ComBricks User Manual v6.4.0 | January 18| © PROCENTEC 119/219

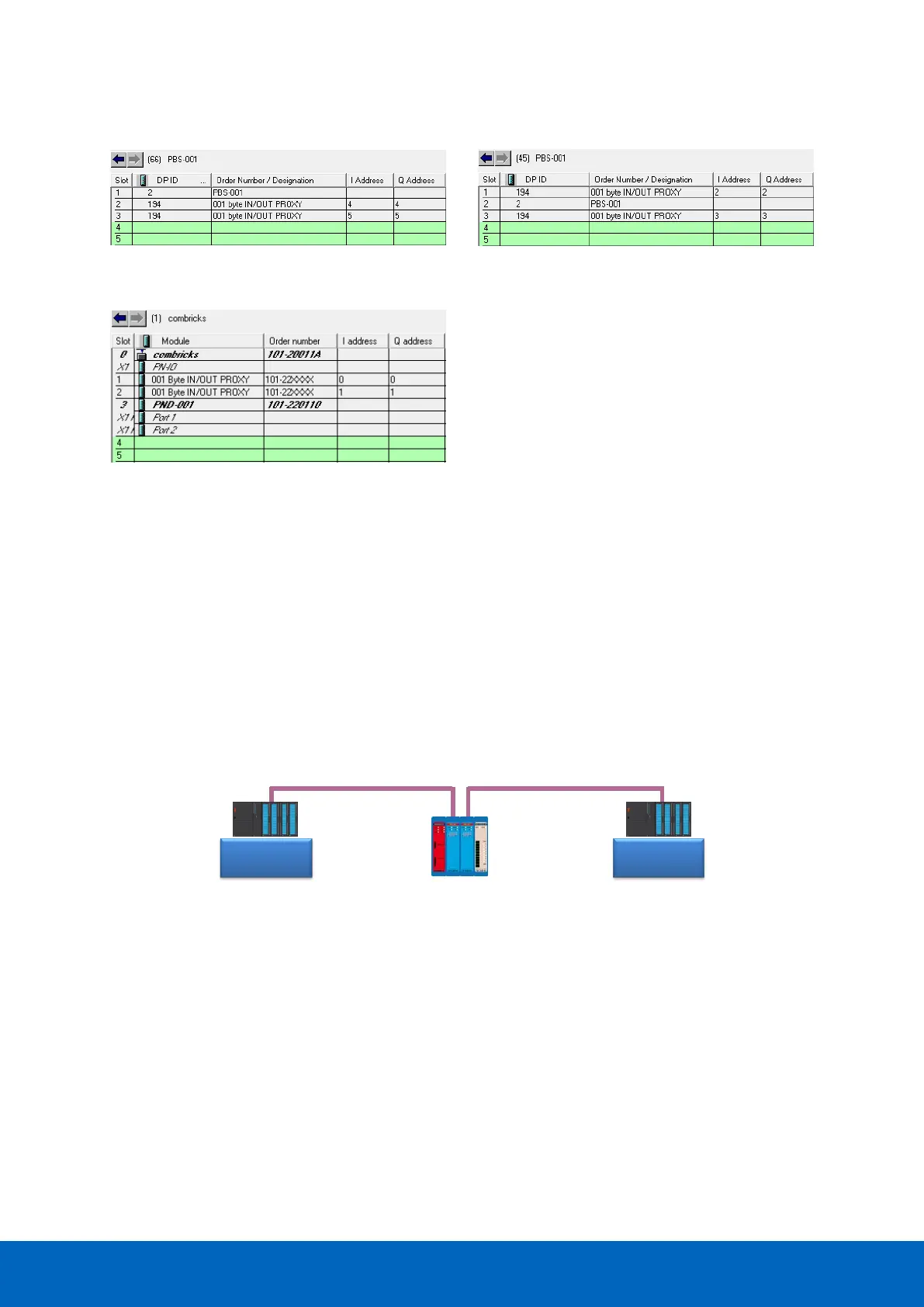

The configuration of the networks is as follows:

Fig. 76 - Configuration for PROFIBUS network 2

Fig. 77 - Configuration for network 3 (PROFINET)

Now the Inputs and Outputs of all networks can be sent to the I/O of the gateways in the PLC programs.

11.7 Data consistency

For some applications it is required to have consistent bytes, for example robot cells with X, Y and Z axis. The

polling of I/O in the PBS-001 and the processing in the Head Station and PLC is asynchronous which can cause

data inconsistency in the PLC, which means that not all bytes in a telegram are ‘up to date’. The use of

Consistent Gateways (defined in the GSD file) instead of normal Gateways offers a solution.

