Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

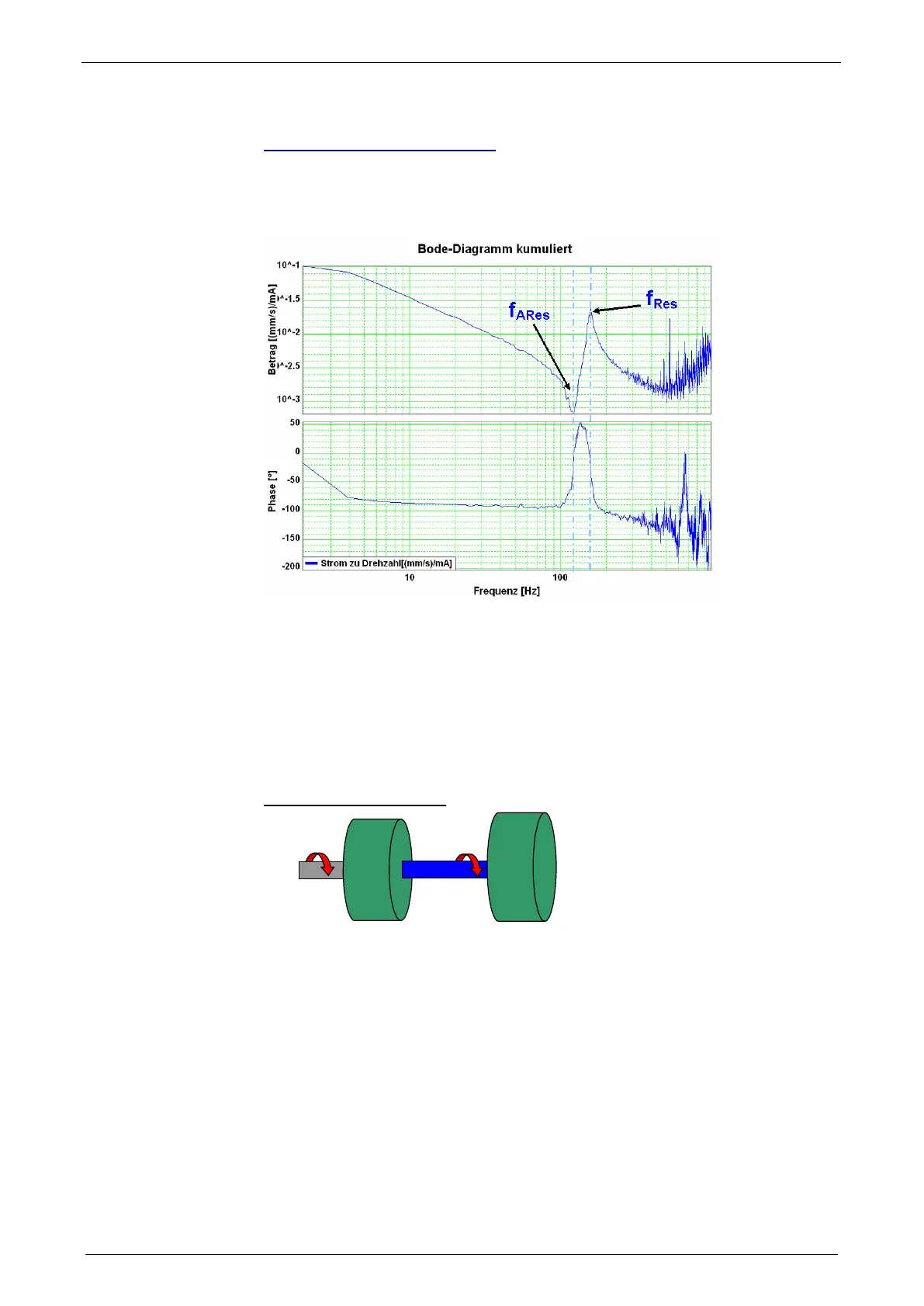

Resonance points and their causes

In this chapter you can read about:

Rotary two mass system ................................................................................................ 282

Linear two mass system ................................................................................................ 283

Toothed belt drive as two mass system ......................................................................... 284

Mechanical system with a resonance point

fARes: Anti resonance frequency

fRes: Resonance frequency

The displayed change of the frequency response (resonance point), has its cause

in a so-called two mass system (caused by the elastic coupling of two masses).

