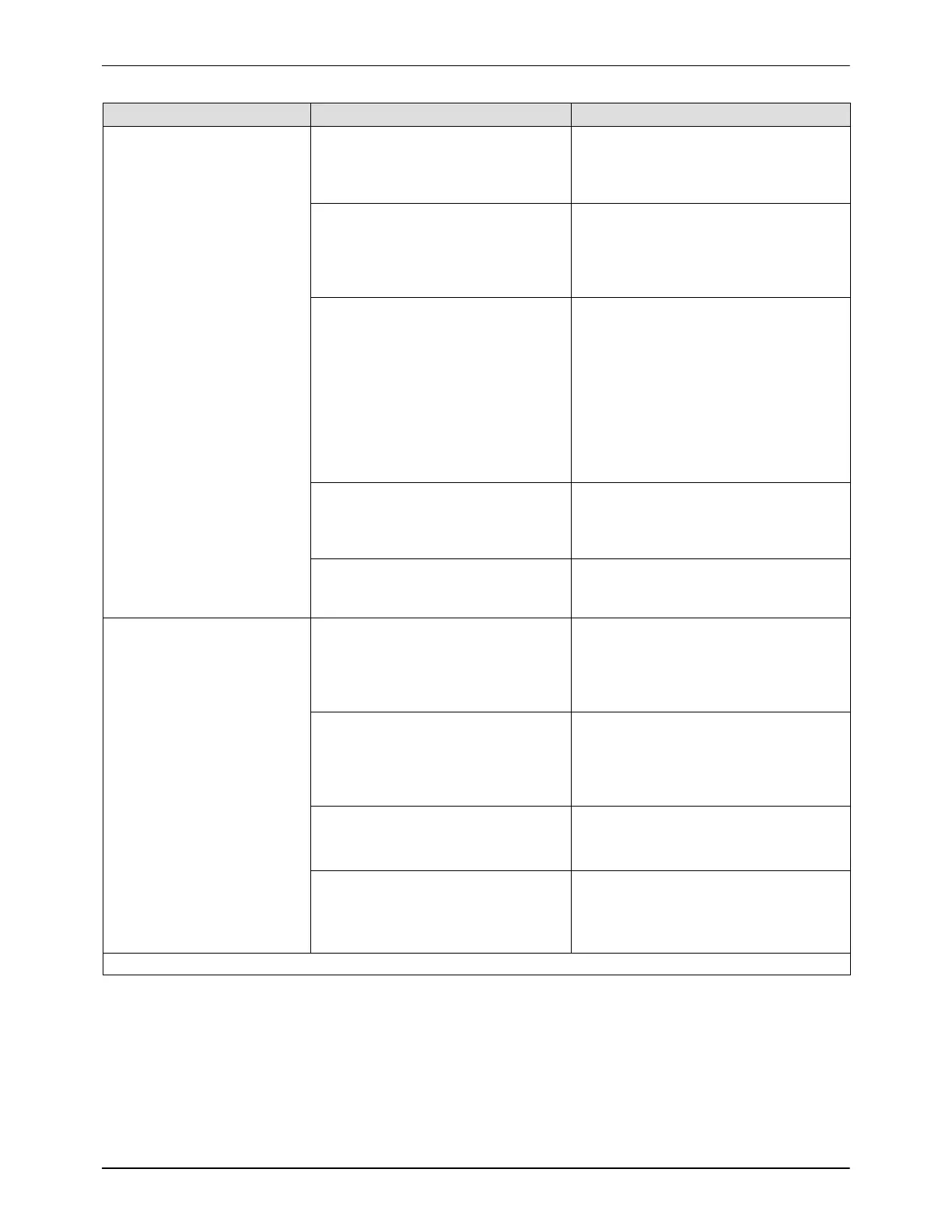

5. Powder in box not

fluidizing, or clouds

of powder erupting

from surface

Lance fluidizing air pressure too

low or too high

Increase the lance fluidizing air

pressure until the powder is gently

boiling. Decrease the pressure if

clouds of powder are erupting from

the surface.

Moist or oil-contaminated powder Check the air supply for water or oil.

Check the filters, separators, and air

dryer. Replace the box if the powder

is contaminated. Refer to the next

possible cause.

Fluidizing bar assembly leaking or

damaged

Raise the lance assembly and check

the fluidizing bars.

Vibratory table motor defective Check the vibrator motor. Refer to

Problem 6 for motor troubleshooting

procedures.

Continued...

Loading...

Loading...