Troubleshooting

7-4

Part 1602966−05

E 2015 Nordson Corporation

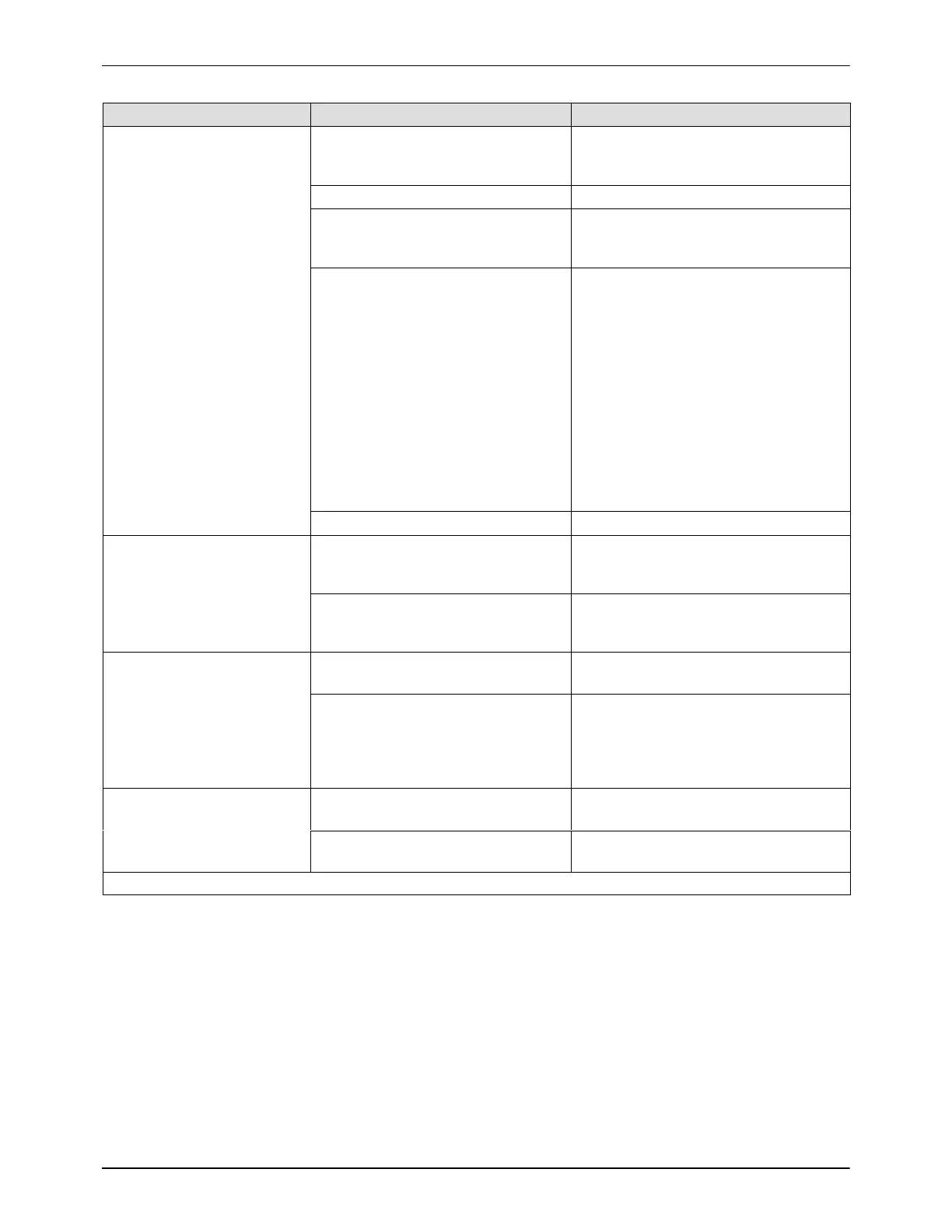

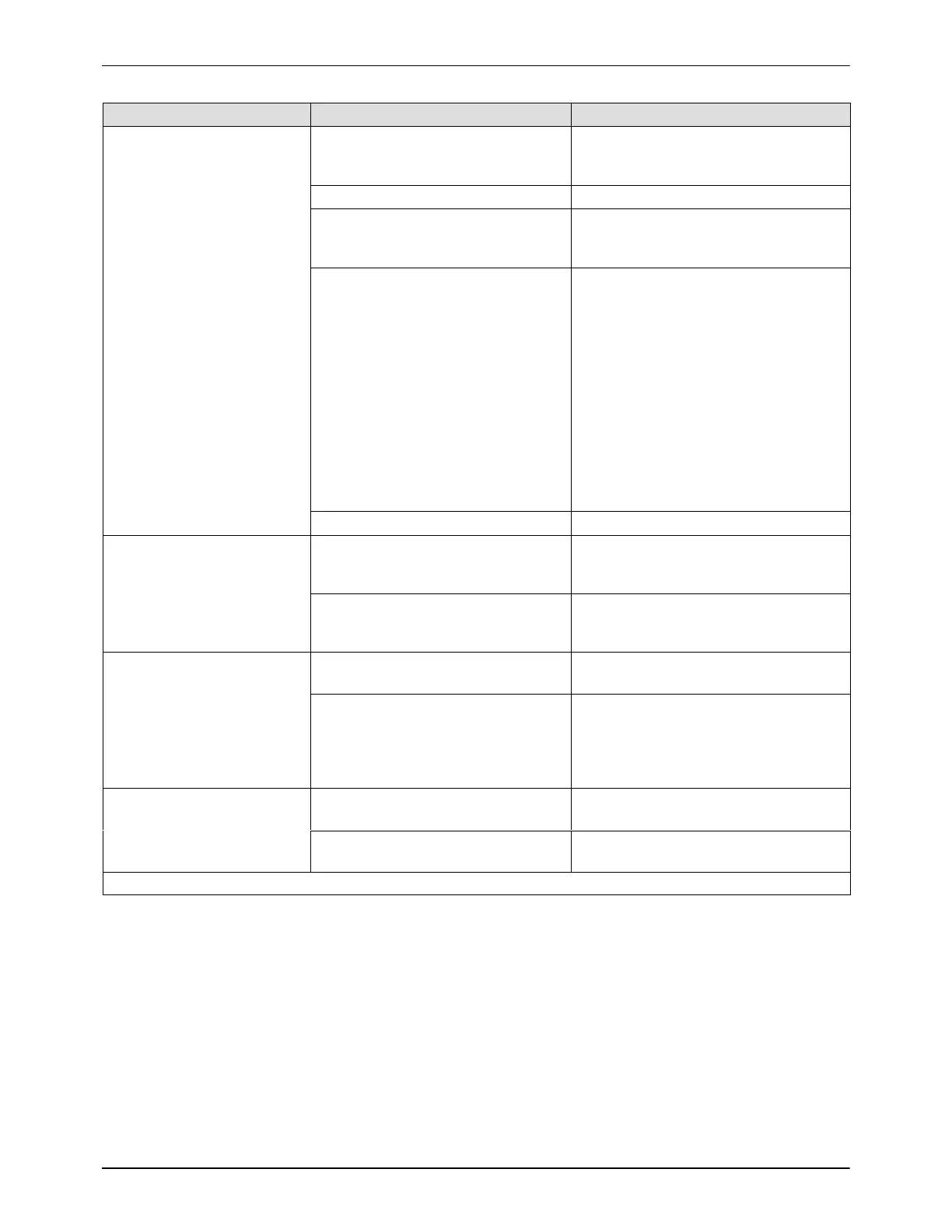

Corrective ActionPossible CauseProblem

6. Sieve or vibratory

table turned ON, but

no vibration

E−Stop button pressed Reset the E-Stop button.

Afterfilter exhaust fan not running Start the exhaust fan.

Sieve switch or wiring defective Check the switch and wiring.

Replace the switch or repair the

wiring as needed.

Sieve motor overload Overload occurs when motor

operates at higher amperage than

designed for.

Make sure nothing is preventing

motor vibration.

Check the motor and electrical

connections.

Check the motor internal weights for

proper adjustment.

Make sure the overload protector is

set to the proper limit.

Reset the overload.

Sieve motor failed Replace the sieve motor.

7. Powder buildup on

sieve screen

Screen not cleaned frequently

enough

Clean the sieve mesh at more

frequent intervals. Upgrade to

Vibrasonic sieve screen if necessary.

Screen mesh size too small for

powder being used

Use a sieve screen with a larger

mesh size. Upgrade to Vibrasonic

sieve screen if necessary.

8. Excessive sieve noise Sieve deck or discharge pan not

secure

Tighten the clamps securing the sieve

deck.

Knobs or clamps not tightened;

vibration isolators loose or

damaged; screen gasket damaged

Make sure the clamps are tight.

Check the isolators for looseness or

damage. Tighten the isolator

mounting screws. Check the screen

gasket and replace it if damaged.

9. Contaminants in feed

hopper powder

Sieve screen torn Replace the screen.

Sieve screen not thoroughly

cleaned before installation

Remove and clean the sieve screen.

Continued...

Loading...

Loading...