The paragraphs below describe a simple example of two PLC projects in Siemens Step7 which can be used in a

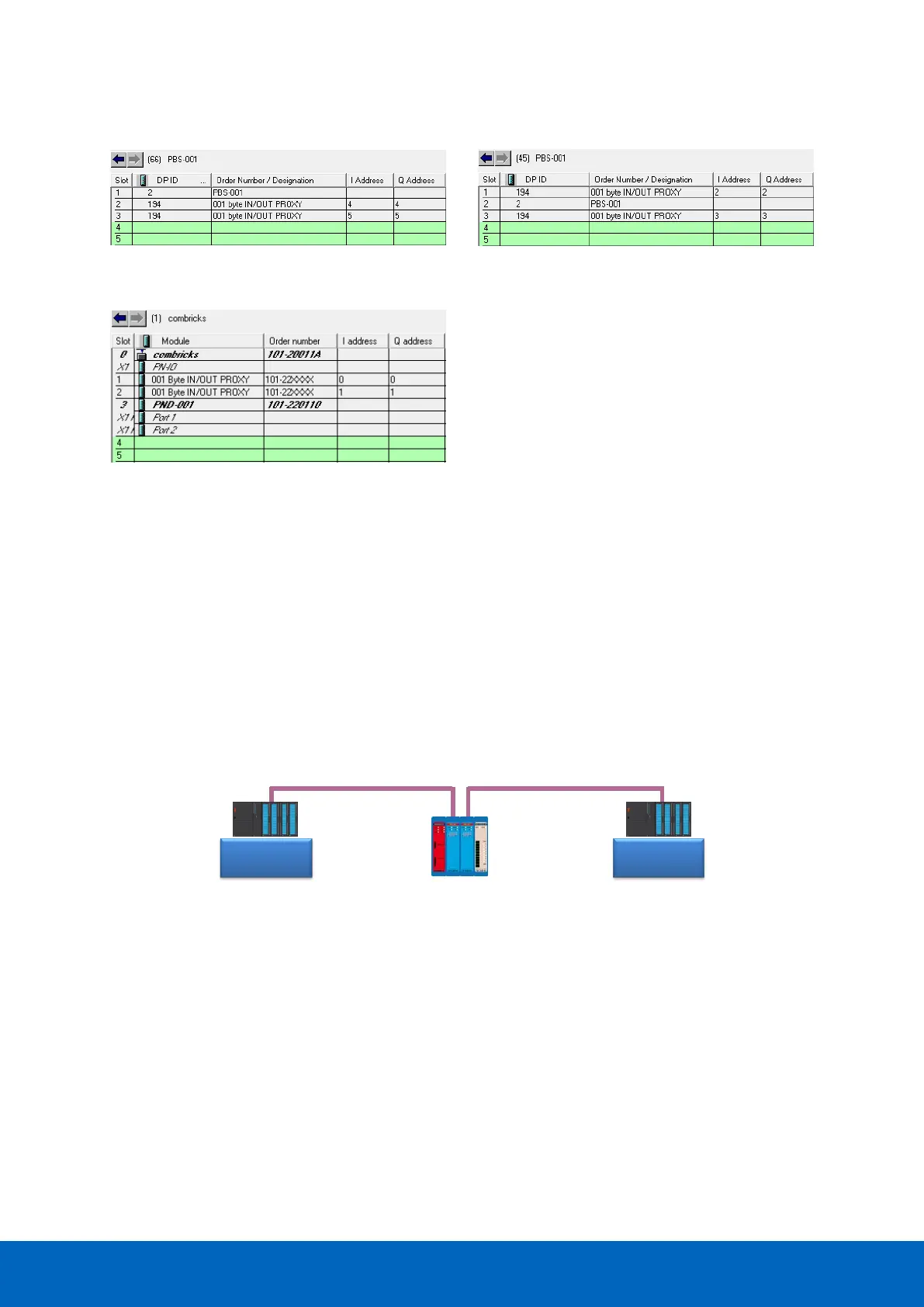

real byte-consistent project. Example setup:

The example shows how to transfer consistent data from network 2 to network 1. If the data is consistent,

nothing happens. If the data is not consistent, this is visualized by incrementing the outputs of the 8DO card

(assigned to network 1).

Loading...

Loading...