As, upon closer examination, each mechanic coupling shows a certain elasticity, it

is no the question if there is a resonance point, but at which frequency it is and how

well it is attenuated.

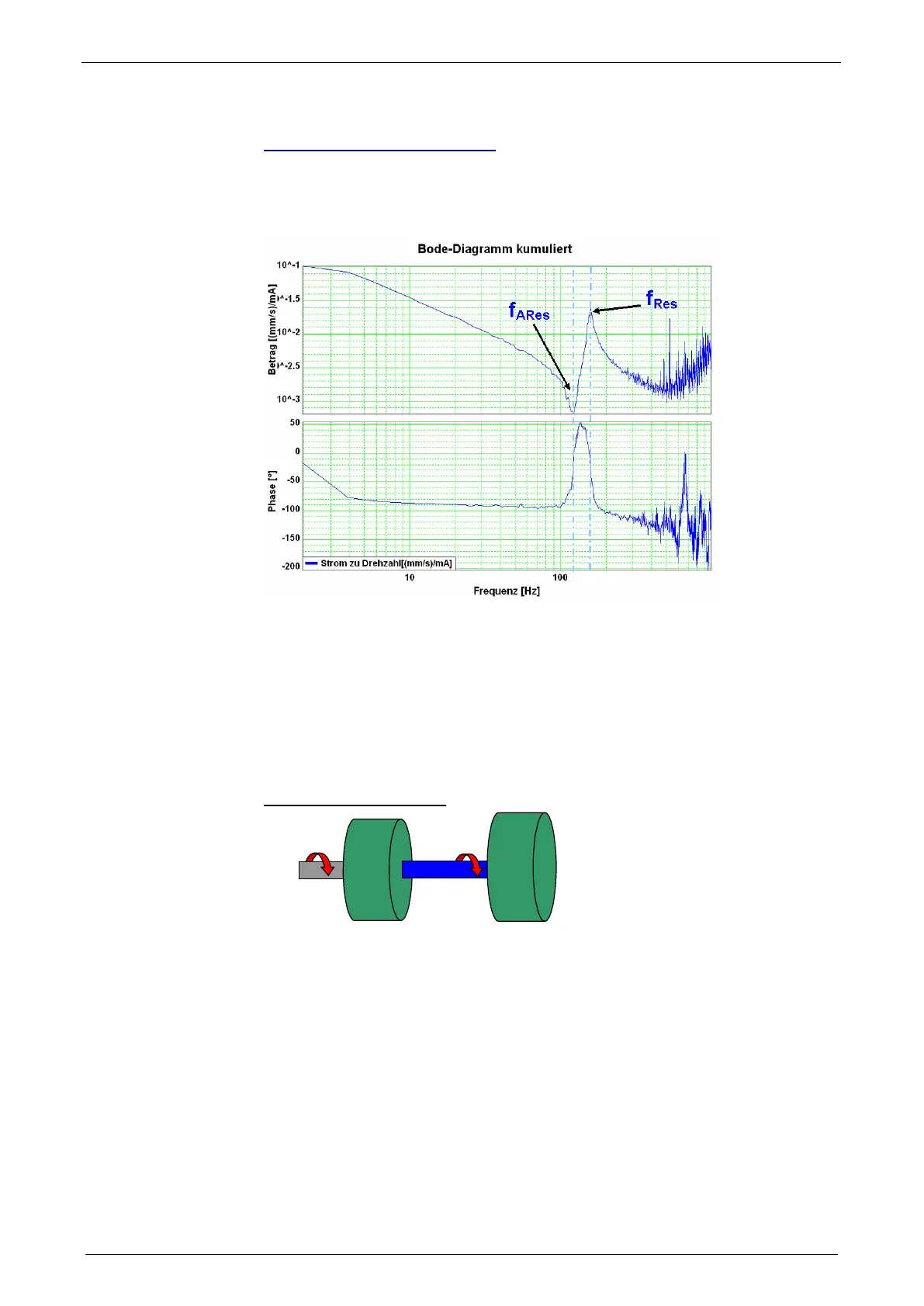

Rotary two mass system

The shown system corresponds for instance to a motor with a flywheel coupled via

a shaft. Hereby J1 corresponds to the motor moment of inertia and J2 to the

moment of inertia of the flywheel.

Loading...

Loading...