Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

Switching frequency of the motor current / motor reference point

In this chapter you can read about:

Following Error (Position Error) ...................................................................................... 186

Reduction of the current ripple ....................................................................................... 186

Motor parameters .......................................................................................................... 187

Changing the switching frequency and the reference point ............................................ 188

The higher the switching frequency, the better the quality of the current control. The

higher switching frequency reduces the dead time of the current control path as

well as the current control noise. Furthermore, thermal losses caused by current

ripple are reduced at higher switching frequencies.

Following Error (Position Error)

Too high following error (position error) during a movement

1) Setpoint Position

2) Position deviation = following error

3) Effective position

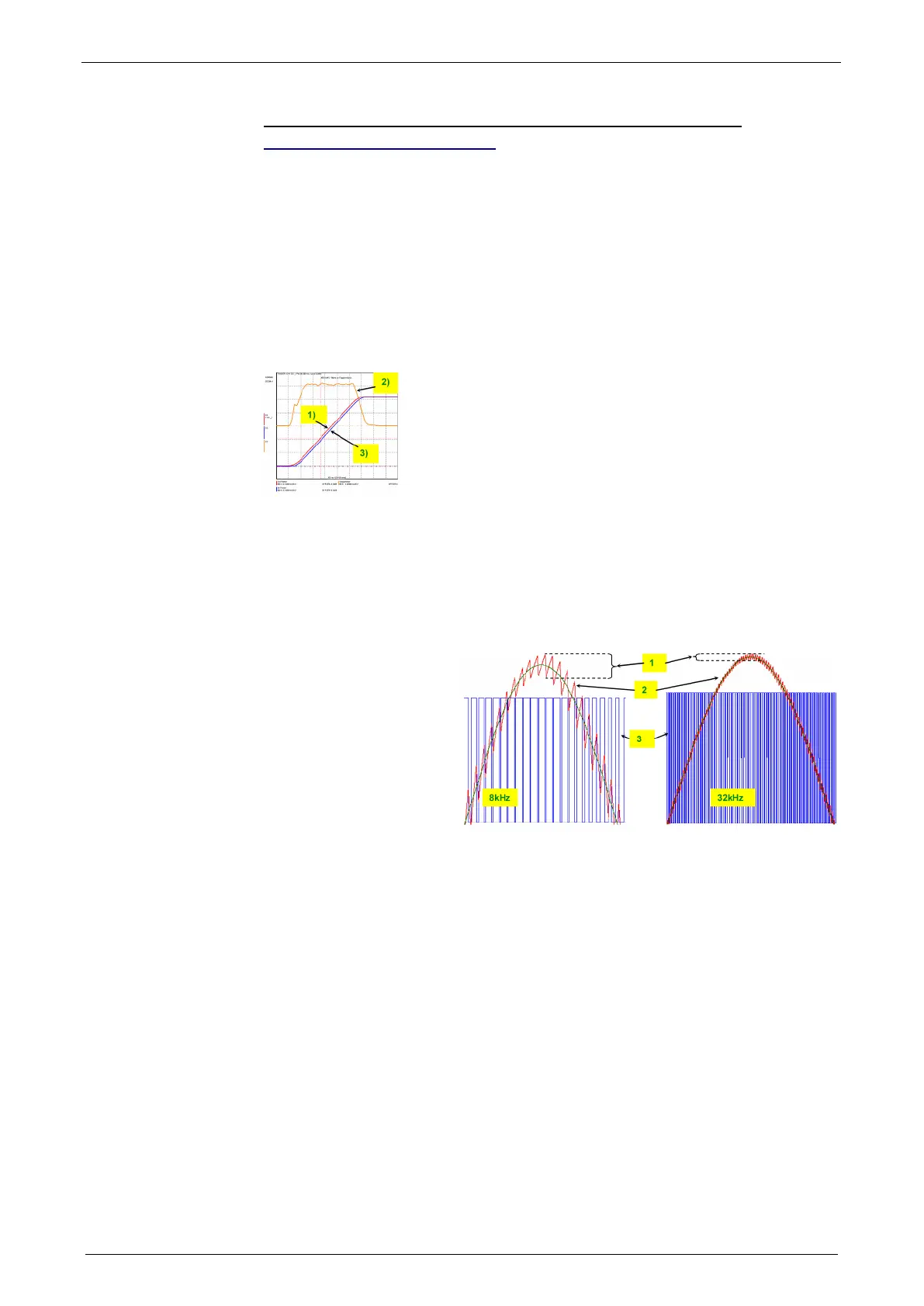

Reduction of the current ripple

Reduction of the current ripple of the phase current due to the higher switching

frequency

1: Current ripple

2: Phase current

3: PWM control

Please note that a high switching frequency means also high switching losses in

the power output stage of the controller. For this reason, you must consider

derated data of the servo controller for the drive design with higher switching

frequencies.

Loading...

Loading...